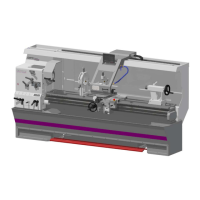

Do you have a question about the Optimum OPTiturn TM 4010 and is the answer not in the manual?

Identifies machine variants and key specifications.

Explains hazard classification, pictograms, and warning signs.

Defines proper application and outlines foreseeable misuses.

Details personnel requirements and operational safety precautions.

Covers electrical, motor, headstock, feeds, slides, tailstock, and support accessories.

Details coolant, work area, environmental conditions, and operating materials.

Provides overall machine dimensions and installation layout.

Procedures for unpacking and verifying delivered items.

Safety warnings and methods for moving the machine.

Criteria for selecting a suitable installation location.

Covers cleaning, lubrication, electrical connection, and initial startup.

Identifies and explains machine controls and indicators.

General safety precautions during machine operation.

Covers switching on/off, emergency stop, speed, and turning direction.

Details feed, thread cutting, tool holding, tailstock, and coolant.

Guidance on choosing appropriate cutting speeds.

Factors affecting the selection of cutting speed.

A practical example for calculating spindle speed.

Reference tables for cutting speeds based on material and tool.

Safety precautions specific to maintenance and repair tasks.

Schedule and procedures for regular checks and maintenance.

Specific maintenance for the lathe chuck.

Information on obtaining repair services.

Information required for ordering spare parts.

Reference to electrical parts and wiring diagrams.

Detailed exploded views and parts lists for various machine components.

Copyright, glossary, and change information.

Details on warranty terms and exclusions.

Storage, dismantling, disposal, and product follow-up information.

| Swing over bed | 400 mm |

|---|---|

| Center height | 200 mm |

| Distance between centers | 1000 mm |

| Max turning length | 940 mm |

| Bed width | 250 mm |

| Spindle bore | 52 mm |

| Spindle taper | MT5 |

| Spindle speed range | 40 - 2000 rpm |

| Number of spindle speeds | 12 |

| Tailstock quill taper | MT3 |

| Tailstock quill travel | 120 mm |

| Voltage | 400 V |