OSAKA - F 200 / F 300 / TSF 200 / TSF 300 / M3 - User Manual - V.2 - PAG. 3

parameters needed, without access to all parameters that are

specific of technical or machine manufacturer.

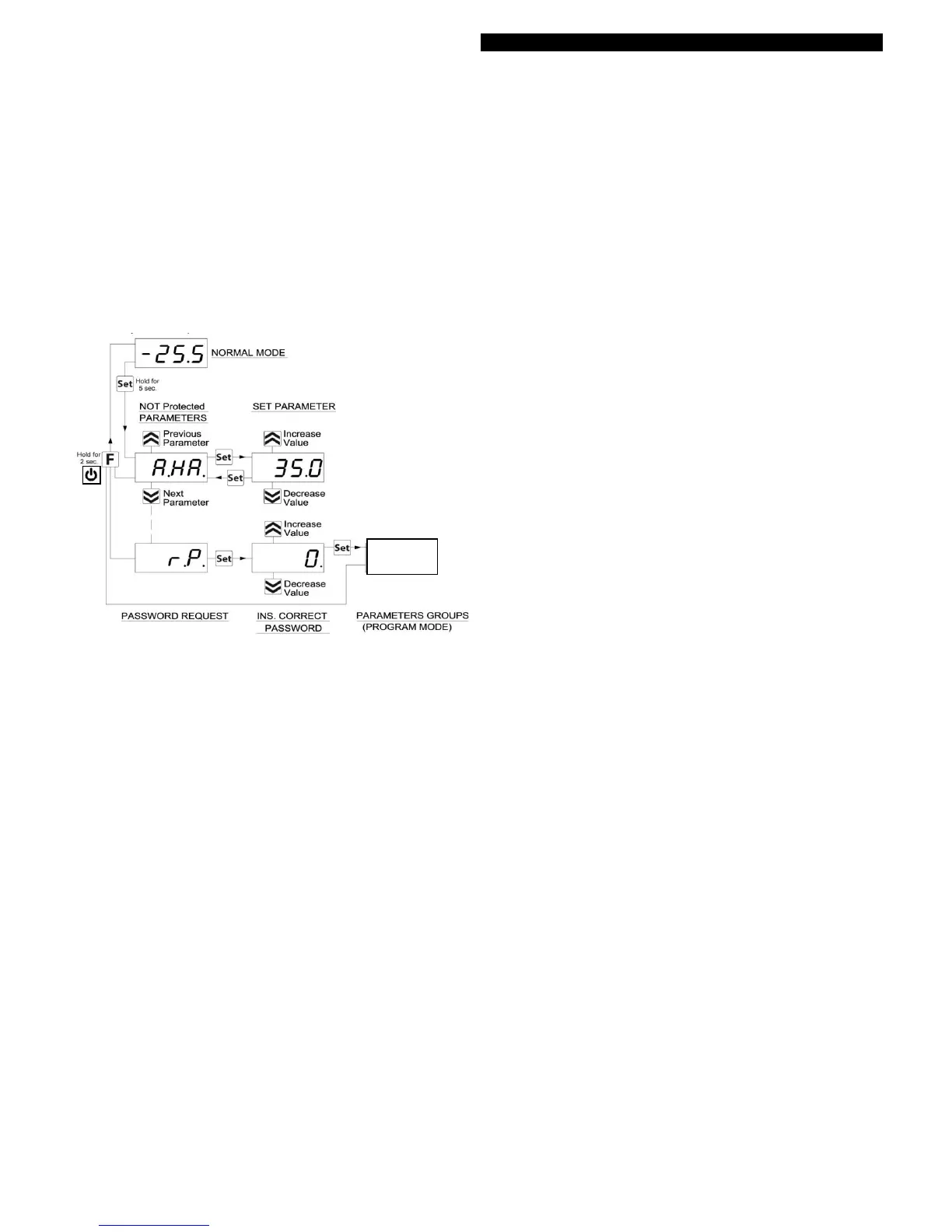

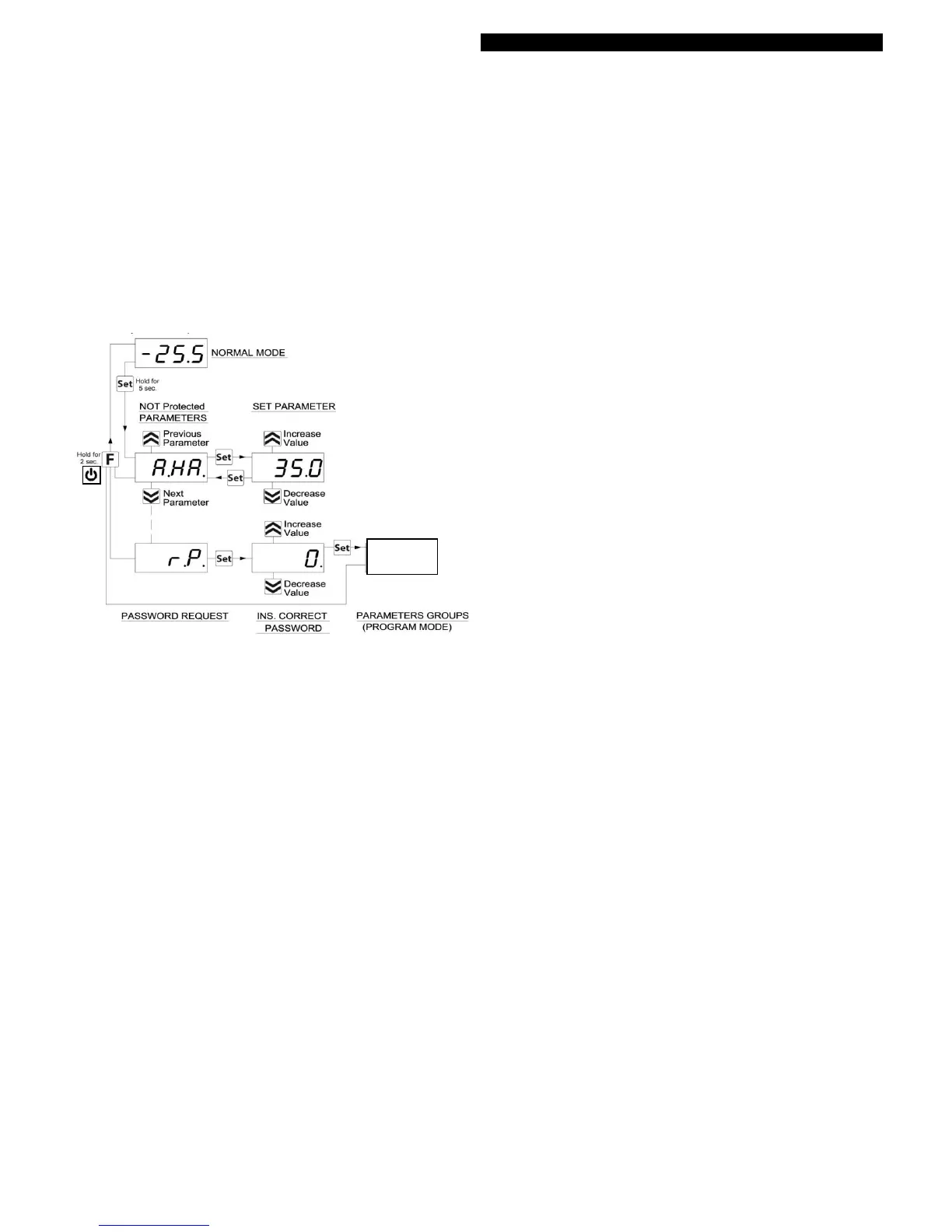

Method to select the level of programming parameters:

Access programming through password and select the parameter

to be programmed without password. If the SET LED flashes

means that the parameter is programmable only with password

protected, and if the LED is fixed indicates that the parameter is

direct access without password.

