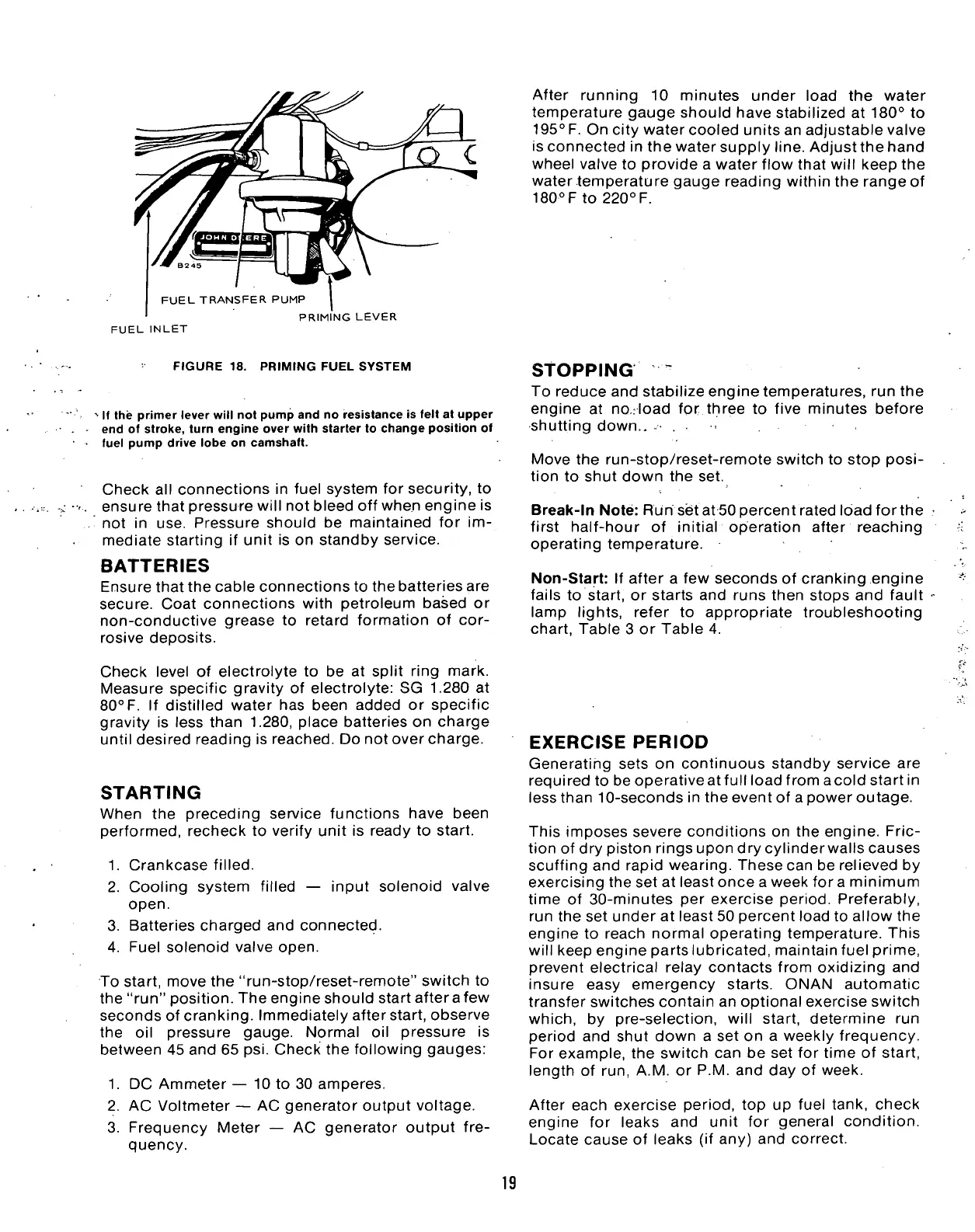

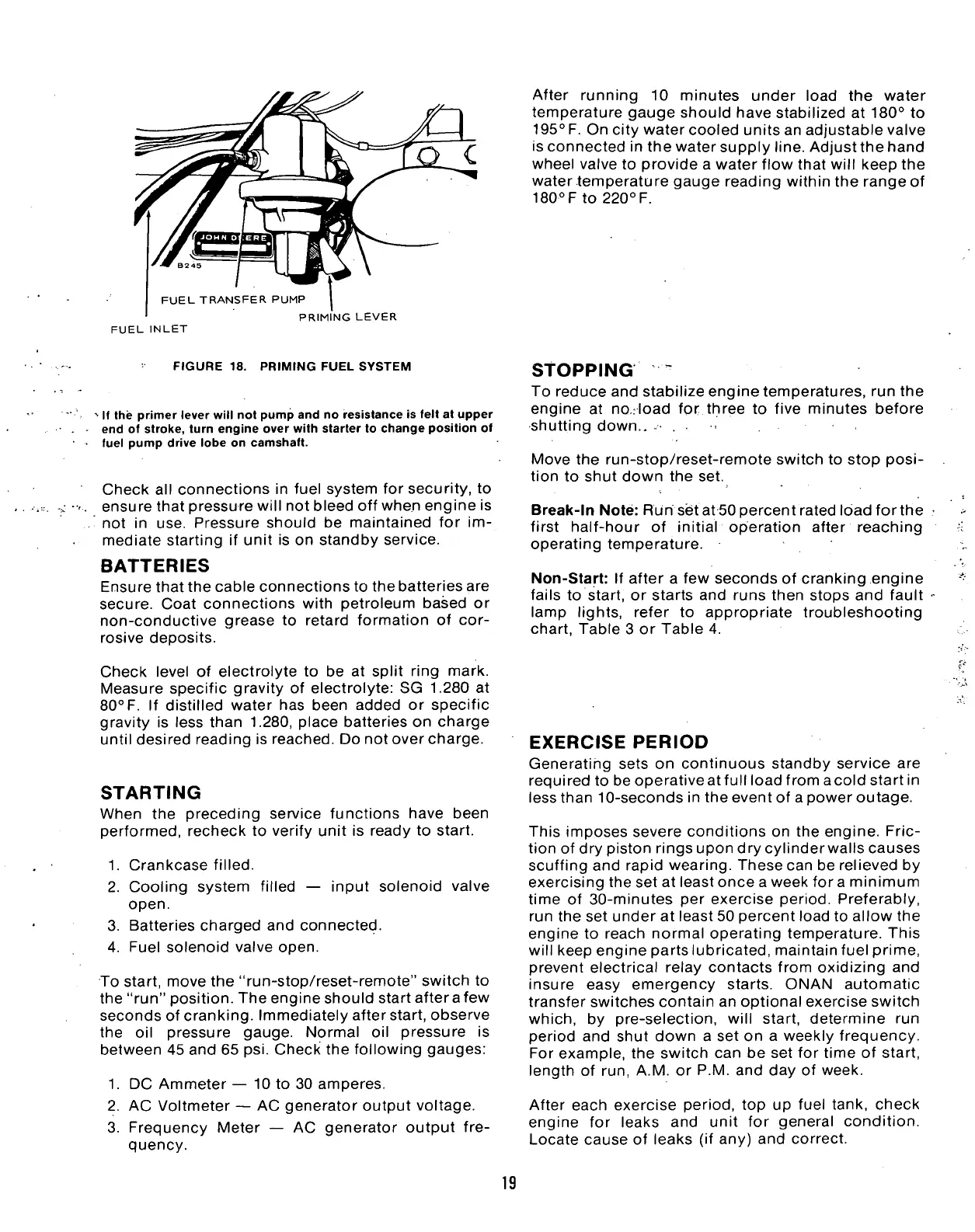

FUEL TRANSFER PUMP

PRIMING LEVER

After running 10 minutes under load the water

temperature gauge should have stabilized at 180° to

195° F. On city watercooled units an adjustable valve

is connected in the water supply line. Adjust the hand

wheel valve to provide a water flow that will keep the

water temperatu re gauge reading within the range of

180

o

F to 220° F.

FUEL INLET

FIGURE 18. PRIMING FUEL SYSTEM

»II the primer lever will not pump and no resistance is lelt at upper

end of stroke, turn engine over with starter to change position of

fuel pump drive lobe on camshaft.

Check all connections in fuel system for security, to

ensure that pressure will not bleed off when engine is

not in use. Pressure should be maintained for im-

mediate starting if unit is on standby service.

BATTERIES

Ensure that the cable connections to the batteries are

secure. Coat connections with petroleum based or

non-conductive grease to retard formation of cor-

rosive deposits.

Check level of electrolyte to be at split ring mark.

Measure specific gravity of electrolyte: SG 1.280 at

80° F. If distilled water has been added or specific

gravity is less than

1.280,

place batteries on charge

until desired reading is reached. Do not over charge.

STARTING

When the preceding service functions have been

performed,

recheck to verify unit is ready to start.

1.

Crankcase filled.

2.

Cooling system filled — input solenoid valve

open.

3. Batteries charged and connected.

4.

Fuel solenoid valve open.

To start, move the "run-stop/reset-remote" switch to

the "run" position. The engine should start afterafew

seconds of cranking. Immediately after start, observe

the oil pressure gauge. Normal oil pressure is

between 45 and 65 psi. Check the following gauges:

