34

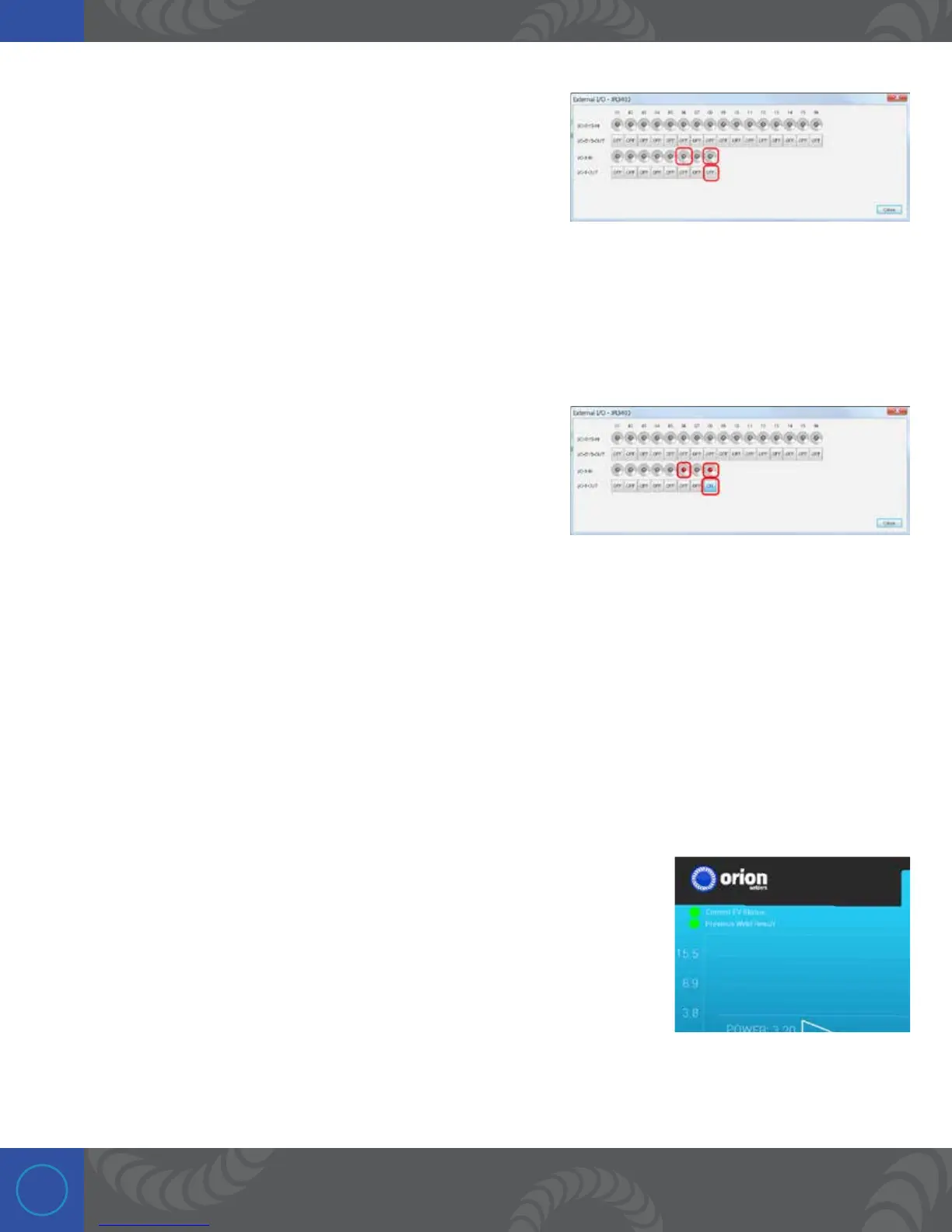

I/O-1-IN pin 06 is the Weld Ready signal. I/O-1-IN pin 08 is the

Weld Good signal. I/O-1-OUT pin 8 is a button that can be used

to trigger a weld. Both indicators are off, so this indicates that

the welder is not ready and the welder hasn’t welded yet, or that

the last weld was bad. When you first

get to this screen, I/O-1-IN pin 08 should be gray (OFF) and I/O-1-IN pin 06 should be red (ON). Once you

click on I/O-1-OUT pin 8 it will change the text from “OFF” to “ON.” Once the welder has triggered you will

need to click this again to change the text back to “OFF.”

