Section 5

LABELING UNIT

- 9 -

English

F412050100.fmIDM

version

Module 40/60/90/120

Foreword

The machine can be adjusted in several different

configurations, including the following changes and/or

adjustments:

– height of label positioning on the bottle;

– height of reel carrier disks and winding device disk;

– rings of the deviation rollers;

– position of the brake;

– position of the Stop photocell;

– angle of incidence of the label detaching blade

(label detaching device);

– label ejection speed (see page 15).

Important

Refer to the sizing parameter tables for the

settings relating to the various adjustments to

make. No tools are needed to adjust the SIZE. The

parts on which action has to be taken (knobs,

handles, rings) to change the size are colored in

red.

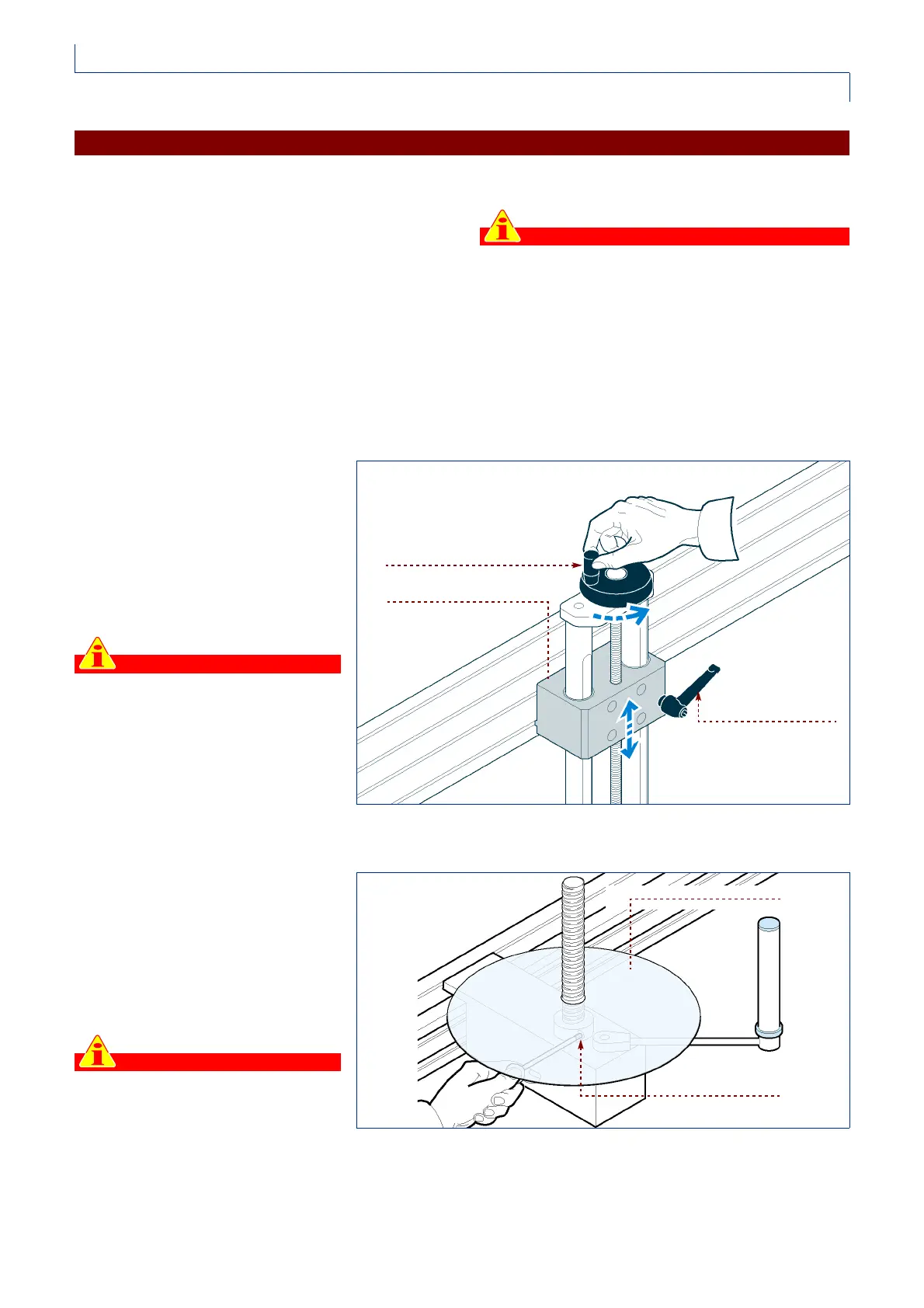

LABELLING MACHINE HEIGHT ADJUSTMENT

The height of the whole module can be

adjusted according to the height of

labelling required on the bottle.

1 -Loosen the handle.

2 -Turn the hand wheel to raise or

lower the column.

3 -Tighten the handle.