1.

DC Ammeter — 10 to 30 amperes.

2.

AC Voltmeter — AC generator output voltage.

3. Frequency Meter — AC generator output fre-

quency.

STOPPING "

To reduce and stabilize engine temperatures, run the

engine at no.:load for three to five minutes before

shutting down..

Move the run-stop/reset-remote switch to stop

posi-

tion to shut down the set.

Break-In Note: Run set at 50 percent rated load forthe

first half-hour of initial operation after reaching

operating temperature.

Non-Start: If after a few seconds of cranking engine

fails to start, or starts and runs then stops and fault

lamp lights, refer to appropriate troubleshooting

chart, Table 3 or Table 4.

EXERCISE

PERIOD

Generating sets on continuous standby service are

required to be operative at full load from

a

cold start in

less than 10-seconds in the event of a power outage.

This imposes severe conditions on the engine. Fric-

tion of dry piston rings upon dry cylinderwalls causes

scuffing and rapid wearing. These can be relieved by

exercising the set at least once a week for a minimum

time of 30-minutes per exercise period. Preferably,

run the set under at least 50 percent load to allow the

engine to reach normal operating temperature. This

will keep engine parts lubricated, maintain fuel prime,

prevent electrical relay contacts from oxidizing and

insure easy emergency starts. ONAN automatic

transfer switches contain an optional exercise switch

which,

by pre-selection, will start, determine run

period and shut down a set on a weekly frequency.

For example, the switch can be set for time of start,

length of run, A.M. or P.M. and day of week.

After each exercise period, top up fuel tank, check

engine for leaks and unit for general condition.

Locate cause of leaks (if any) and correct.

19

Loading...

Loading...