OPERATION

GENERAL

ONAN DDB Series electric generating sets are given a

complete running test under various load conditions

and are thoroughly checked before leaving the fac-

tory. Inspect your unit closely for loose or missing

parts and damage which may have occurred in transit.

Tighten loose parts, replace missing parts and repair

any damage before putting set into operation.

PRESTART

SERVICING

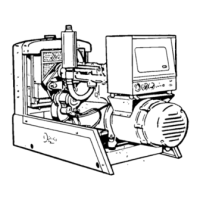

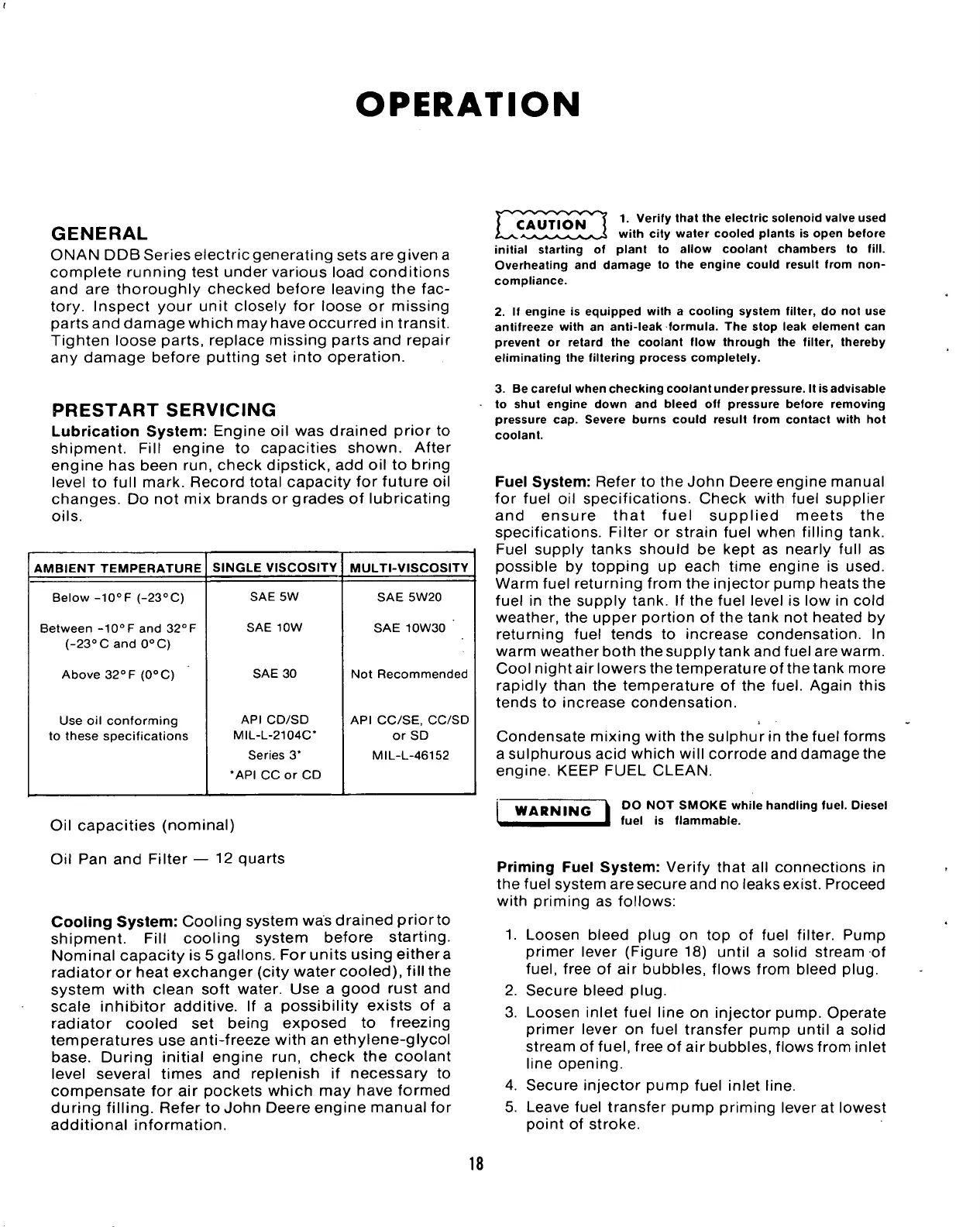

Lubrication System: Engine oil was drained prior to

shipment. Fill engine to capacities shown. After

engine has been run, check dipstick, add oil to bring

level to full mark. Record total capacity for future oil

changes. Do not mix brands or grades of lubricating

oils.

AMBIENT TEMPERATURE

SINGLE VISCOSITY MULTI-VISCOSITY

Below -10

o

F (-23

0

C)

SAE 5W

SAE 5W20

Between -10° F and 32° F

SAE 10W

SAE 10W30

(-23

0

C

and 0

o

C)

Above 32° F (0°C)

SAE 30

Not Recommended

Use oil conforming

API CD/SD

API CC/SE, CC/SD

to these specifications

MIL-L-2104C* or SD

Series 3* MIL-L-46152

*API CC or CD

Oil capacities (nominal)

Oil Pan and Filter — 12 quarts

Cooling System: Cooling system was drained priorto

shipment. Fill cooling system before starting.

Nominal capacity is 5 gallons. For units using eithera

radiator or heat exchanger (city water cooled), fill the

system with clean soft water. Use a good rust and

scale inhibitor additive. If a possibility exists of a

radiator cooled set being exposed to freezing

temperatures use anti-freeze with an ethylene-glycol

base.

During initial engine run, check the coolant

level several times and replenish if necessary to

compensate for air pockets which may have formed

during filling. Refer to John Deere engine manual for

additional information.

r^^J^j^^l

1. Verify that the electric solenoid valve used

L^^^^^^X

with city water cooled plants is open before

initial starting of plant to allow coolant chambers to

fill.

Overheating and damage to the engine could result from