Important

If the 5-axis column is installed, it

may be necessary to take action on

the rolling, pitching and depth

adjustments too, according to the

values given in the size tables.

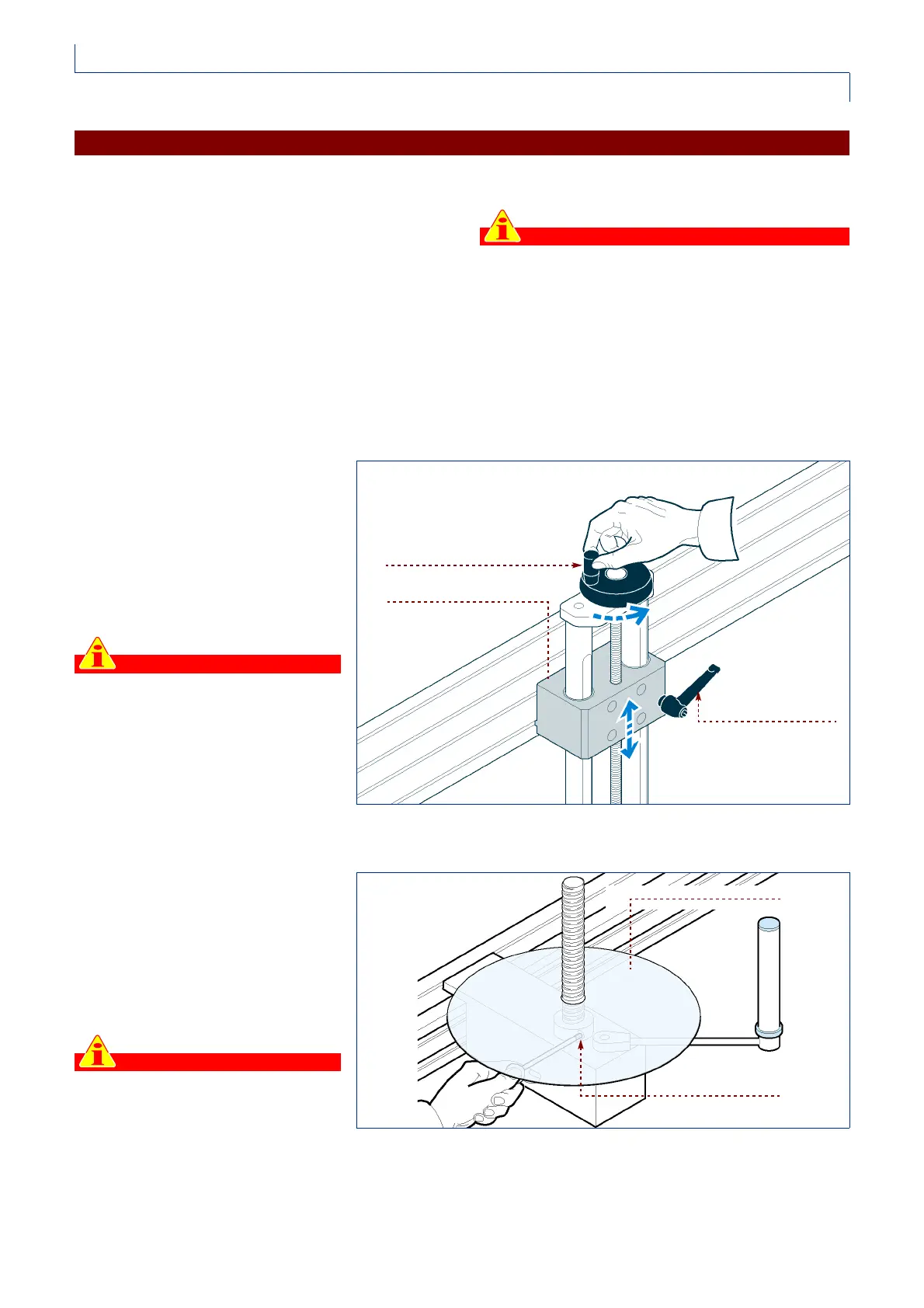

REEL CARRIER DISKS ADJUSTMENT

The height of the reel carrier disk can

be adjusted.

1 -Loosen the locking screw.

2 -Rotate the disk so that it can be

raised or lowered according to

operational needs.

Adjust both reel carrier disks

accordingly.

Important

Make sure that the reel carrier disks

on the unwinding device and winder

are on the same level (30 or 38 mm

from the top surface of the 80x80

support tubing). Adjust the red paper-guiding rings

fitted on the diverter rollers to the same level too. The

upper and lower rings must just come into contact

with the paper. Faulty alignment gives rise to:

- an inaccurate vertical positioning of the label;

- damage to the edge of the label backing paper;

- an untidy rewinding of the paper on the winder’s

spool.

ADJUSTMENT INSTRUCTIONS

IDM-41200600400.tif

hand-wheel

support

handle

IDM-01_008_0.tif

locking screw

reel carrier disk

Loading...

Loading...