44

Cleaning and Decontamination 11.3.7.

The steel frame of the machine consists of 304 stainless steel and may be cleaned with water

and isopropyl alcohol.

NOTE: It is important to ensure the system is turned off before cleaning the device.

Speed Calibration Verification 11.3.8.

Equipment recommended:

• Test impeller: Accessory item 4100655 equipped with piece of reflective tape (tachometer

accessory) on side surface.

• Optical tachometer: Omega HHT13 or equivalent

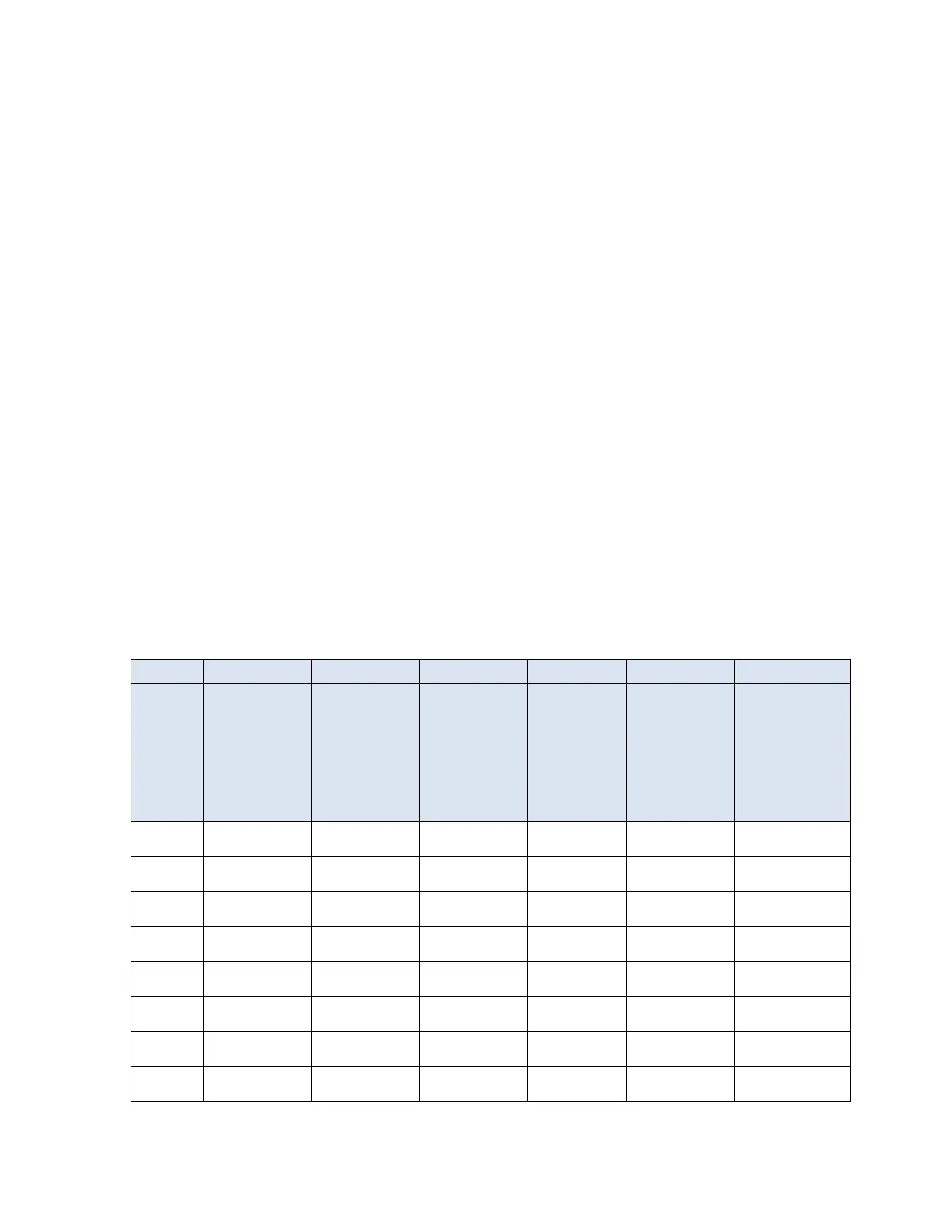

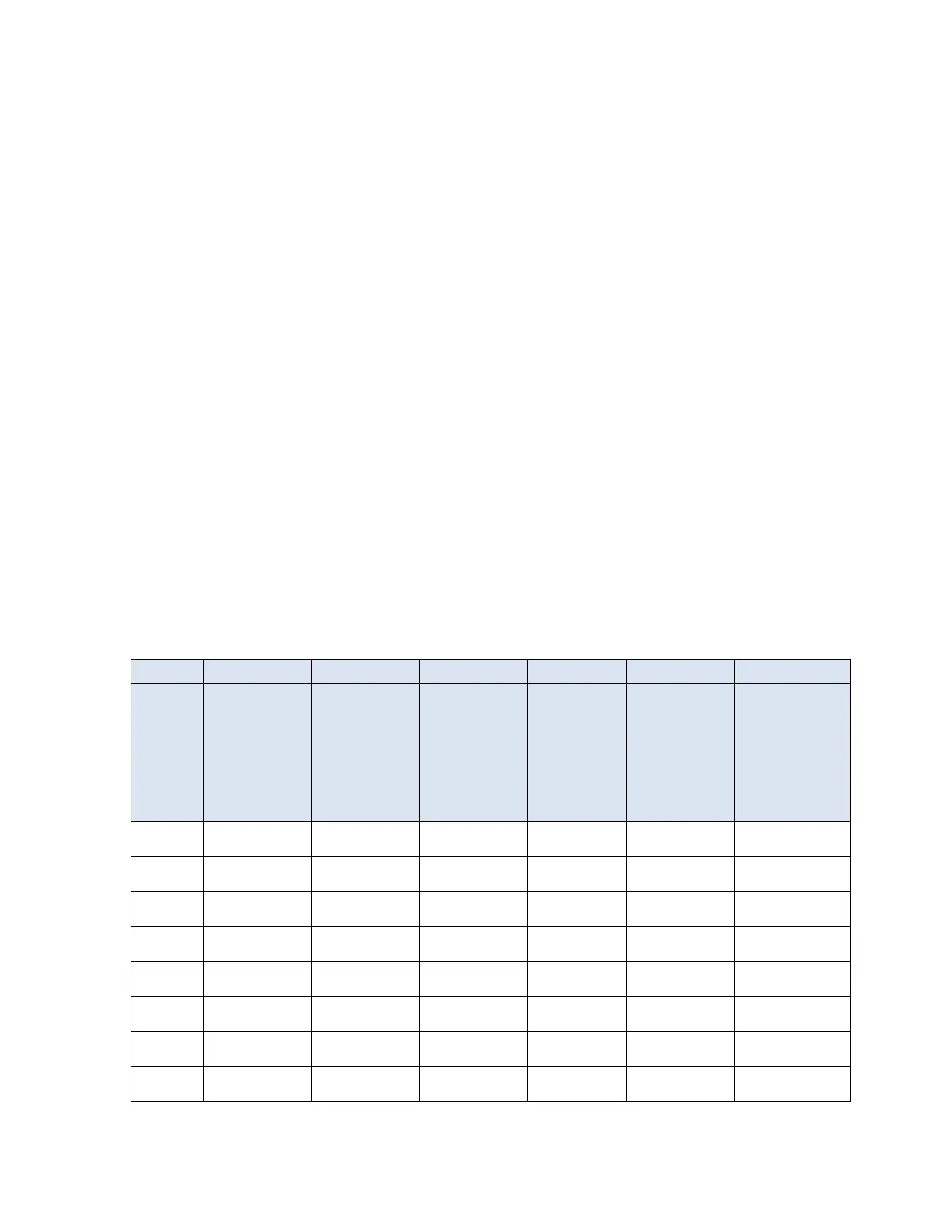

The drive unit should be set to manual mode of operation. Use Table 10 to document the

calibration.

1. Set the permanent run speed of rotation to 20 RPM.

2. Press and hold the ‘start’ button, rotation started. Wait until the impeller accelerates to its

nominal speed of rotation.

3. Reading from external tachometer, write into the second column of the table.

4. Calculate the difference between set point and the value measured in 3.

5. Compare the reading recorded in column 2 with corresponding allowable range in the

third column, and then record the result in column 6.

6. RPM Reading from panel screen record into the fourth column.

7. Compare the reading recorded in column 4 with corresponding allowable range in column

5 of the table, and then record the result in column 7.

8. Repeat steps 3 to 7 for each of the RPM set points in the first column.

9. If unsuccessful, call service.

Table 10: Rotational speed calibration test measurements

Point

(RPM)

Tachometer

Reading

(RPM)

Tachometer

reading

allowable

range

(RPM)

Tachometer

Reading

(RPM)

reading

allowable

range

(RPM)

Tachometer

Max

Deviation

falls within

allowable

Tachometer

Max

Deviation

falls within

allowable

20

60

100

140

180

220

260

300

Loading...

Loading...