non-

compliance.

2.

If engine is equipped with a cooling system filter, do not use

antifreeze with an anti-leak formula. The stop leak element can

prevent or retard the coolant flow through the filter, thereby

eliminating the filtering process completely.

3. Be careful when checking coolantunderpressure. Itis advisable

to shut engine down and bleed off pressure before removing

pressure cap. Severe burns could result from contact with hot

coolant.

Fuel System: Refer to the John Deere engine manual

for fuel oil specifications. Check with fuel supplier

and ensure that fuel supplied meets the

specifications. Filter or strain fuel when filling tank.

Fuel supply tanks should be kept as nearly full as

possible by topping up each time engine is used.

Warm fuel returning from the injector pump heats the

fuel in the supply tank. If the fuel level is low in cold

weather, the upper portion of the tank not heated by

returning fuel tends to increase condensation. In

warm weather both the supply tank and fuel are warm.

Cool nightairlowersthetemperatureof thetank more

rapidly than the temperature of the

fuel.

Again this

tends to increase condensation.

Condensate mixing with the sulphur in the fuel forms

a sulphurous acid which will corrode and damage the

engine. KEEP FUEL CLEAN.

WARNING

DO NOT SMOKE while handling

fuel.

Diesel

fuel is flammable.

Priming Fuel System: Verify that all connections in

the fuel system are secure and no leaks exist. Proceed

with priming as follows:

1.

Loosen bleed plug on top of fuel filter. Pump

primer lever (Figure 18) until a solid stream of

fuel,

free of air bubbles, flows from bleed plug.

2.

Secure bleed plug.

3. Loosen inlet fuel line on injector pump. Operate

primer lever on fuel transfer pump until a solid

stream of

fuel,

free of air bubbles, flows from inlet

line opening.

4.

Secure injector pump fuel inlet line.

5. Leave fuel transfer pump priming lever at lowest

point of stroke.

18

Loading...

Loading...