5 Installation

−17−

Maximum applicable plate thickness

Unit model

Maximum applicable

plate thickness

BLH230 5 mm (0.20 in.)

BLH450 8 mm (0.31 in.)

BLH5100 12 mm (0.47 in.)

∗ The figures in the table apply when the supplied hexagonal socket head screw is used.

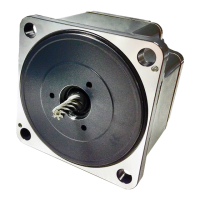

Changing the motor cable’s routing direction

The gearhead can be removed and the motor cable position changed to one of three

90° directions. Note that the motor cable cannot be positioned in the direction where

the cable faces the gearhead output shaft.

1. Remove the hexagonal socket head screws (4 pcs.) attaching the

gearhead and motor and detach the motor from the gearhead.

Hexagonal socket head

screws

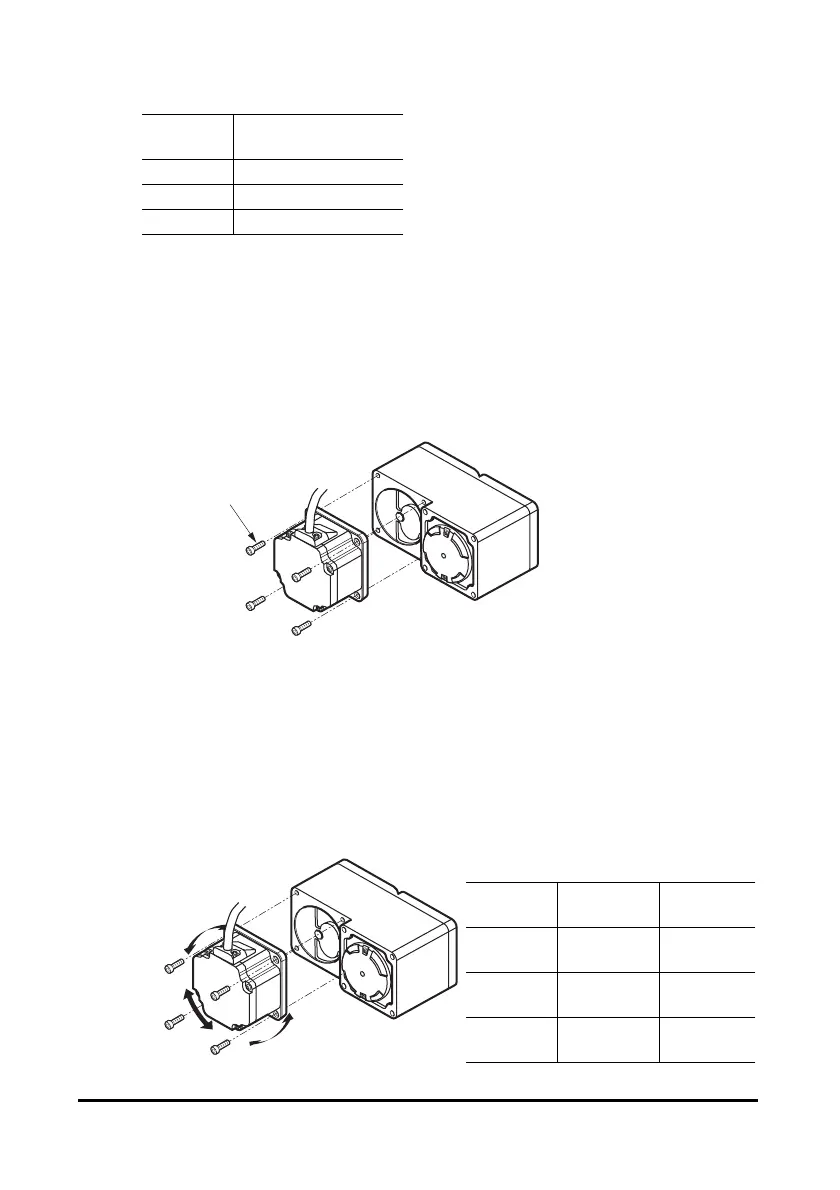

2. Using the pilot sections of the motor and gearhead as guides, install the

motor to the gearhead and tighten the hexagonal socket head screws.

At this time, the motor cable position can be changed to one of three 90°

directions.

When installing the gearhead, slowly rotate it clockwise/counterclockwise to

prevent the pinion of the motor output shaft from contacting the side panel or

gear of the gearhead.

Also, confirm that no gaps remain between the motor flange surface and the end

face of the gearhead’s pilot section.

Unit model

Nominal

thread size

Tightening

torque

BLH230 M4

1.8 N·m

(15.9 lb-in)

BLH450 M6

6.4 N·m

(56 lb-in)

BLH5100 M8

15.5 N·m

(137 lb-in)

Change the cable

position to a desired

90° direction.

Loading...

Loading...