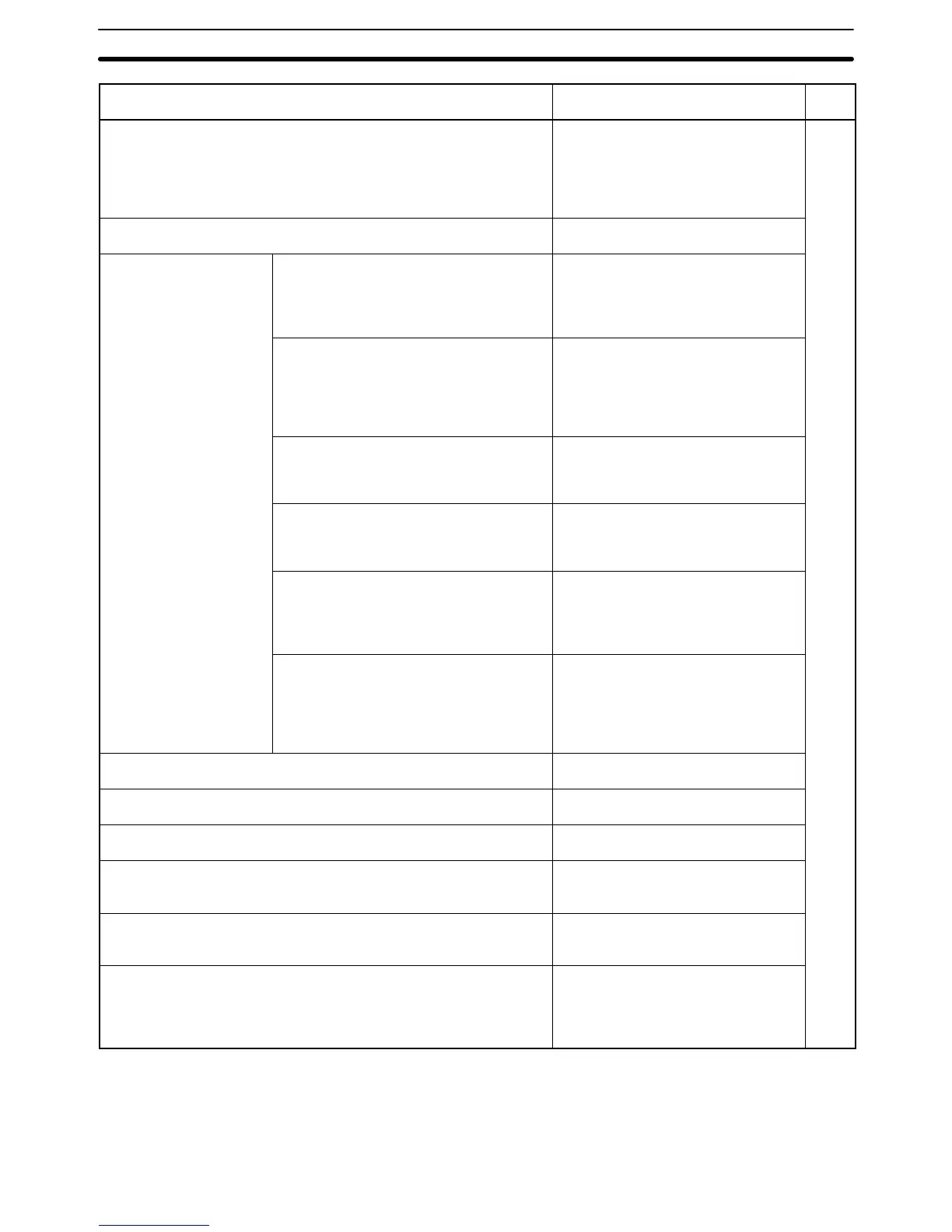

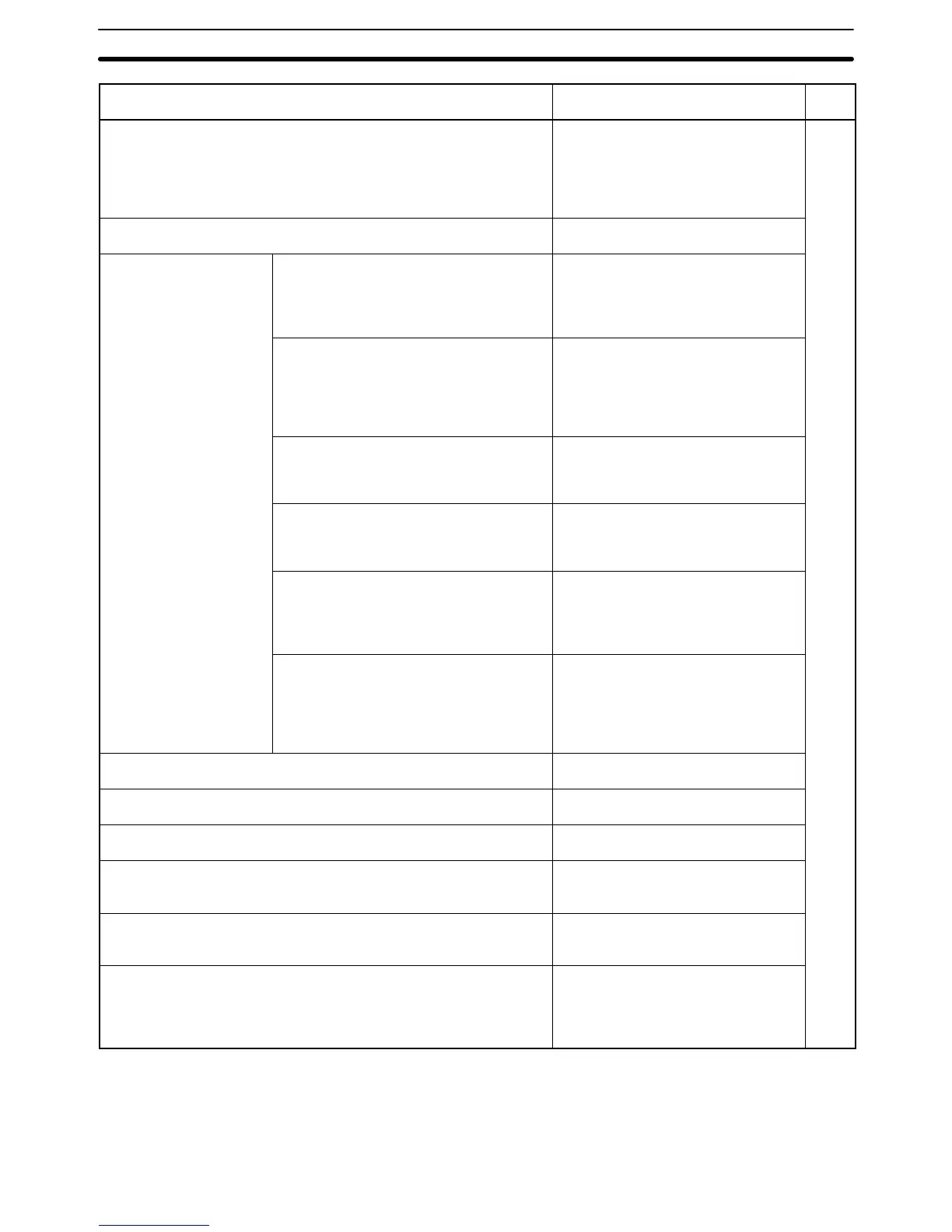

1-4SectionFunctions Listed by Usage

19

Usage Refer

to

Function

Multiply the input pulse frequency from a high-speed counter by a fixed

multiple, convert that value to an analog value, and output as an

analog output.

(For example, synchronizing the speed of a supply conveyor with the

rotational position of the main piece of equipment (such as a label

inserter) measured by an analog input.)

Pulse synchronization and analog

output function

W353

Reliably receive input pulses with an ON-time shorter than the cycle

time (such as inputs from a photomicrosensor).

Quick-response input function

Interrupt functions

Execute a special process very quickly

when an input goes ON.

(For example, operating a cutter when an

interrupt input is received from a Proximity

Switch or Photoelectric Switch.)

Interrupt input (interrupt input mode)

Count input ON pulses and execute a

special process very quickly when the

count reaches the preset value.

(For example, stopping the supply feed

when a preset number of workpieces have

passed through the system.)

Interrupt input (counter mode)

Execute a special process at a preset

count value.

(For example, cutting material very

precisely at a given length.)

High-speed counter interrupt

generated when the count matches

the set value.

Execute a special process when the count

is within a preset range.

(For example, sorting material very quickly

when it is within a given length range.)

