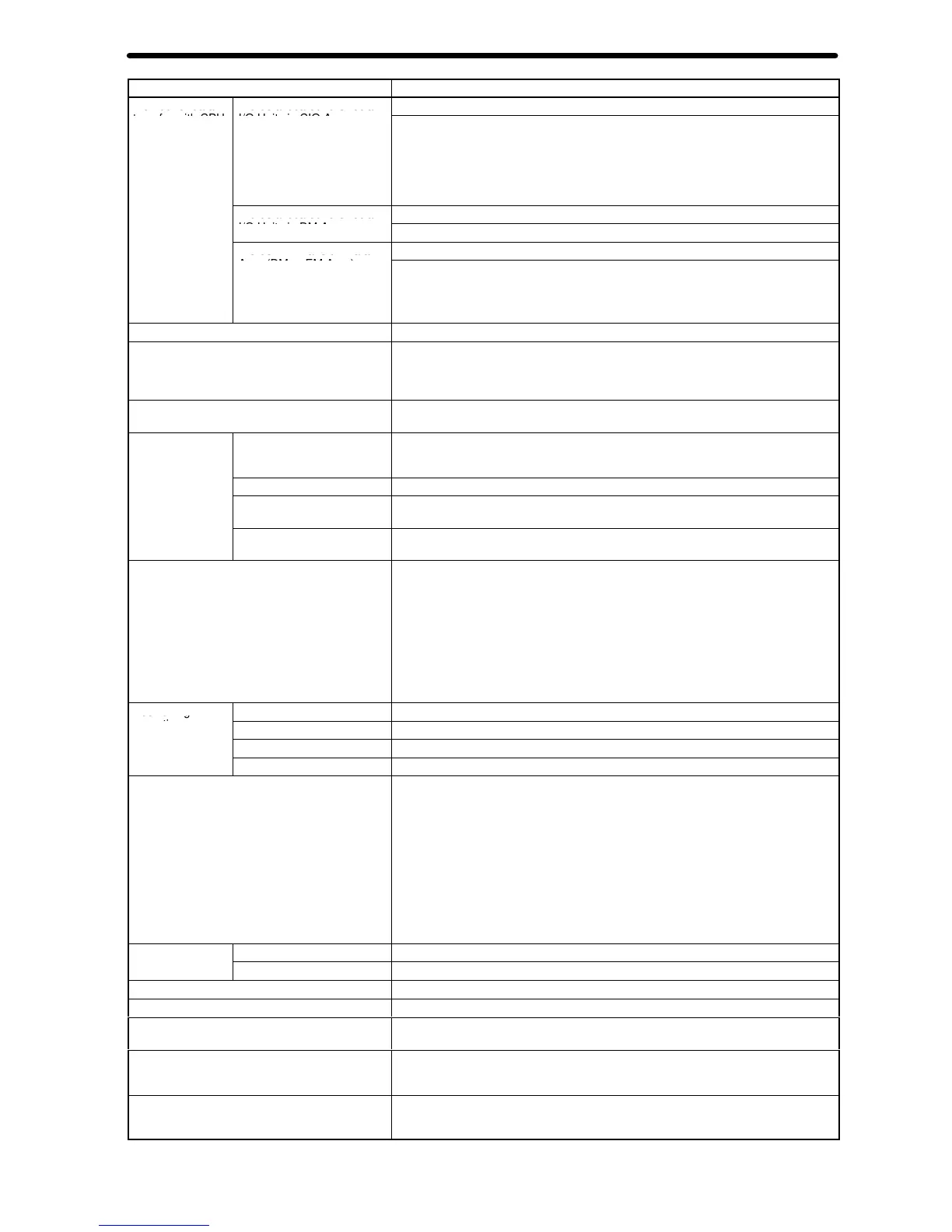

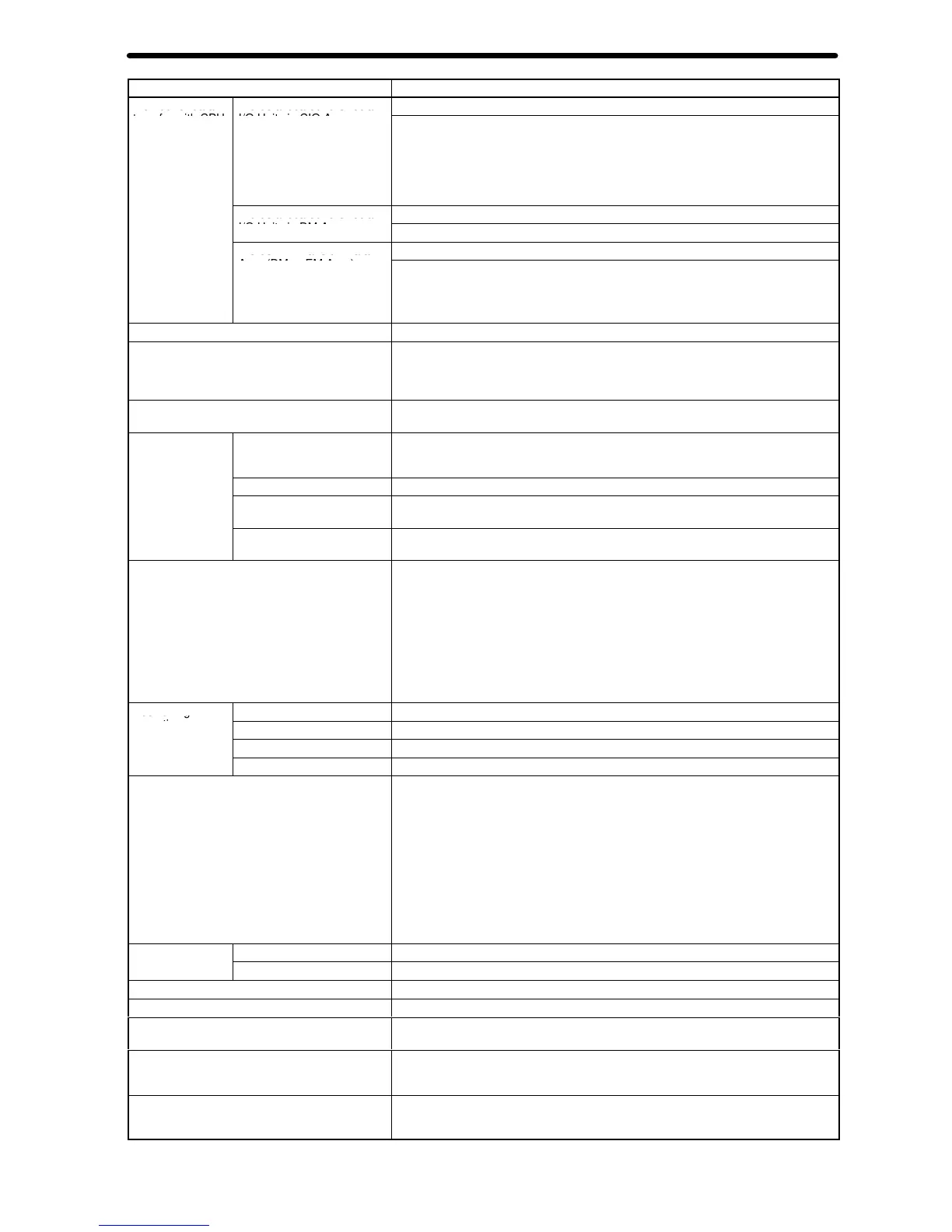

Product Specifications

Motion Control Unit

3

Model

number

C200H-MC221

Method for data

W

ords allocated to Special

20 words/Unit (uses 2 unit numbers.)

I/O Units in CIO Area

CPU Unit to MC Unit:

Program numbers, cycle start (MC program operation command), origin search

command, automatic/manual mode switching, etc.

MC Unit to CPU Unit:

Status: Positioning completed, zones, busy flag, etc.

Monitor data: Present position, error codes, M codes, etc.

W

ords allocated to Special

2 words used out of 100 words allocated

I/O Units in DM Area

Expansion Data words are specified in initial settings.

W

ords in Expansion Data

Area (DM or EM Area)

CPU Unit to MC Unit:

Data transfer area specifications, present position preset values, etc.

MC Unit to CPU Unit:

System error codes, task error codes, ef

fective program numbers, etc.

Controlled servodrivers Analog input servodrivers (Example: OMRON OMNUC H, M, or U Series)

Encoder interface

Line receiver input; maximum response frequency: 250 kp/s (before multiplication)

Pulse ratio: 4 (fixed)

Note: The applicable absolute encoder is the OMRON OMNUC U Series.

Built-in program language

G language (Started by receiving a start command from the CPU Unit ladder

diagram program.)

Control

Control method

Speed reference voltage output-type semi-closed loop system, using incremental

and absolute encoder inputs (automatic trapezoidal or S-curve

acceleration/deceleration method)

Number of controlled axes

2 axes max.

Number of simultaneously

controlled axes

2 axes max.

PTP (independent) control Multitasking can be used to execute independent operating modes and programs for

each axis.

Automatic/Manual Mode (for each task)

Automatic Mode: Mode for executing MC program created in G language.

Manual Mode: Mode for executing manual commands from CPU Unit (PC interface

area) or T

eaching Box.

