47

12.1.6.1 Wire Stripping and Connecting Requirement

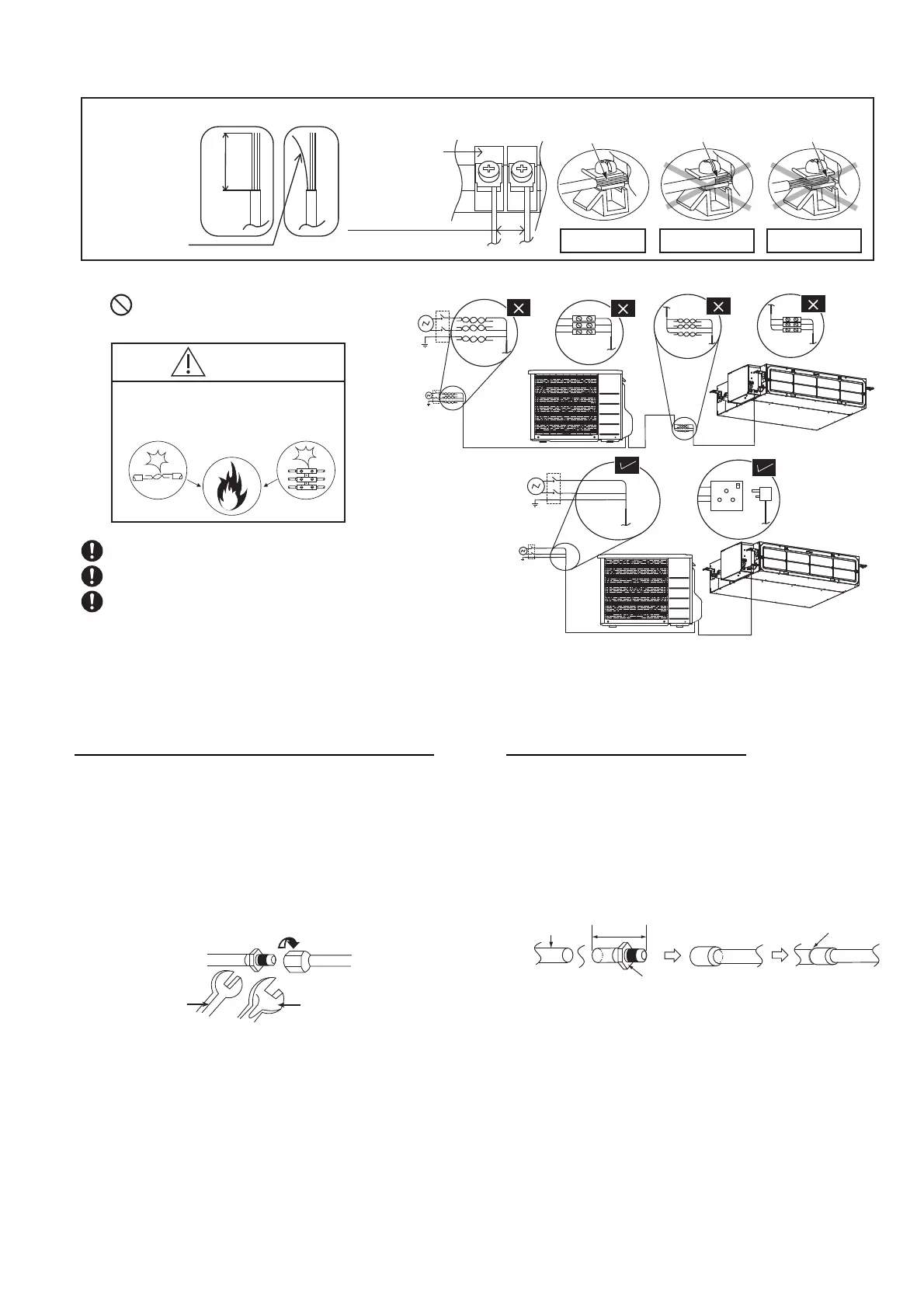

WARNING

RISK OF FIRE

JOINING OF WIRES MAY CAUSE

OVERHEATING AND FIRE.

Do not joint wires

OR

OR

OR

Use complete wire without joining.

Use approved socket and plug with earth pin.

Wire connection in this area must follow to national

wiring rules.

