18

3.2 Operating Pressures, Temperatures and pH

Operating limit specifications for pressure, temperature, and pH are listed in Table 4.

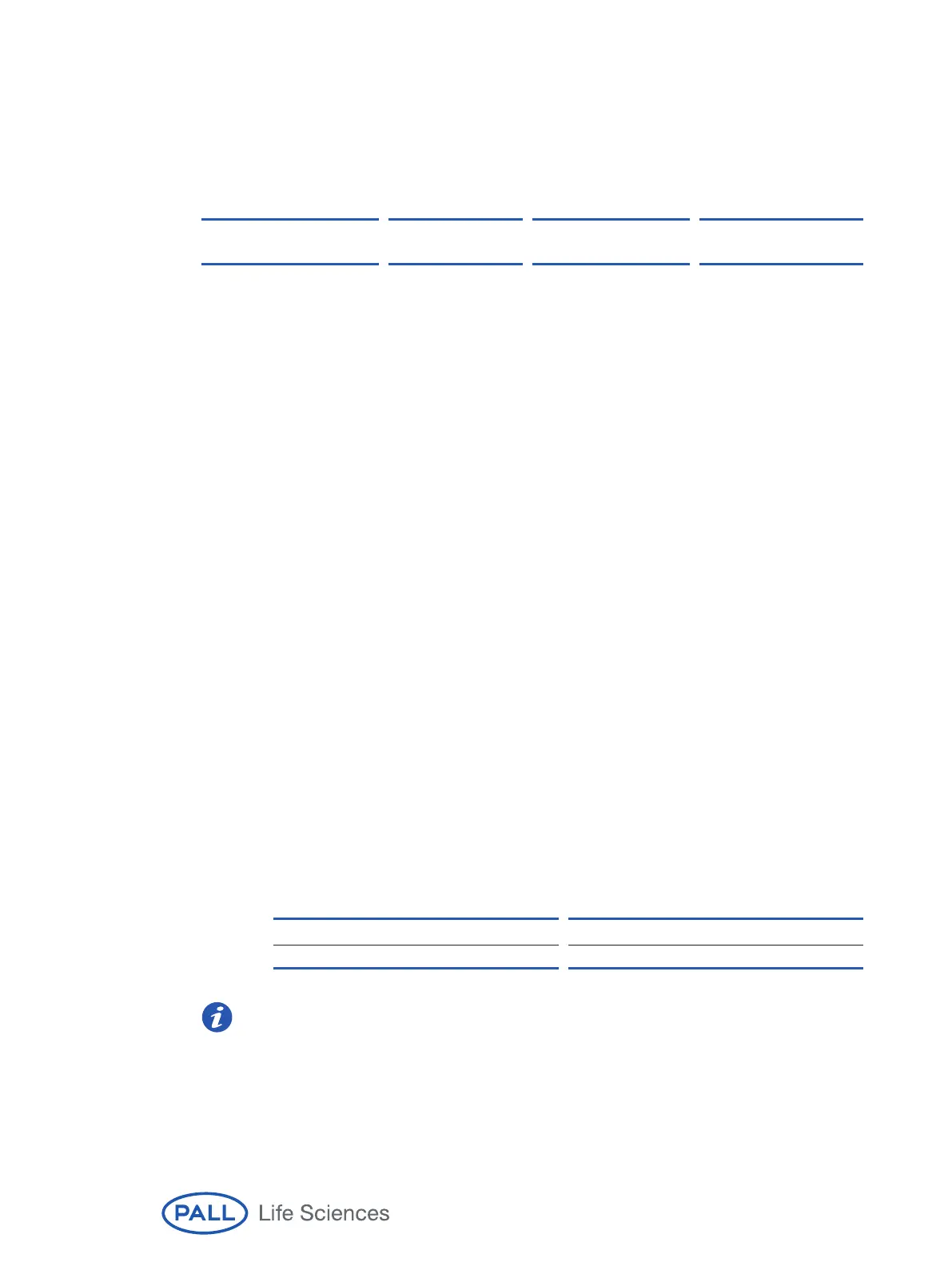

Table 4

Cassette Operating Limits of Pressure, Temperature, and pH for T-Series Cassettes with Omega

Membrane (All Formats)

Maximum Recommended

Operating Pressure

**

Maximum TMP Temperature Range pH Range

6 barg (87 psig) @ 23 °C 4 barg (58 psig) -5 to 55 °C 2 to 14 @ 4 barg (58 psig)

4 barg (58 psig) @ 55 °C @ 55 °C @ 50 °C

** Clamping pressure must be set to the recommended level to avoid leaks.

3.3 Hold-up Volume and Minimum Working Volume

It is imperative to determine the hold-up volume and minimum working volume for your system

following installation of cassettes and prior to flushing out the system.

Feed/Retentate Hold-up Volume is the total volume, most of which is recoverable, contained

within the feed/retentate flow path.

Minimum Working Volume is the hold-up volume plus a minimum volume of liquid that must

remain in the bottom of the feed tank at the operating flow rate to prevent air from being drawn

into the cassette system.

The minimum working volume limits the maximum concentration factor achievable. It is affected

by the cross flow rate. At a higher cross flow rate, a greater liquid volume in the bottom of the

feed tank is required to prevent air from getting drawn into the pump. Tank design significantly

affects the minimum volume required to prevent air from getting into the system.

