OSAKA - F 200 / F 300 / TSF 200 / TSF 300 / M3 - User Manual - V.2 - PAG. 7

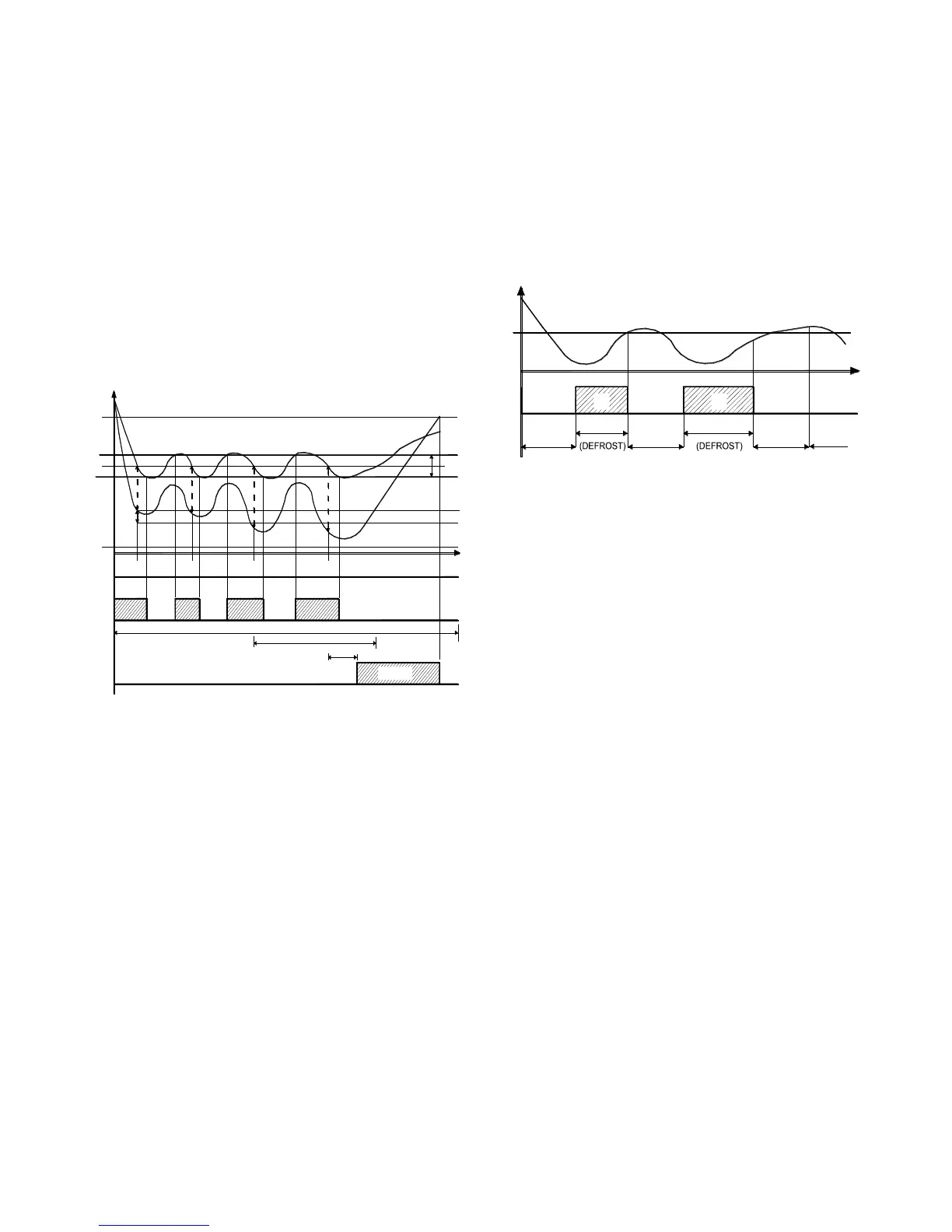

= ct – At time intervals of working compressor. Adding the partial

operation times every X hours working will perform a defrost. This

mode is used only in facilities positive temperature cold.

= cS – (atypical special regulation) to each compressor stop.

Programming ("D.Di" = oF, defrosting is done only on stop the

compressor).

= St – Defrost evaporator temperature. The device activated a

defrost cycle when the evaporator temperature (probe set to EP)

amounts below the value set in the parameter. "D.tS" or the end of

time programmed in rt mode (if "D.Di" = oF defrost always done by

evaporator temperature) This system can be used to defrost the

evaporator used machinery such as pumps heat (in this case

defrosting time intervals would be disabled) to ensure defrost if the

evaporator temperature reaches well below that normally results

symptoms of low thermal change from the normal operating

conditions.

