6 of 27 7 of 27

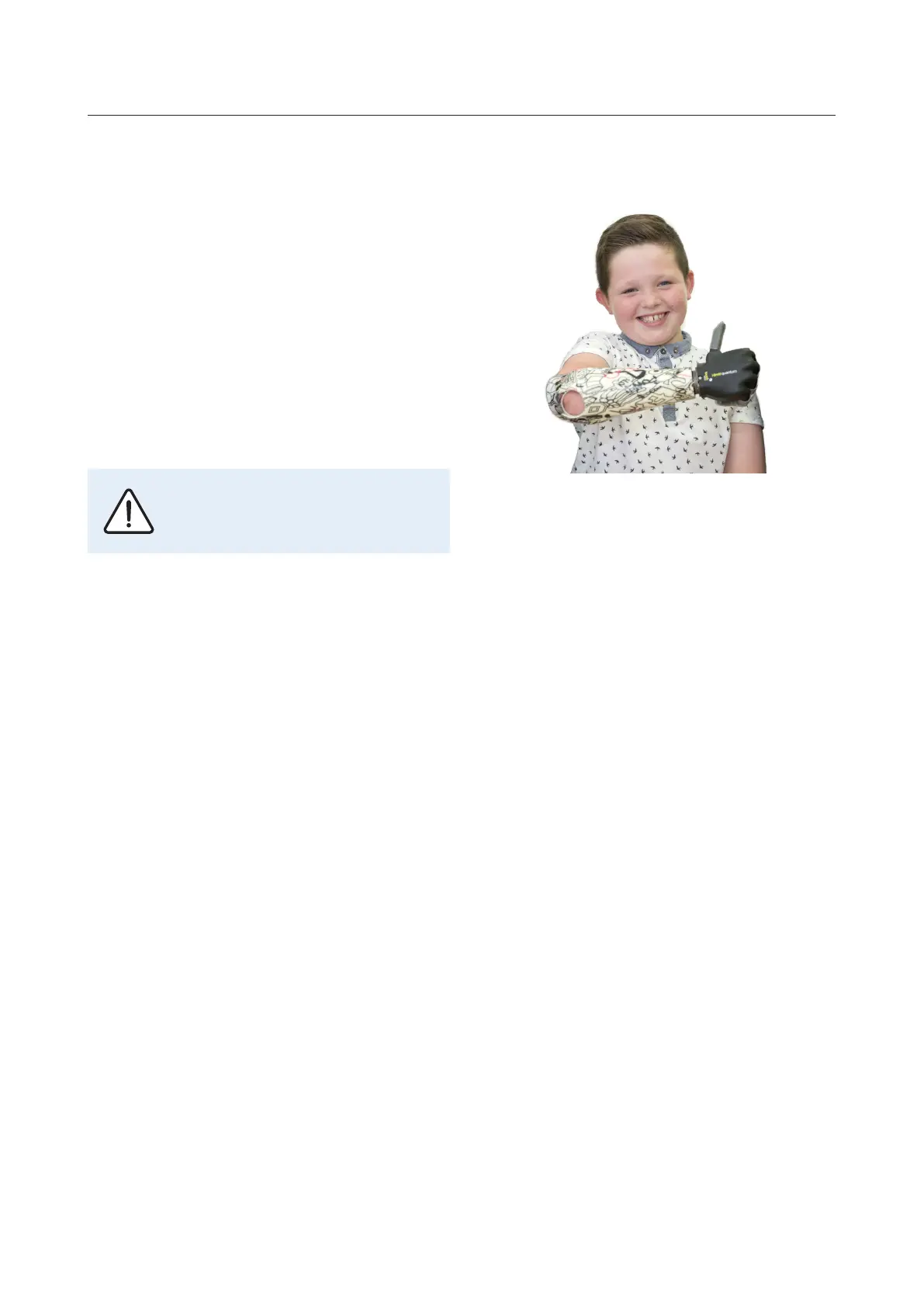

2.0 Prosthesis fabrication

The i-limb hand is assembled in combination with a

socket made to the requirements of the individual user.

When fabricating the prosthesis for the i-limb

®

hand

consideration should be given to:

a. Electrode positioning

b. Battery placement, size and configuration

c. Charge port placement

d. Socket length and overall length of the prosthesis

Precautions should be taken against sweat entering the

components, as sweat ingress can cause damage and

compromise the function of the prosthesis.

The use of carbon fiber is not recom-

mended due to electrical conductivity.

2.1 Socket materials

The socket design and materials used for the prosthesis

are based on the clients presentation and skin condition.

Typical inner socket materials include silicone, thermo-

plastic and laminate. The outer socket is primarily lami-

nate.

For a standard prosthesis, a minimum expected layup

would be;

Inner socket: 2 layers of perlon stockinette, 2 layers of

nyglass and 2 layers of perlon stockinette.

Outer socket: 4 layers of nyglass and 2 layers of perlon

stockinette.

The build of each prosthesis should be adjusted specifi-

cally to meet the individuals requirements.

It is not recommended to use carbon fiber within a myo-

electric prosthesis.

Loading...

Loading...