11

Operating Procedures

Pre-operation Procedures

Pre-operation Procedures

■Checking the Water Level

Confirm there is water in the water tank.

Add water to the water tank. The amount of water should be at least the amount of water shown in

the following chart.

RKS250F1-S RKS400F1

Required water tank volume (L)

10 20

IMPORTANT

●If the amount of water is lacking, it could result in a high on / off cycling of the compressor,

which could result in damage to the compressor.

●Consult with a qualified specialist if the water tank capacity is too low or regarding

construction of an automatic water supply.

■Priming the Pump

1. Confirm that there is no dirt or other material

clogging the strainer assembly on the water intake

side of the water piping.

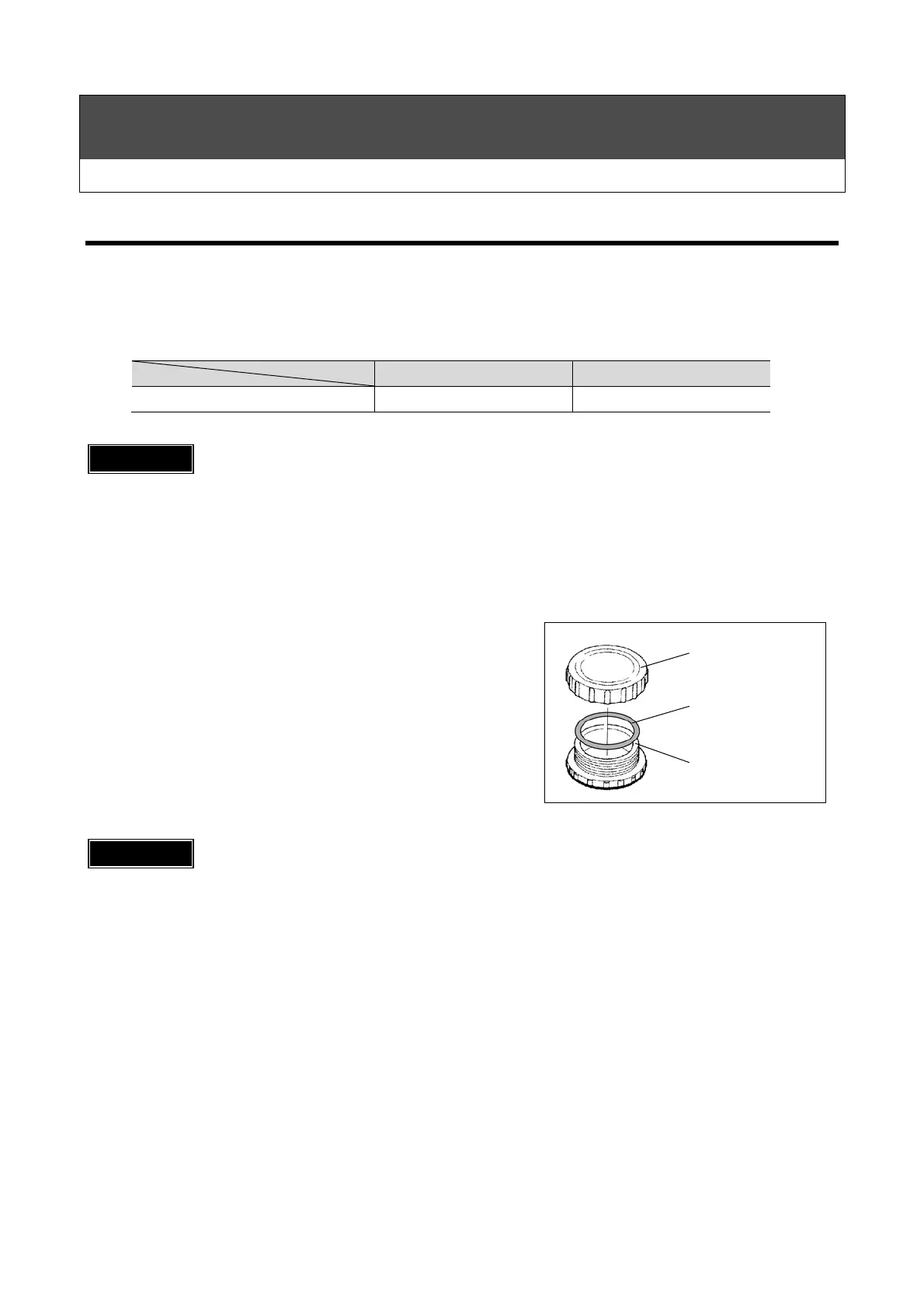

2. Wet the pump-priming port gasket with water

beforehand to make it slippery.

3. Slowly add water from the pump-priming port until

the water intake piping and pump are filled.

4. After filling, be sure to hand-tighten the

pump-priming port cap.

IMPORTANT

●Failure to prime the pump will cause the pump to run dry, preventing water from being chilled,

and it will also result in damage to the pump.

● Because of the strainer assembly, priming the pump is not required other than when the

product is operated the first time. However, the pump will need to be primed again, as was

done initially, after the water has been drained, after the pipes have been cleaned, or air

entering the water circuit.

● Priming water only needs to be added so that the water intake piping and pump are filled. Be

careful not to add water too vigorously or all at once. Doing so can cause a siphon effect to

occur, causing the water to be drawn out of the water outlet port, and preventing the water

from collecting where it is needed for priming.

● Do not loosen the priming water cap while the product is operating. Loosening the cap could

allow air to enter the pump, resulting breakdown due to running dry.

Pump-priming

ort ca

Pump-priming

port gasket

Pump-priming

port

Loading...

Loading...