= dd – DYNAMIC REDUCTION DEFROST

This parameter is used in the so-called "Dynamic Defrost" in which

the device reduces the time between defrosts if system conditions

require.

By parameter "d.dd" = 0 .. 100% (recommended 25% to 50%

values) program "%" to be reduced if the system requires cutting

the time between defrosts.

P r1

T e m p.

tim e

EP

SP

r.d

o ff

ON

C oo l

(o t)

S P+ r.d

D T0

D T1

1 °

D T2

D T3

ON ON ON

o ff o ff

d .tE

d .d i / d .S d

D efro s t

(d F )

P h a se

0 1 2 3

tim e to d efro st P h . 0 , 1

tim e to d efro st P h . 2

tim e to d efro st P h . 3

D efro s t

d .tS

Operation Example "dynamic defrost system intervals" with

reduction "d.dd" = 30% and end defrost temperature.

The system anticipates the accumulation of ice leaving the battery

in peak condition. This function operates when the output of cold is

turned on and the temperature of the camera is in the Set Point +

rd / 2, if the difference between the temperature of the chamber

and the evaporator exceeds the reference value DT0 by 1 ° C or

more, and the difference between the evaporator and chamber is

superior to the last comparison, reduces the "d.dd" programmed

value on time "d.di" or "d.Sd". To use this system it is

recommended that the "d.di" parameter enter the longest possible

time taking into account the proper functioning of the system. The

advantage of defrosting at intervals is that it allows dynamic

scheduling intervals longer than normal and defrost work so they

are system conditions that determine whether the anticipated

implementation defrost if necessary.

If the set time is too short you may not have time to act "Dynamic

Defrost".

If the system is configured correctly, you manage to avoid many

UNNECESSARY defrost and as a result ... Energy Saving and

Efficiency.

4.8.2 – MANUAL DEFROST

To activate a manual defrost cycle press the UP / DEFROST key

while the device is in operation and hold down for 5 seconds. If

conditions are optimal for defrosting will be conducted, either

evaporator probe par. "D.te" and "d.ts".

To cancel a defrost proceed to press UP / DEFROST button for 5

seconds.

The activation commands / stop of a defrost cycle can also be via

the digital input.

4.8.3 – END OF DEFROST

The defrost cycle can be time consuming if the evaporator probe

(probe set to EP) is used to achieve the temperature.

In case that it can not use the evaporator temperature, the cycle

time will be established by the par. "D.dE".

If the evaporator temperature is used, the end of defrosting is when

the temperature measured by this probe set to EP exceeds the

temperature set by the torque. "D.tE".

If this temperature is not reached within the time fixed by the par.

"D.dE" defrost does not terminate.

So if the temperature measured by the evaporator probe is higher

than that imposed in par. "D.tE" defrosting is inhibited.

The defrost cycle is indicated by the led DEF. At the end of defrost

to delay the restart of the compressor (output "ot") time set in par.

"D.td" to allow the evaporator drip.

During this delay, the LED blinks to indicate DEF status finish drip.

