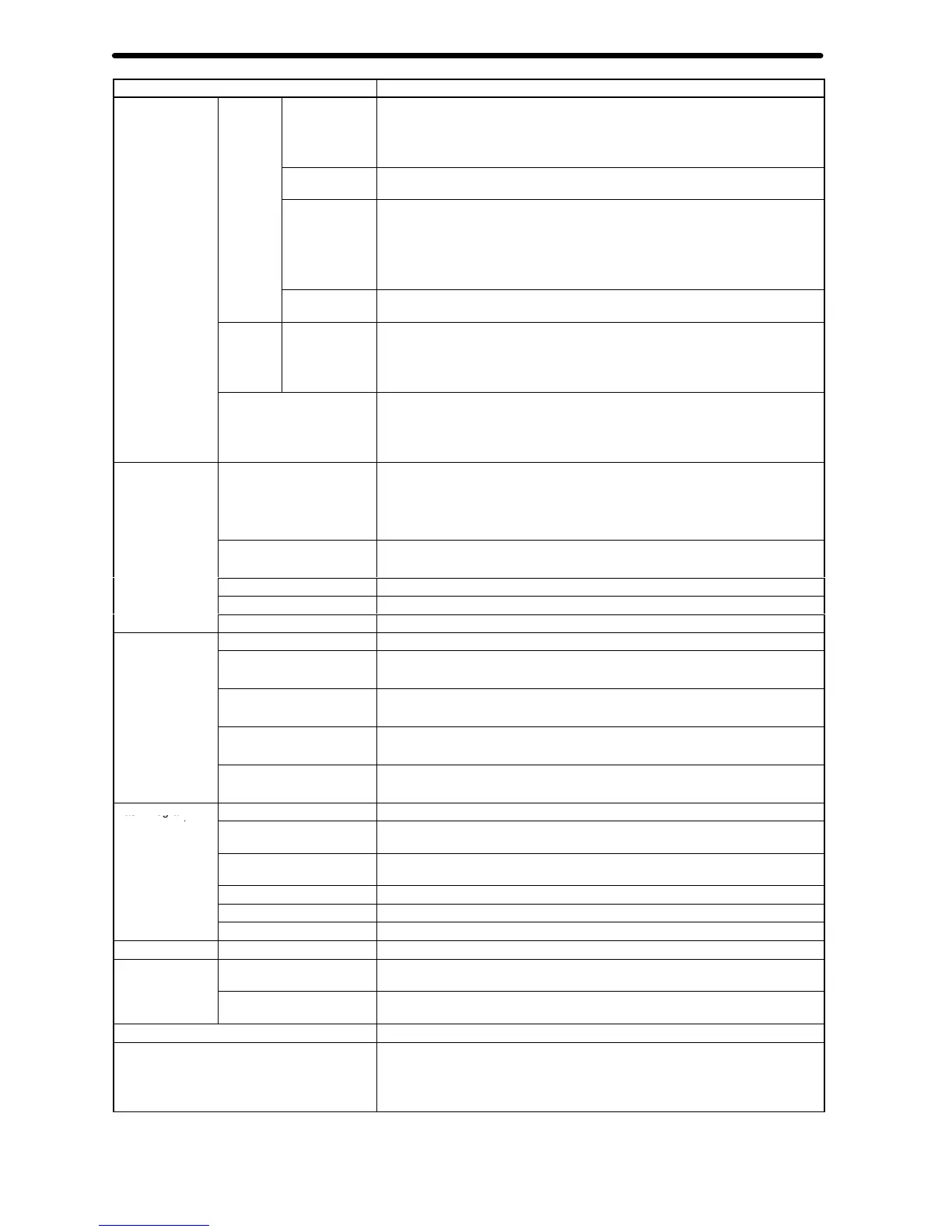

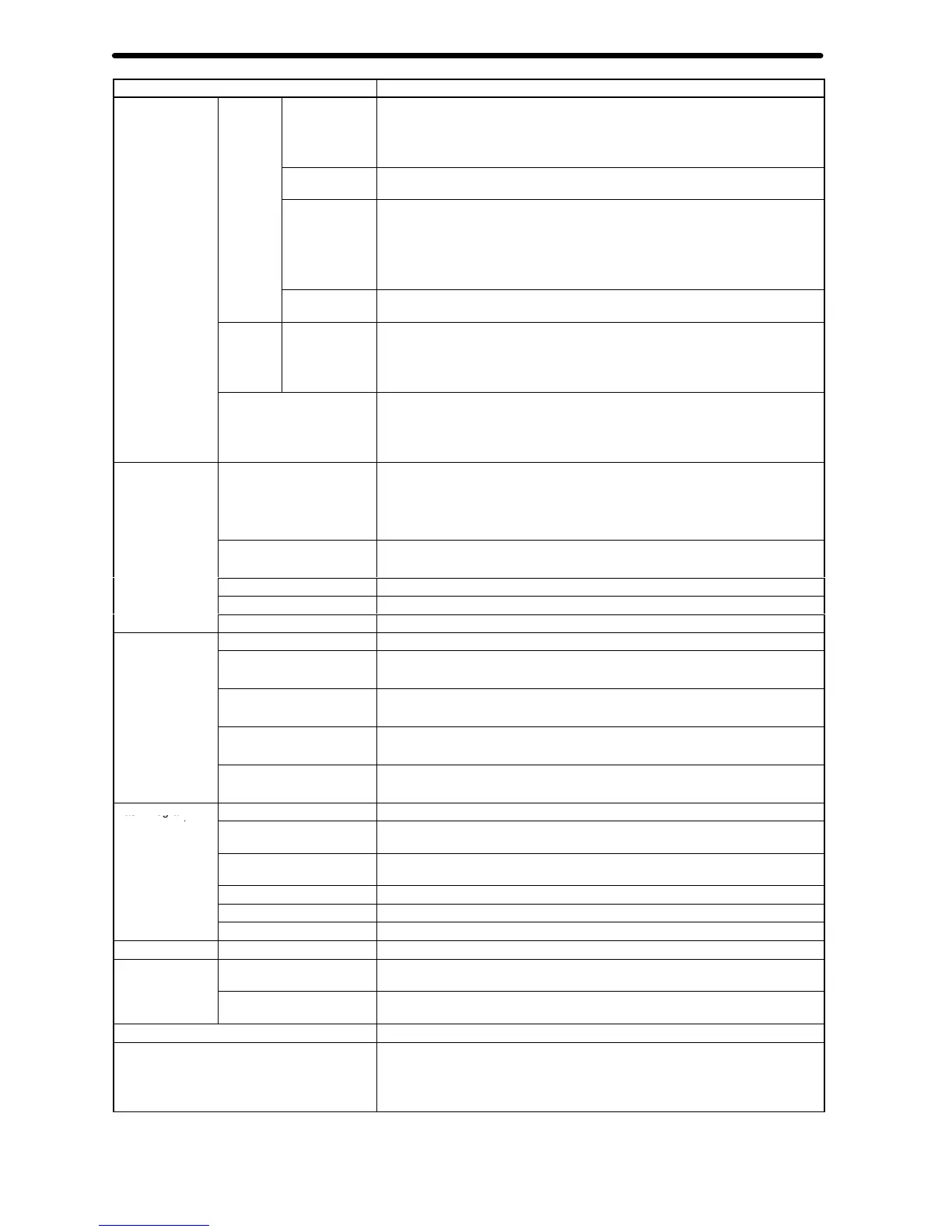

Motion Control Unit

Product Specifications

4

Model

number

C200H-MC221

External I/O

Input

Individual axis

control

The following signals are each provided for two axes:

CCW limit inputs

CW limit inputs

Origin proximity inputs

Emergency stop inputs

Servodriver

relationships

The following signal is provided for two axes:

Driver alarm signal

Encoder

Line receiver inputs

For two axes

250 kp/s max. before multiplication

Fixed at

×4

Note: When using a manual pulse generator (MPG), connect it to the Y

-axis encoder

input terminal. (X-axis + MPG)

General-

purpose inputs

2 points (for external start commands, etc.)

Output Servodriver

relationships

The following signals are each provided for two axes:

Speed command voltage output (

±

10 V)

Operation command output

SEN signal (for absolute encoder)

Driver alarm reset signal

Peripheral device

1 serial channel for T

eaching Box or MC Support Software (switchable using the

slide switch on the front panel)

T

eaching Box: 9,600 bits/s for RS-422

MS Support Software: 9,600 bits/s for RS-422 and RS-232C

Feed operations

Maximum rapid feed rate

Maximum feed rate for PTP operation

36.86 m/min under the following conditions:

Encoder resolution: 2,048 p/r

Motor speed: 4,500 r/m

Control unit: 0.001 mm/pulse

Maximum interpolation feed

rate

Maximum feed rate for interpolation operations

36.86 m/min under the same conditions as above

Rapid feed override

0% to 100.0% (Setting unit: 0.1%)

Interpolation feed override 0% to 199.9% (Setting unit: 0.1%)

Jog feed override

0% to 100.0% (Setting unit: 0.1%)

