OPTIMUM

MASCHINEN - GERMANY

Assembly

30 / 11 / 2007 Page 21Assembly Add-on kit D240/D280 ; Version 1.3.3

© 2007

GB

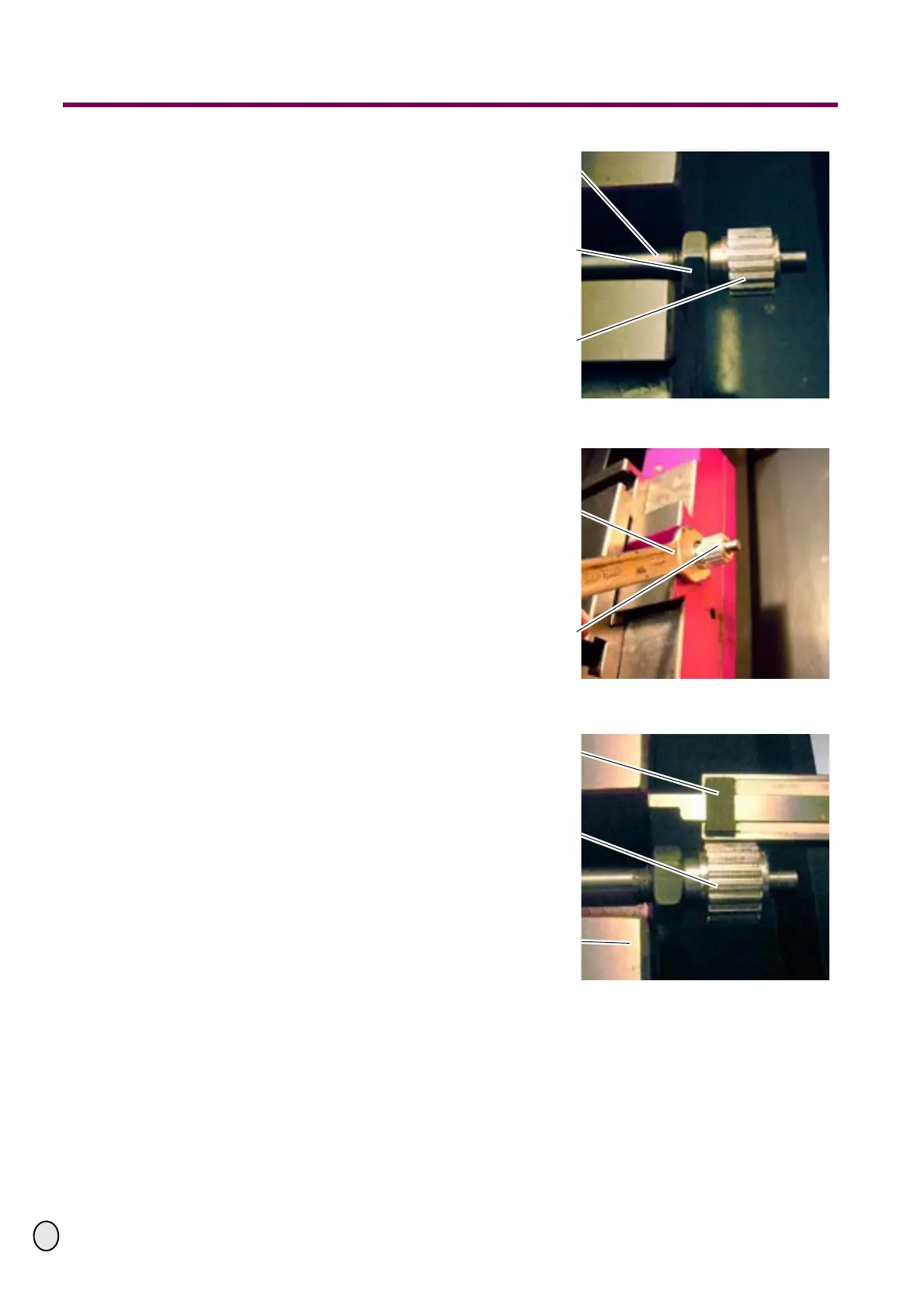

£ Screw the nut (part 22) onto the

shaft elongation.

£ Screw the pulley (part 8) onto the

shaft elongation.

£ In order to be able to adjust the axis

distance more easily later on, screw

the nut and the pulley as much

inside as possible.

Illustr.: 4-36: Nut on shaft elongation

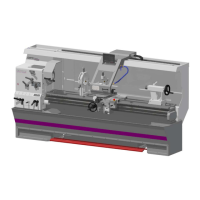

£ Counter the nut on the shaft elonga-

tion with a fork wrench.

