37

11.1. Preventive Maintenance

Periodical maintenance is recommended to keep the drive unit in reliable working condition.

Wearing of moving parts can be monitored through the elapsed run time counter in the PLC. Run

time information is accessible for viewing on the touch screen through the setup menu.

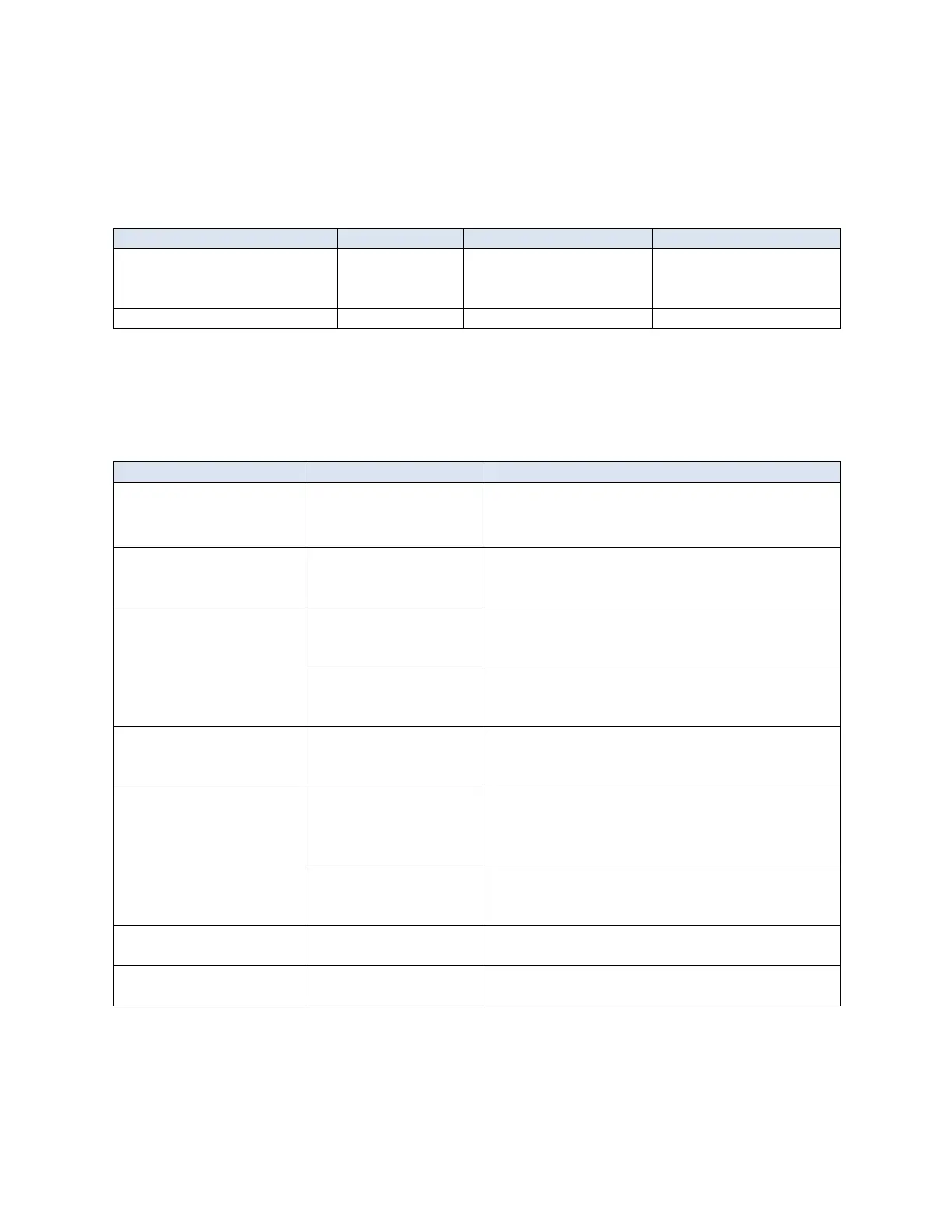

Recommended preventive maintenance procedures are listed in Table 8.