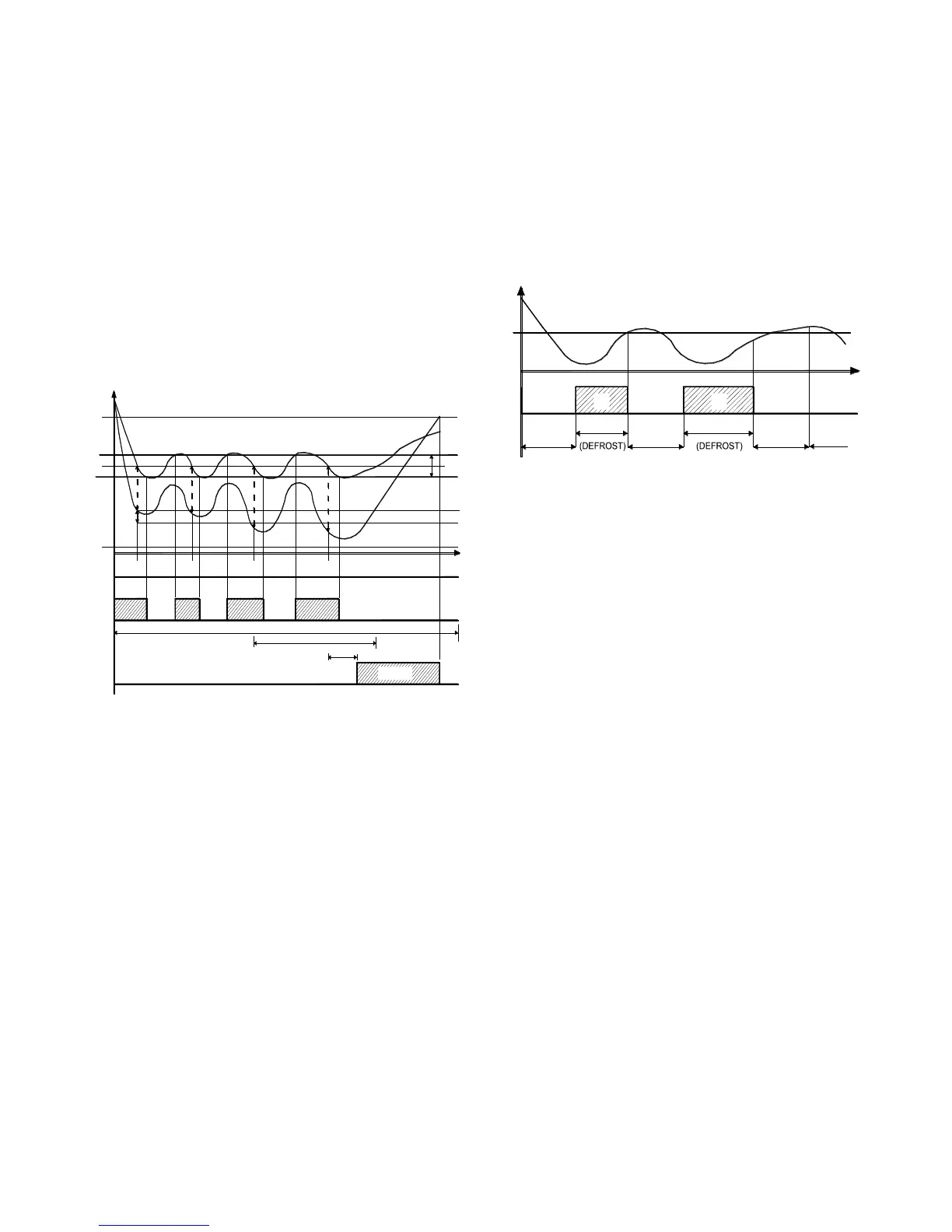

d .d i

T e m p .

dF

d .d i/d .S d

o ff

d .tE

ON

A

o ff

EP

d .d i

ON

d .d E

B

(N O d e fro st)

d .d i

o ff

C

tim e

Example of end of defrost: Defrost indicated as "A" ends up

reaching the temperature "d.tE", the "B" part ends at the end of

"d.dE" in terms of tempera "d.tE" is reached, the defrost "C" does

not work when the temperature is above "d.tE".

4.8.4 - DISPLAY LOCK ON DEFROST MODE

Using parameters "d.dL" and "A.Da" display behavior is

established during defrosting.

The "d.dL" parameter causes blocking last temperature on the

display before defrost ("d.dL" = on) until you reach the end of

defrost and the temperature does not exceed below the value of the

final temperature memorized or the condition ["SP" + "r.d"], or

exceeds the safety time lock "A.Da".

Also allows visualization of the indicative initials Defrost "dEF" ("dl"

= Lb) and after defrost the acronym "PdF" that indicates time

defrost finish but cold temperature not recovered to control value

["SP" + "r.d"]) or exceeds the safety time lock "A.Da".

Another possibility is to indicate the actual temperature of the cold

chamber or cabinet, during defrosting ("d.dL" = oF).

4.9 - EVAPORATOR FAN CONTROL

The evaporator fan control works for output configured as "Fn"

function in certain states of the device and the temperature

measured by the evaporator probe (probe set to "EP").

The parameters related to the fan control functions are in the " Fn"

folder.

In the event that the evaporator probe is not used or is in error, the

output configured as "Fn" is activated only in function of the

parameters "F.tn", "F.tF" and "F.FE".

Using parameters "F.tn" and "F.tF" you can set the behavior of the

evaporator fan when the control output configured as "ot"

(compressor) is switched off.

When the output "ot" is off may cause the output configured as

"Fn" continue to operate cyclically according to the times

programmed in the "Ftn" parameter (activation time fan evaporator

compressor off) and "F.tF" (time deactivation evaporator

compressor off) fan. By stopping the compressor equipment

evaporator fan can keep ignition time "F.tn", and disable the time

"F.tF" when output "ot" remains disabled. Programming "F.tn" Fn =

oF the output is turned off by stopping the output "ot" (evaporator

fan off stopped functioning compressor or fan attached to the

compressor).

Programming "F.tn" to any value and "F.tF" = oF the "Fn" output

will remain active also disabling the output ot (active compressor off

evaporator fan).

Loading...

Loading...