7www.pall.com/biopharm

include protocols for Pall T-Series screen channel cassettes with Omega membrane.

Some processes may require adaptations to suit the specific requirements of a given system

configuration or application, but essential protocols should not be omitted.

To perform these procedures, it is recommended that the TFF assembly include 3 pressure

gauges/transducers and 2 valves for proper execution of the protocols presented,

see Figure 2. To include integrity testing capability (highly recommended), additional valves may

be required (Figure 22).

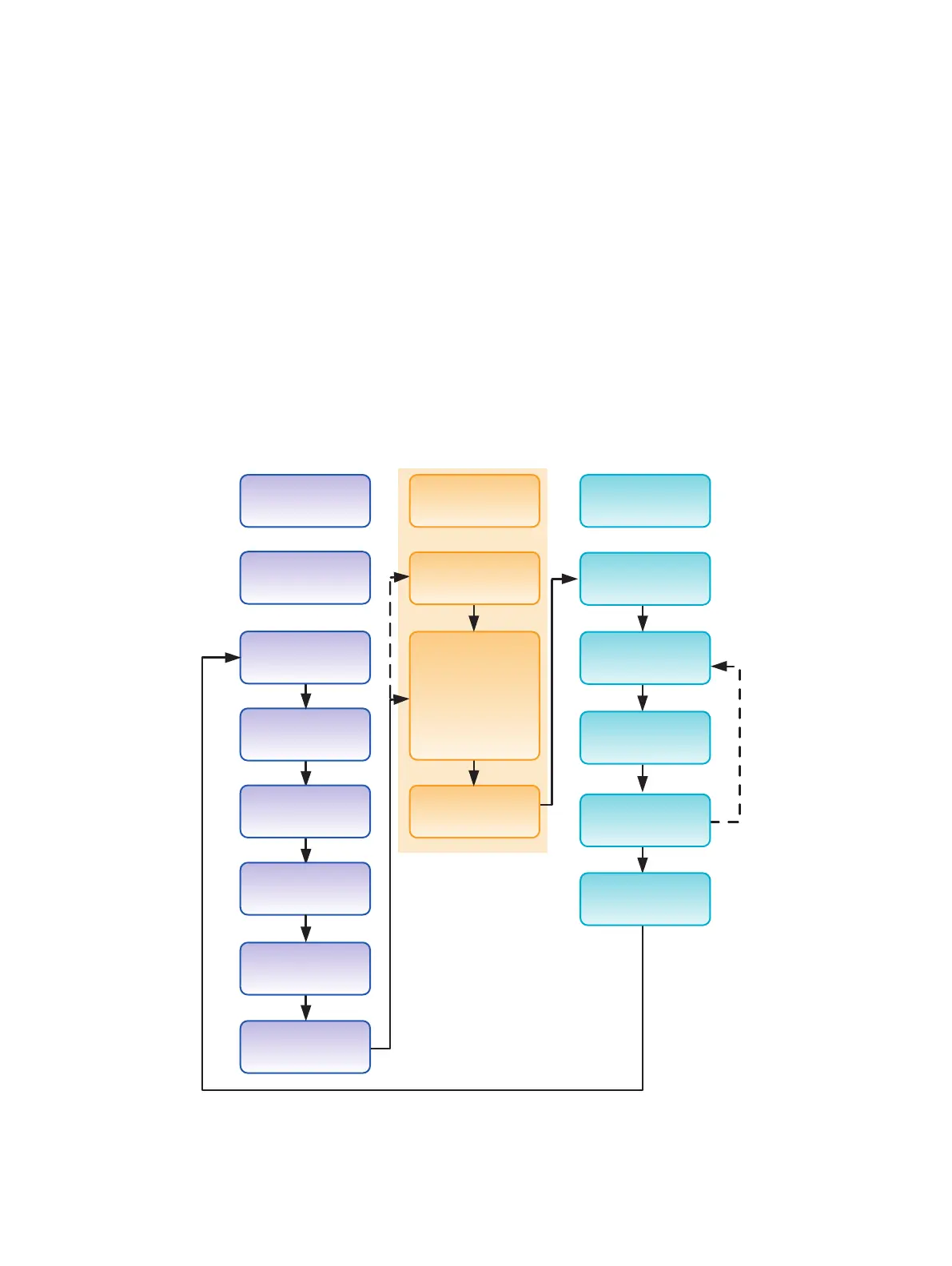

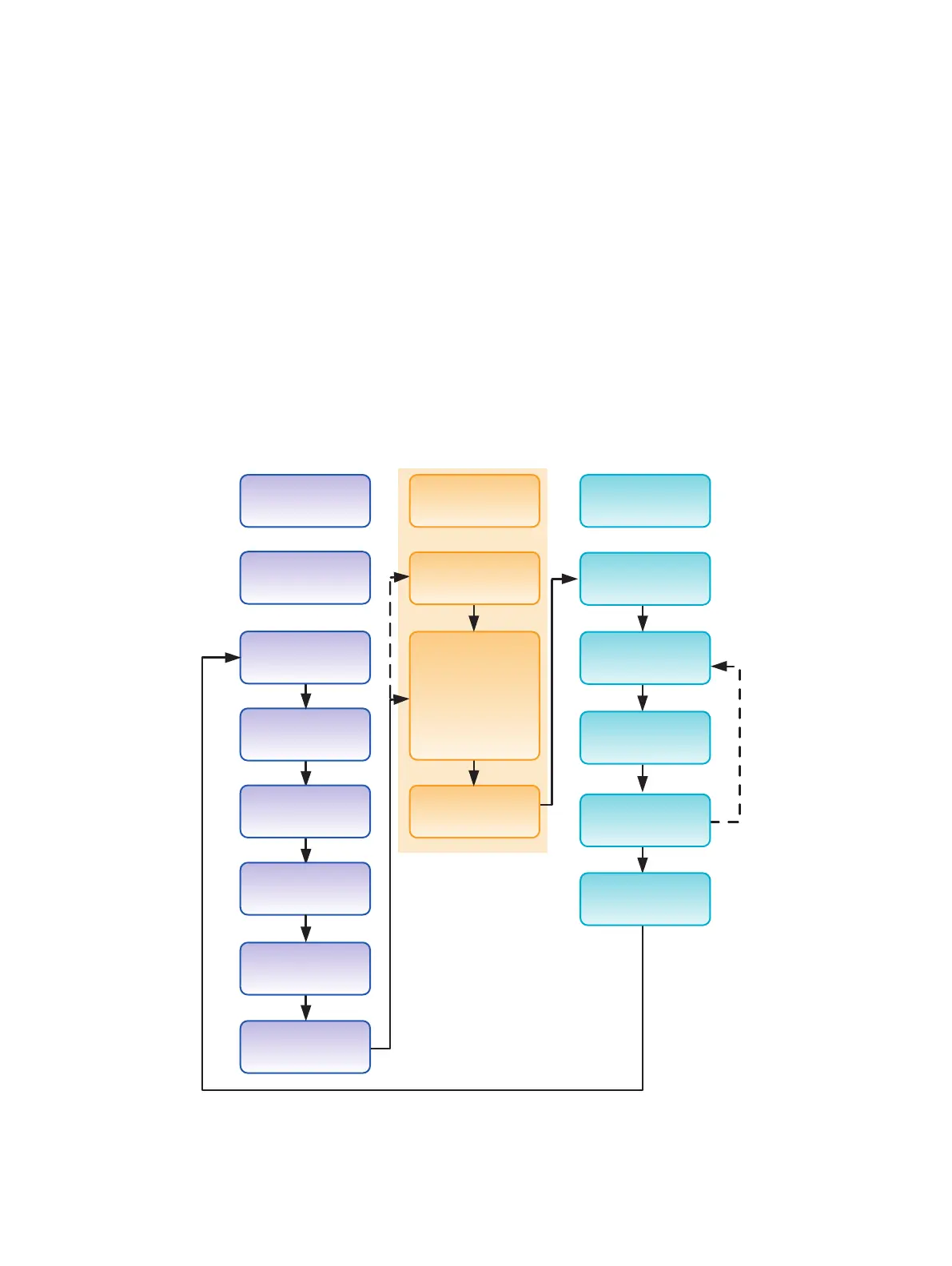

1.3 The TFF Process

The steps required in a Tangential Flow Filtration process are displayed in Figure 1.

Preconditioning and post-use conditioning are covered in Sections 4 and 5 of this manual.

Information on product process optimization and processing can be found in other supporting

literature, at www.pall.com or through Pall Life Sciences Technical Support:

• PN33289 Diafiltration: A Fast Efficient Method for Desalting or Buffer Exchange of Biological

Samples

• PN33213 Introduction to TFF for Laboratory and Process Development Applications

Figure 1

The TFF Process

Pre-use

Conditioning

Processing

Post-use

Conditioning

1. Installation

2. Flushing

3. Sanitization

2. Flushing

4. Normalized Water

Permeability (NWP)

5. Integrity Test

6. Buffer

Conditioning

8 and 9.

Concentration

and/or

Diafiltration

10. Product

Recovery

11. Buffer Flush

12. Clean In

Place (CIP)

2. Flushing

4. Normalized

Water Permeability

13. Storage

7. Optimization

(Once only)

Loading...

Loading...