Axis control

Zone settings

Up to 8 zones/axis can be set.

Backlash correction Backlash for mechanical system

Can be set from 0 to 999 pulses.

In-position zone

Number of accumulated pulses for determining the positioning completed status

Can be set from 0 to 999 pulses.

Position loop gain

Servo system response adjustment gain

5 to 250 (1/s)

Position loop feed-forward

gain

Servo system response adjustment gain

0% to 100%

T

ask program

Number of tasks

2 max. (program execution units)

management

Number of programs

When 1 task is used:

100 max.

When 2 tasks are used:

50 max./task

Program capacity

When 1 task is used: 800 blocks max.

When 2 tasks are used: 400 blocks max./task

Position data capacity

2,000 positions max. (when only one axis is used) (A0000 to A1999)

Number of registers

32 (Mainly used for specifying position data numbers.) (E00 to E31)

Subroutine nesting

5 levels max.

Auxiliary function

M code

000 to 999

Saving program

data

MC Unit

MC programs, system parameters, and position data can be stored in the flash

memory in the MC Unit.

External peripheral devices

MC Support Software can be used to save data to a floppy disk or the hard disk at

the personal computer

.

Self-diagnostic function

Memory corruption is detected.

Error detection functions

Error counter warning, error counter over

, absolute encoder error detection, CPU

errors, communications errors (T

eaching Box), flash memory error

, EEPROM error,

software limit over error, phase-Z error

, overtravel, emergency stop, unit number

error

, driver alarm detection, driver reverse wiring detection, CPU Unit error

detection

Loading...

Loading...