High-speed counter interrupt

generated when the count is within the

set range.

Execute a special process when a timer

times out.

(For example, stopping a conveyor at very

precise time (independent of the cycle

time) after the workpiece is detected.)

Interval timer interrupt

(One-shot mode)

Repeat a special process at regular

intervals.

(For example, the speed of a sheet feeder

can be monitored by measuring the input

signal from an encoder at regular intervals

and calculating the speed.)

Interval timer interrupt

(Scheduled interrupt mode)

Perform simple positioning by outputting pulses to a motor driver that

accepts pulse-train inputs.

Pulse output function

Use a variable duty-ratio output to perform time-allocated temperature

control.

Analog input + Variable duty-ratio

output pulse function (PWM(––))

Easily set and fine-tune settings such as the low-speed feed rate when

a conveyor is temporarily stopped.

Analog controls

Receive an analog input and output an analog output. Analog I/O Unit

(Connect the Analog I/O Unit to the

CPU Unit.)

Receive temperature sensor input directly at the PC. Temperature Sensor Unit

(Connect the Temperature Sensor

Unit to the CPU Unit.)

Reduce required wiring, space, and PC load by controlling equipment

with a few low-capacity PCs dispersed near the equipment rather than

a single, large, centralized PC.

(Create a remote I/O link with a CompoBus/S Master and CompoBus/S

Slaves.)

CompoBus/S I/O Link Unit

(Connect the CompoBus/S I/O Link

Unit to the CPU Unit.)

Loading...

Loading...