Note: The Automatic and Manual Modes are switched according to the PC interface

area of the CPU Unit.

There are a total of 10 Manual Mode commands, including origin search, reference

origin return, jogging, and present position preset.

The operation command (cycle start) is started in Automatic Mode using the PC

interface area of the CPU Unit.

Positioning

Independent

Independent operations for a maximum of two axes

operations

Linear interpolation

Linear interpolation for a maximum of two axes

Circular interpolation

Circular interpolation for a maximum of two axes on a plane.

Interrupt feeding

Operations for each axis

Position specification method Operating positions can be specified in MC programs by using one of the following

three methods.

Direct Specification of Coordinate V

alues

Example: When G00 X100 is specified with absolute specification, the X axis moves

to a position of 100.

Address Specification of Position Data

Example: When G00 XA0000 is specified, the axis moves to the position set as

position data address 0000.

Indirect Register Specification

Example: When G00 X(E00) is specified, the X axis moves to the position set as the

position data address in the E00 indirect register

.

Control unit

Minimum setting unit

1, 0.1, 0.01, 0.001, 0.0001

Units

mm, inch, degree, pulse (There is no unit conversion function.)

Maximum command value

–39,999,999 to +39,999,999

Acceleration/deceleration curve

T

rapezoidal or S-curve (Can be selected for each axis.)

Acceleration/deceleration time

Individual acceleration/deceleration settings possible: 0 to 9,998 ms (2-ms

increments)

Speed reference

Speed control for a maximum of two axes.

When the unit is pulses, the setting range is from 1 p/s to 1,000 kp/s (after

multiplication by 4).

Feed rate (PTP operation) specification method

Can be set for each axis.

Feed rate = High speed

×

Override value/100

Real-time speed can be changed by altering the override value.

Loading...

Loading...