Table 8: Preventive maintenance procedures

Filter inspection. Replace if

deposits on the filter media

system run

tissue LT-SVSP327

procedure description

11.2. Troubleshooting

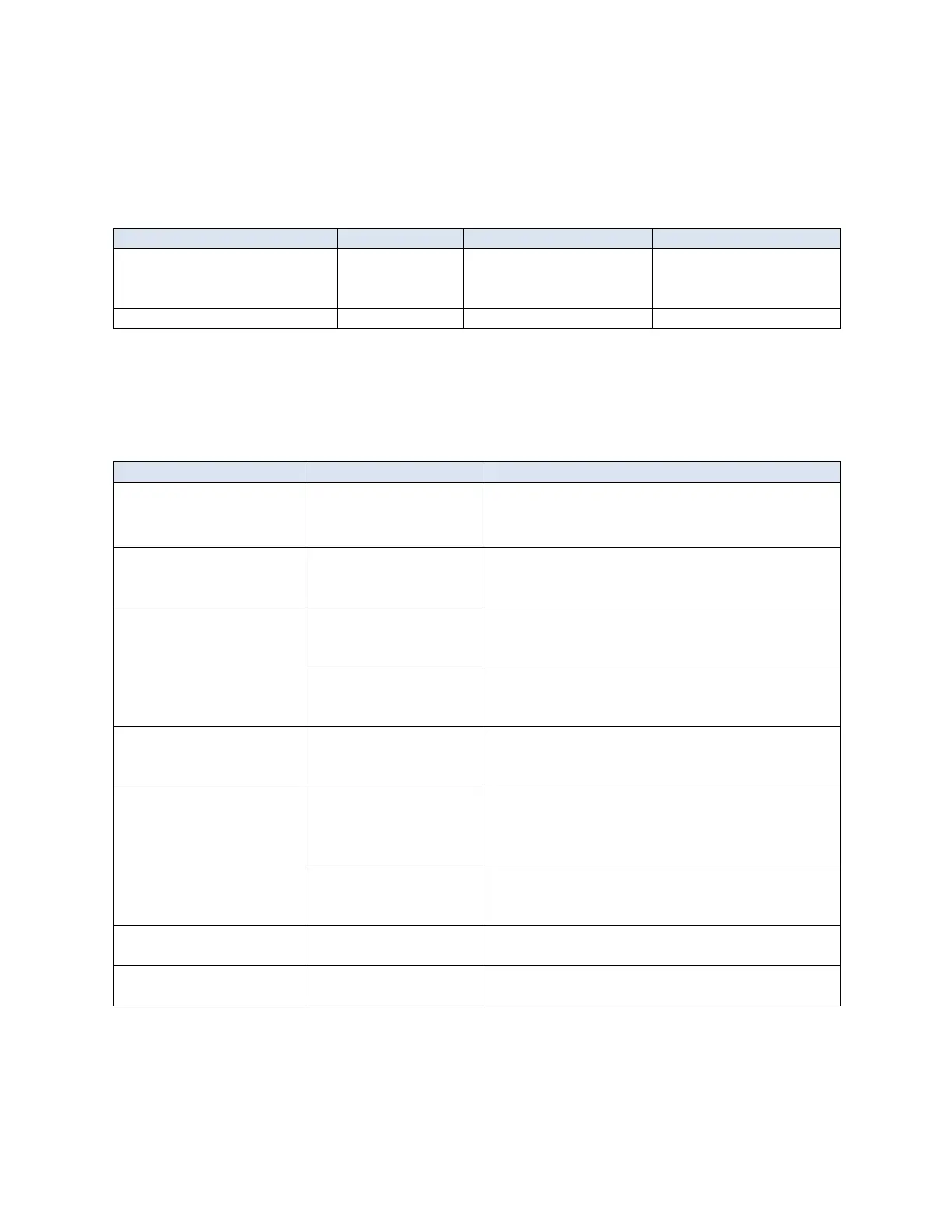

Table 9 lists ways for resolving possible problems. Contact technical service if problem persists.

Table 9: Troubleshooting

when power button is

pressed.

burned out

Replace the fuse. Follow procedure

description in this manual.

power is on while unit

burned out

Replace the bulb. Follow procedure

description in this manual.

rotation with jumps or

jerks with irregular

rattling sound.

overloaded with

Inspect impeller load in application, reduce

load if possible

Check if connection to tank made correctly

without tilt and/or air gap between drive

onscreen

Elevated risk of memory corruption and

unreliable operation. Call for technical

controller by frequent

starting-stopping of

Reset the motor controller alarm. Pause

about 3 min before starting up motor. Avoid

frequent starting-stopping of the motor.

damage of motor or

Contact service personnel

Cannot read/write to

micro SD card.

Micro card

improperly formatted

E-stop ALARM

persists after reset

E-stop button is

activated

Deactivate E-stop button by pulling it up until

it clicks, then reset the alarm.

Loading...

Loading...