5 Installation

−21−

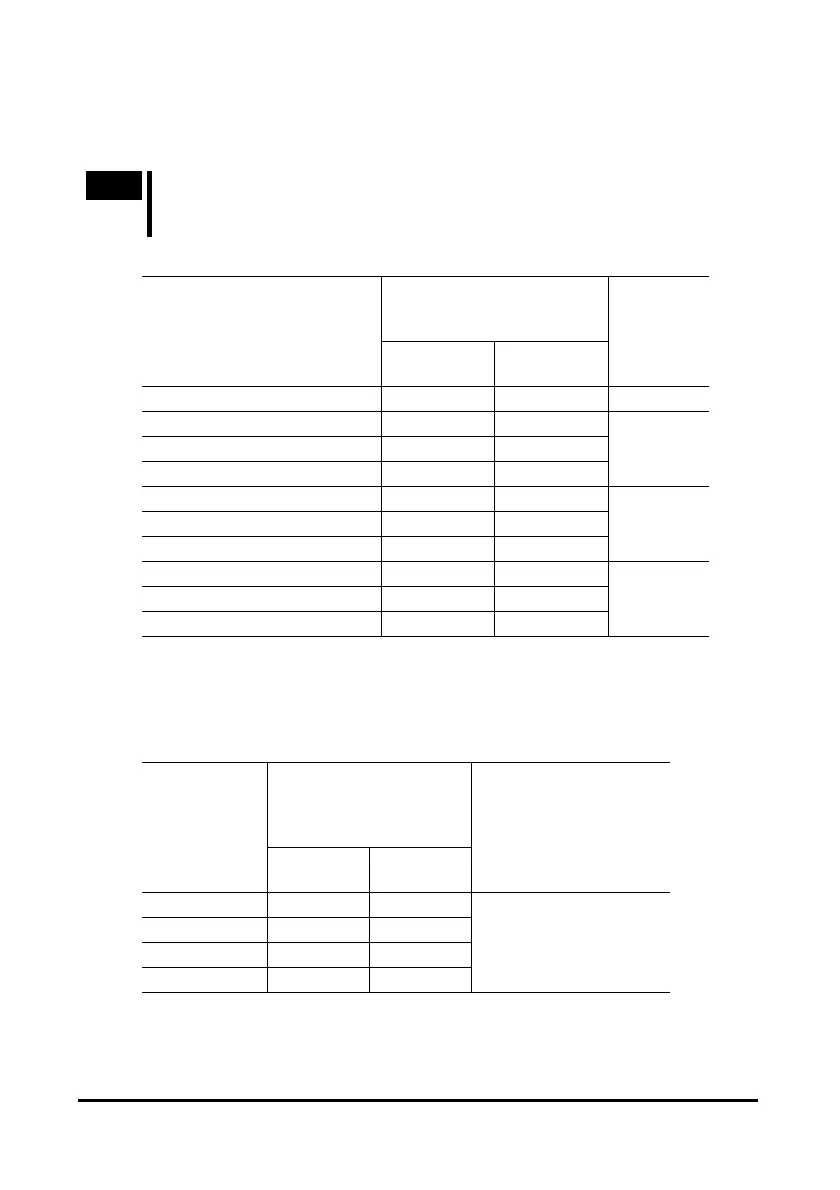

Permissible overhung load and permissible thrust load

Make sure the overhung load and thrust load received by the motor (gearhead)

output shaft will not exceed the allowable values shown in the table below.

Note

If the overhung load or thrust load exceeds the specified allowable value,

repeated load applications may cause the bearing or output shaft of the motor

(gearhead) to undergo a fatigue failure.

Geared type, combination type parallel shaft gearhead

Distance from tip of gearhead

output shaft and permissible

overhung load [N (lb.)]

Unit model

∗

10 mm

(0.39 in.)

20 mm

(0.79 in.)

Permissible

thrust load

[N (lb.)]

BLH015K- 50 (11.2) − 30 (6.7)

BLH230KC-5 100 (22) 150 (33)

BLH230KC-10, 15, 20 150 (33) 200 (45)

BLH230KC-30, 50, 100, 200 200 (45) 300 (67)

40 (9)

BLH450KC-5 200 (45) 250 (56)

BLH450KC-10, 15, 20 300 (67) 350 (78)

BLH450KC-30, 50, 100, 200 450 (101) 550 (123)

100 (22)

BLH5100KC-5 300 (67) 400 (90)

BLH5100KC-10, 15, 20 400 (90) 500 (112)

BLH5100KC-30, 50, 100, 200 500 (112) 650 (146)

150 (33)

in the model names indicates a number representing the gear ratio (5, 10, 15, 20,

30, 50, or 100).

∗ For the lead wire type, “KC” of the unit model is replaced by “K” (except for BLH015

type).

Round shaft type

Distance from tip of motor

output shaft and

permissible overhung load

[N (lb.)]

Unit model

∗2

10 mm

(0.39 in.)

20 mm

(0.79 in.)

Permissible thrust load

[N (lb.)]

BLH015K-A 50 (11.2) −

BLH230KC-A 70 (15.7) 100 (22)

BLH450KC-A 120 (27) 140 (31)

BLH5100KC-A 160 (36) 170 (38)

Not to exceed one-half

the motor’s dead weight

∗1

∗1 Minimize the thrust load. If a thrust load must be applied, do not let it exceed one-half the

motor’s dead weight.

∗2 For the lead wire type, “KC” of the unit model is replaced by “K” (except for BLH015

type).

Loading...

Loading...