Permeate Hold-up Volume is the total volume contained within the permeate flow path.

Non-Recoverable Volume is the volume remaining in the Feed/Retentate flow path after the flow

channel has been pumped out and drained. Optimization of the product recovery step will

ensure high product recovery.

3.3.1 Determining Feed/Retentate Hold-up Volume

This procedure assumes the system is dry and cassettes have just been installed,

and that the retentate line is flexible and can be directed either to the feed tank

or the drain.

1. Add a measured volume of water into the feed tank that will be at least three times

the expected hold-up volume for the system. Record the volume. (If insufficient

volume was used, more can be added later.) Use the following table as a guide.

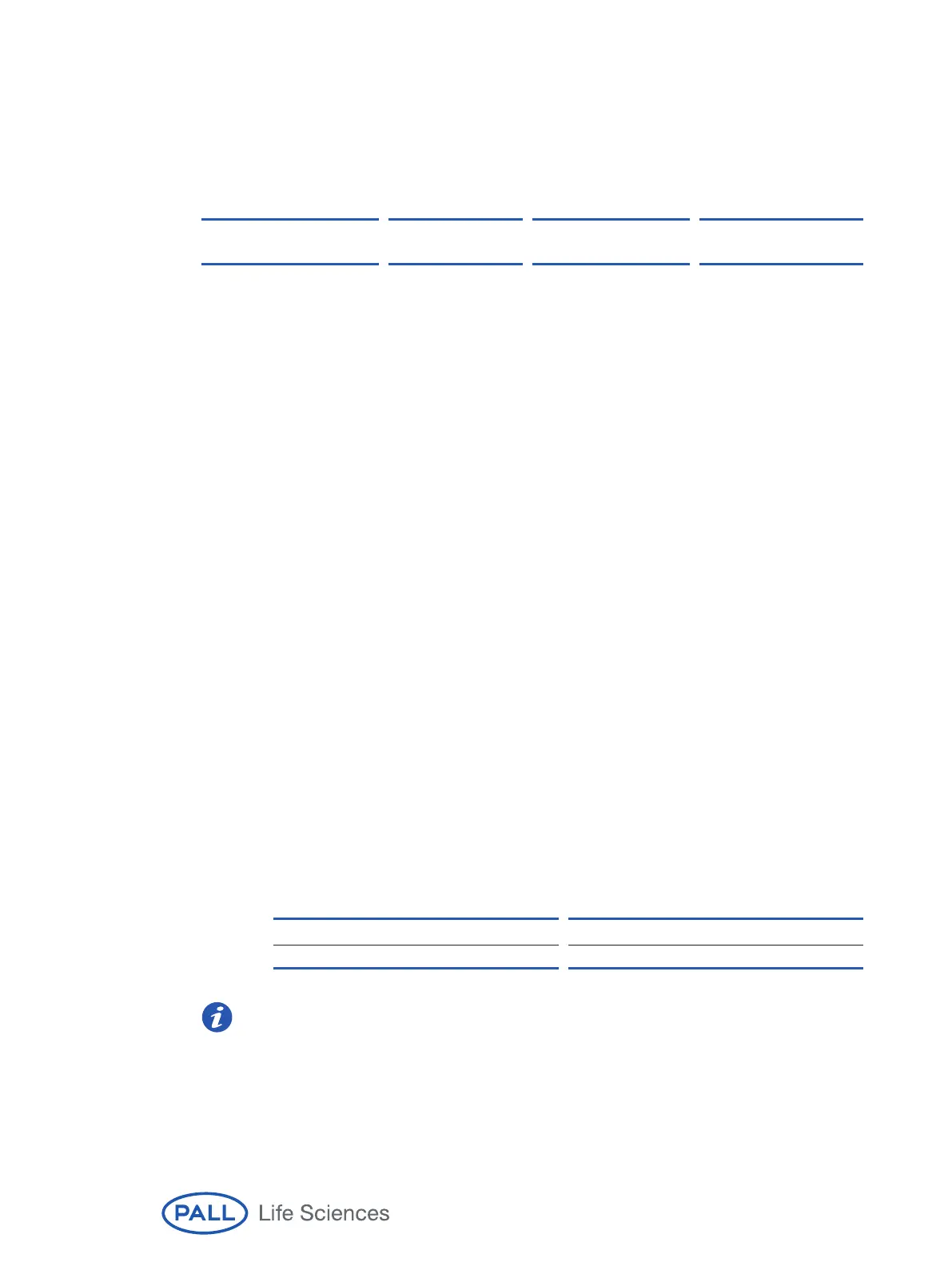

Table 5

Required Volumes for Determining Feed/Retentate Hold-up Volume

System Approximate Volume to Add

1

Centramate 300 – 500 mL

Centrasette 1 – 3 L

1

Actual volume will depend on tubing / piping diameter and lengths, as well as amount of membrane area

installed.

Note: For bench-top systems with flexible hoses on the feed and retentate lines, add

a measured volume of water to a graduated cylinder and place the ends of the feed

and retentate tubing into the cylinder.

2. Close the permeate valve.

3. Open the retentate valve completely.

Loading...

Loading...