40

5.3.1 Flush the Retentate Line to Waste

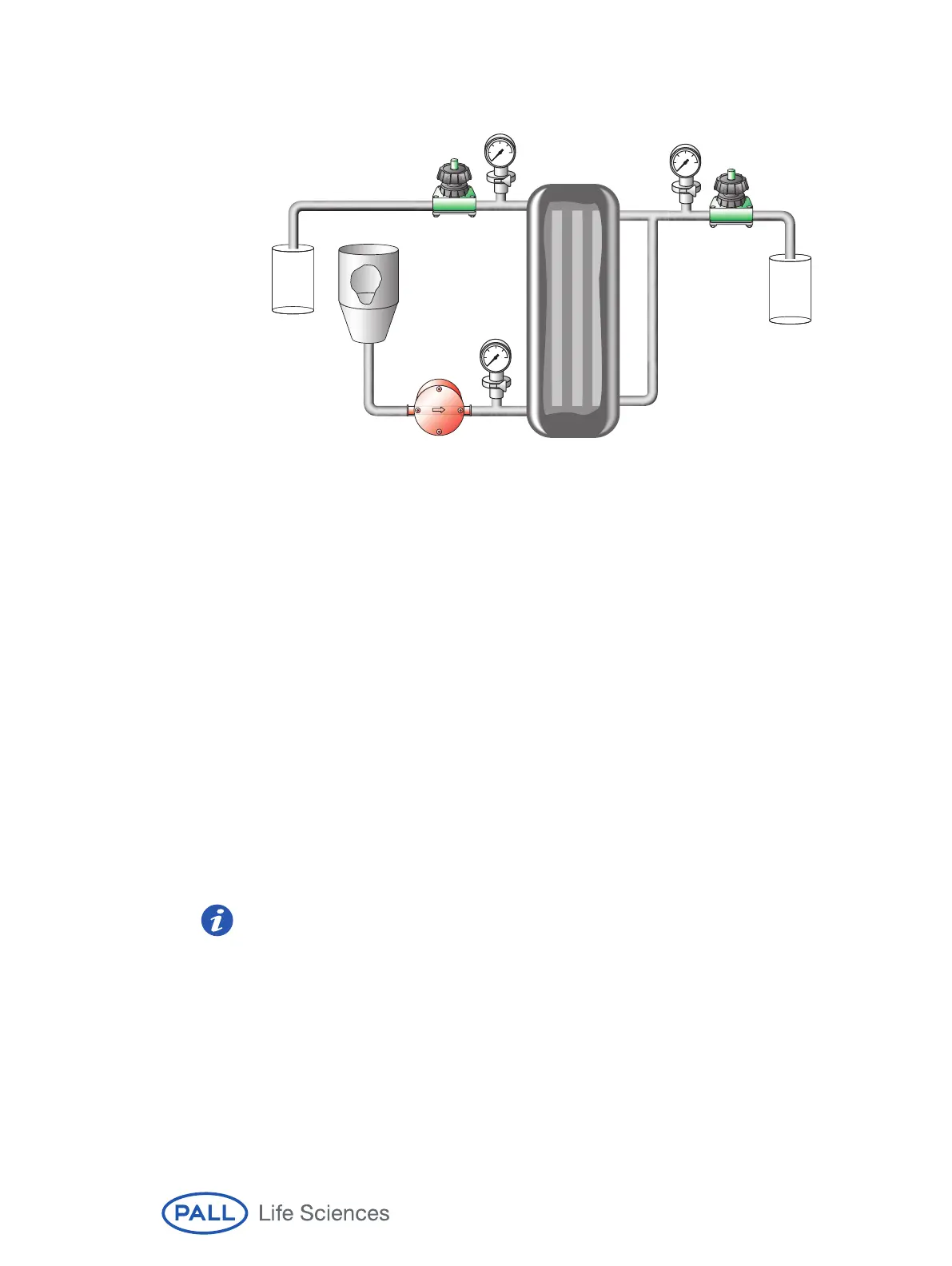

Figure 29

System Setup for Flushing Cleaning Solution to Waste

1. Drain, wash, and refill the feed tank with water (or attach the feed line to the water

supply).

2. Open the retentate and permeate valve.

3. Adjust the pump to deliver a flow rate of 5 to 10 L/min/m

2

(0.5 to 1 L/min/ft

2

).

Do not exceed a feed pressure of 2 barg (30 psig). If necessary, restrict the

permeate valve so at least 50% of flow is from the retentate line.

4. Pass 10 to 20 L/m

2

(1 to 2 L/ft

2

) through the retentate to waste.

5. Stop the pump.

5.3.2 Flush the Permeate Line to Waste

1. Close the retentate valve.

2. Open the permeate valve

3. Adjust the pump to deliver a flow rate of 5 L/min/m

2

(0.5 L/min/ft

2

) or until the feed

pressure equals 2 barg (30 psig).

4. Open the retentate valve until the retentate flow rate is 5 to 10% of the permeate

flow rate.

5. Run until a minimum of 20 L/m

2

(2 L/ft

2

) is flushed through the permeate, or until

the pH and/or TOC has reached an acceptable value — normally close or equal to

the pH/TOC of the incoming water.

The addition of one or more recirculation steps through both retentate and permeate

can be used to reduce the total volume of water needed to achieve the required pH,

TOC, or extractable levels. See Section 5.3.3.

5.3.3 Recirculation Procedure to Reduce pH, TOC, and Extractables (optional)

Volume Required:

8 L/m

2

(0.8 L/ft

2

) per cycle

Temperature Range: 25 to 45 °C

Retentate

Permeate

Feed

Tank

Waste

Waste

Feed

Pump

Pp

Rp

Fp

Loading...

Loading...