To modify the visibility level parameter jointly press "Set + Up"

keys.

The LED Set will change status, indicating the new access level

parameter (protected, flashing led) and (direct access without

password, fixed led).

Upon entering the menu, the first parameters to visualize are user

level parameters (unprotected) and then (protected) by entering the

password when the computer shows "rP"

2.5 – RESTORE FACTORY SETUP PARAMETERS

The device has a mode parameter reset to factory programmed

values.

To return to the factory settings or default values of the parameters

is sufficient to activate the password protection and once activated

when the display set "rP" enter the password -48.

After confirming the password with the SET button for 2 seconds

display will show "---" when the computer performs the reset of the

parameters, does a little testing and put all settings to default

values.

2.6 - KEYBOARD LOCK FUNCTION

It is possible to completely lock the keys. Such a function is useful

when the control is accessible to the public and you want to prevent

tampering. The key lock function is activated by setting the "t.Lo"

parameter to a value of OF.

The value set in parameter "T.Lo" is the time that the thermostat

allows access to the keyboard and after passing this time the

thermostat is locked.

Pressing any key displays the thermostat "Ln" to inform the lock is

activated.

To unlock the keyboard press "Set + Up" for 5 sec., the display will

show "LF" and all keyboard functions again become operational.

3.1 – PROPER USE

The devices are made as measuring and regulating equipment in

accordance with EN EN60730-1 norm for operation up to an

altitude of 2000 mts.

The use of equipment for standard applications not expressly

provided in norm cited above, should provide all measurement and

adjustments necessary protection.

The equipment must be adequately protected and away from

liquids, dust, grease and dirt. They must be accessible only with the

use of a right tool and safety system (except the front).

The devices can NOT be used in dangerous environments

(flammable or explosive) without adequate protection.

It is recalled that the installer must ensure that the norm for

electromagnetic compatibility is respected after implantation in the

installation of equipment, eventually using the right filters if is

needed.

In case of failure or malfunction of measuring and control

equipment that can create dangerous situations or damage to

persons, things, animals or products (defrost food or changes in

their ideal state), it is recalled that the facility should be equipped

with electronic devices or electromechanical safety and warning

system.

They should be placed outside the measuring and control

equipments, possible protective devices, responding to specific

safety requirements that are covered by the norm of the product or

suggest the common sense.

For your own safety, is highly recommended fulfilling the

instructions provided above.

3.2 – MECHANICAL ASSEMBLY

The thermostats are designed for wall mounting or wall using the

holes in the plastic and predisposed accessible after removing the

front.

Once the equipment is installed is recommended to close the front

cover.

Avoid placing the thermostat in place exposed to high humidity or

dust, this can cause condensation or introduction of conductive

particles or substances. Ensure that the computer has adequate

ventilation and avoid installing indoor sealed boxes or areas where

the temperature exceeds the specifications of the device. Avoid

installing the cables and power supply together with the probe out

and install equipment that can generate disturbances (electrical

noise) as motors, fans, inverters, automatic gates, contactors,

relays, solenoids, etc.…

3.3 – ELECTRICAL CONNECTIONS

The thermostat is designed for permanent connection between

devices, no switch is equipped with internal devices or power on

over currents or voltages. It is therefore recommended to install a

general safety thermal / isolator switch / device magneto device as

close and easy access to cut if necessary, as a security . Are

reminded that you must use appropriate cable to own isolation

voltage, current, temperature and local electrical codes should also

separate the signal cables from the power probe and power as far

as possible in order avoid possible electrical noise, electromagnetic

induction, which in some cases could be diminished or cancelled

with RC filters, ferritic, supply, varistors, etc. ... the use of cables

with antiparasitic mesh and this mesh is recommended to connect

on one side to take ground.

It is recommended to check that the equipment settings are

appropriate to the application before connecting wires actuators,

loads on the output relays in order to prevent malfunctions or

damage.

Loading...

Loading...