£ To facilitate the countering to can

hold fast the handwheel of the com-

pound slide.

Illustr.: 4-37: Counter nut

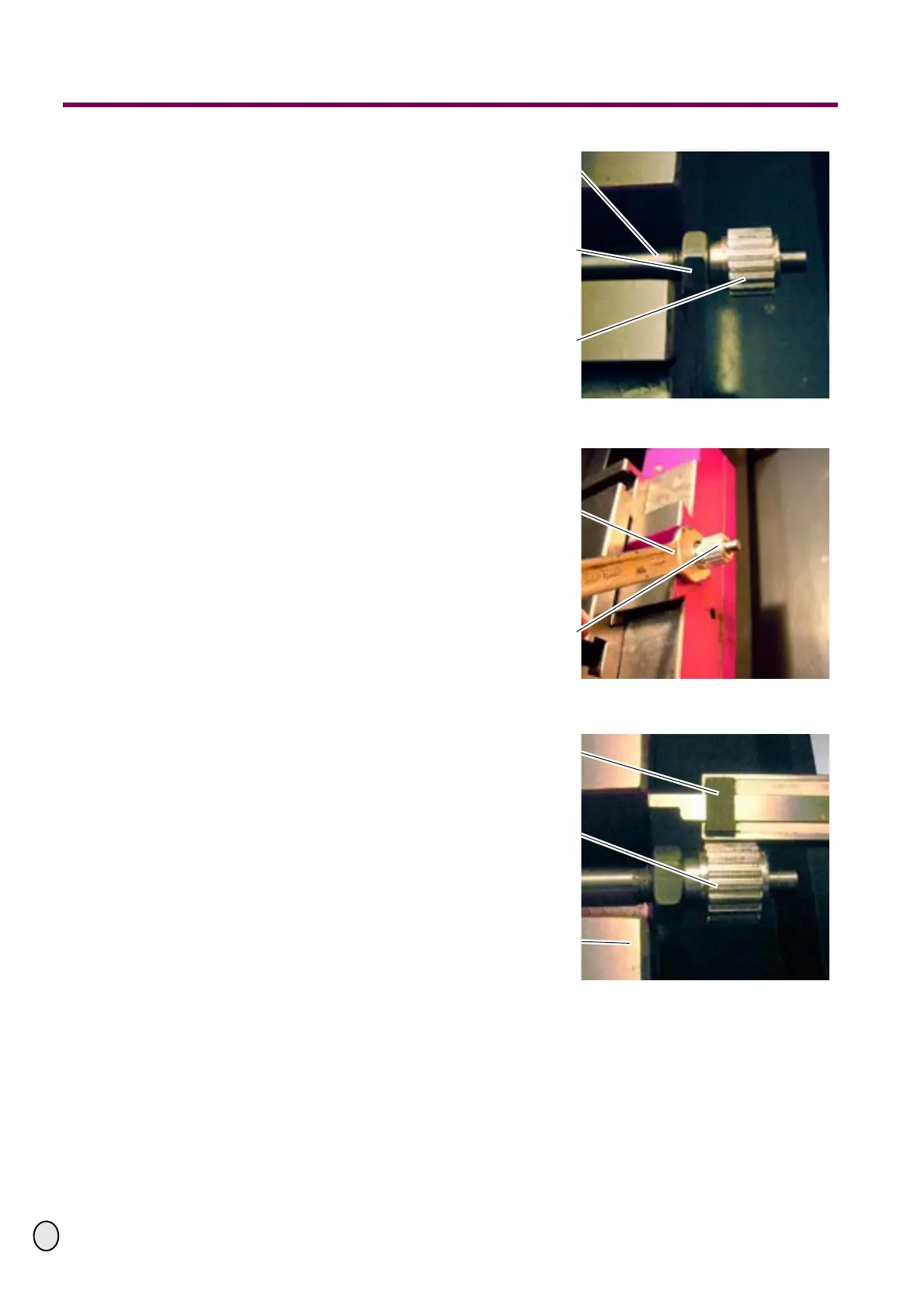

£ Measure the distance from the inner

edge of the pulley to the lathe slide.

£ Have the measured distance firmly

set on the calliper gauge.

Illustr.: 4-38: Measure distance

Spindle elongation

Nut M8x1

Pulley

Fork wrench

SW 14

Pulley

Calliper gauge

Pulley

Lathe slide

Loading...

Loading...