During a weld, all the inputs will be gray (OFF) and the output will

be red (ON). Once you click the output button again, it will go gray

(OFF), which has to happen before the next weld. Both inputs,

Weld Ready and Weld Good should be red (ON) if the weld was

good and the welder is ready to

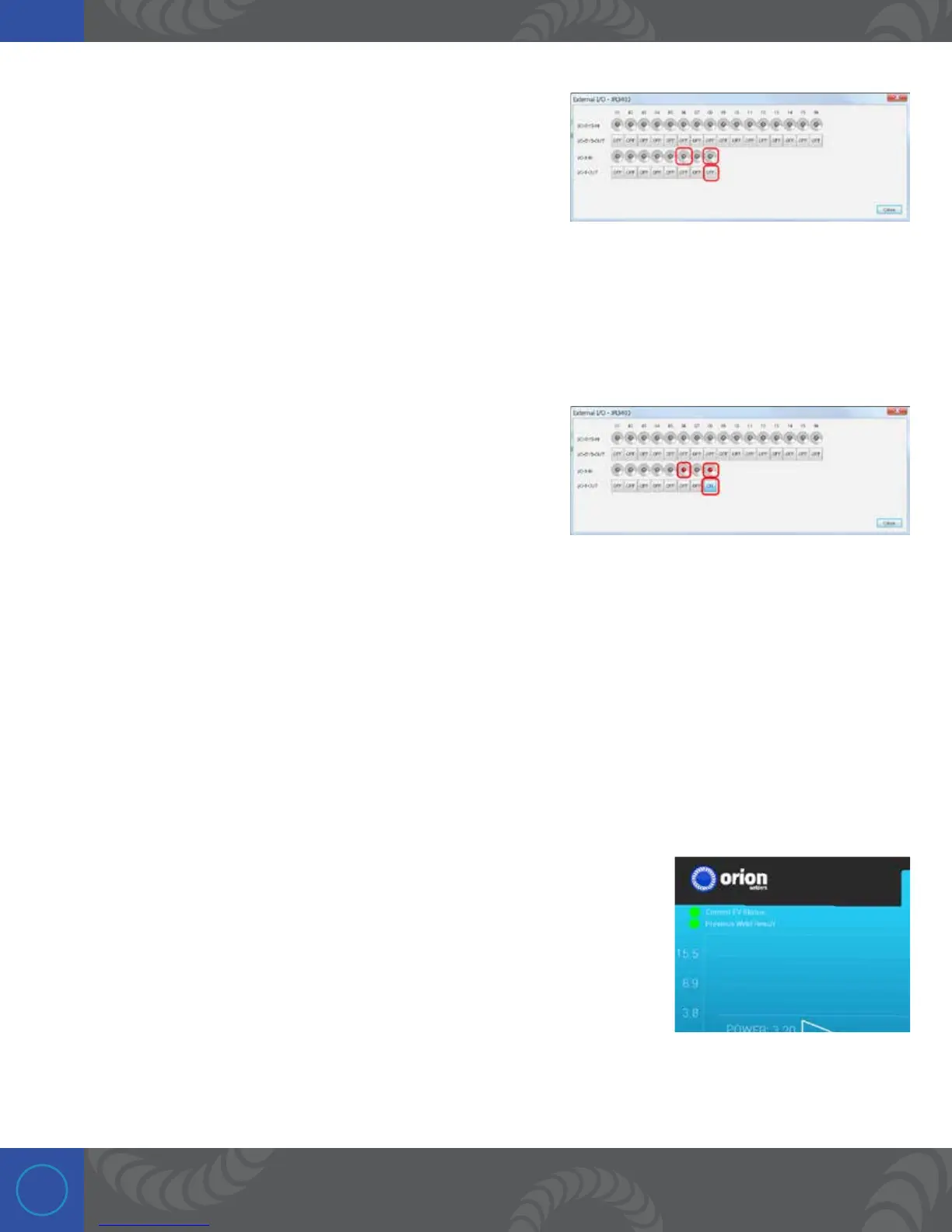

weld again. is will be what normally happens. If I/O-1-IN pin 08 is gray (OFF) after welding, then the

previous weld was bad. is could happen for various reasons:

• e weld head is not in position so a dry fire happened.

• e electrode is not in the collet of the nozzle cone.

• e electrode stuck to the surface.

• If this happens you will want to increase the lift off delay in the ignition settings screen on the Orion

250i2 screen.

• e electrode was too far from the surface, so you will want to decrease the lift off delay in the

ignition settings screen on the Orion 250i2 screen.

In the top left of the Orion 250i2 screen, the PLC Weld Ready and Weld Good

signals are displayed for your convenience. ese two dots will display the

same information we just looked at on the I/O Test screen on the pendant.

Green means ready and good weld and red means not ready and bad weld.

Loading...

Loading...