Conductor

over inserted

Conductor

fully inserted

Conductor not

fully inserted

5 mm

or more

Indoor/outdoor

connection

terminal board

(gap between wires)

ACCEPT PROHIBITED PROHIBITED

Wire stripping

No loose strand

when inserted

10 ± 1 mm

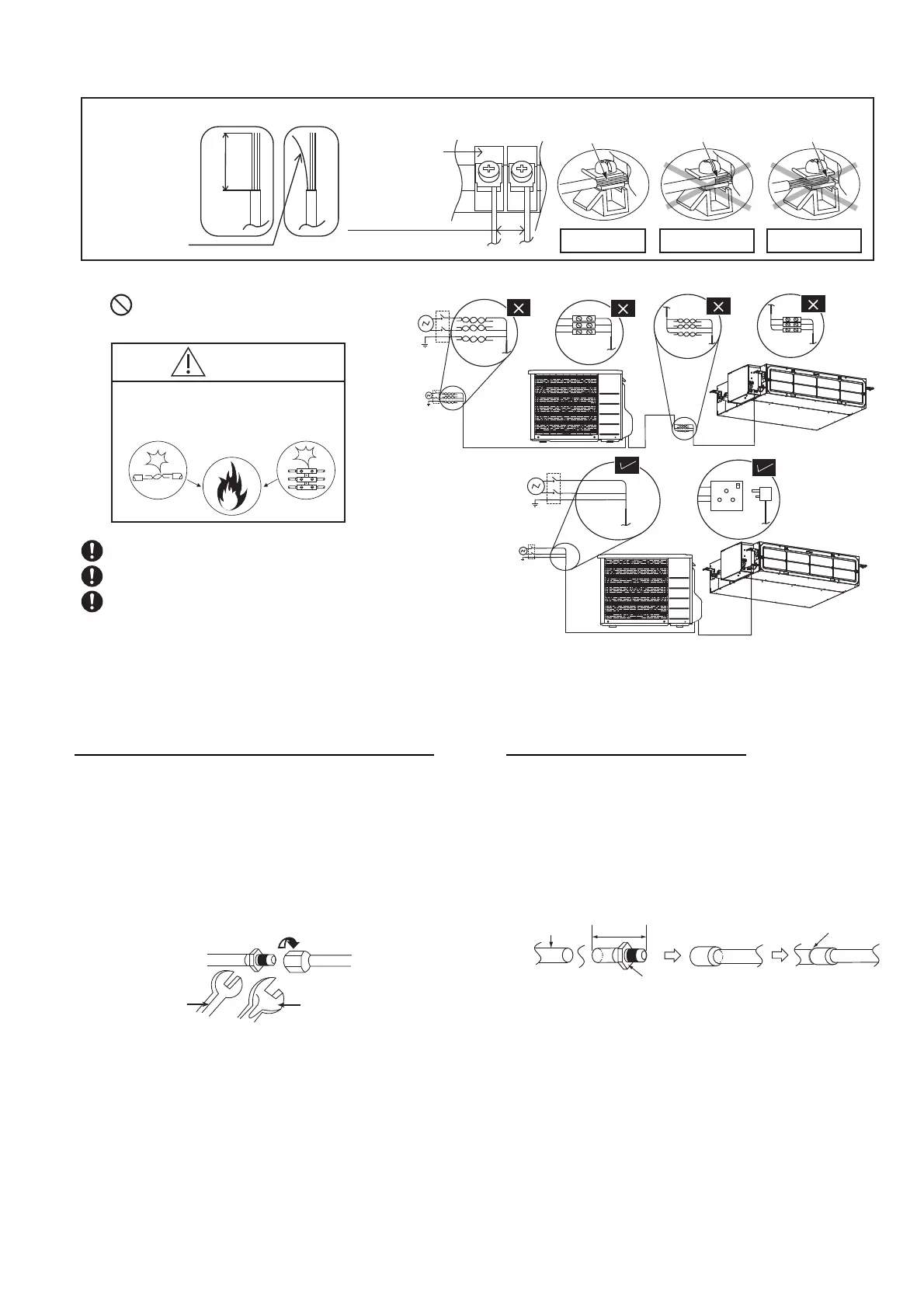

12.1.7 Connect the Piping

12.1.7.1 Connecting the Piping to Indoor

For connection joint of all model (except R32 model)

Please make flare after inserting flare nut (locate at

joint portion of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

Align the center of piping and sufficiently tighten

the flare nut with fingers.

Further tighten the flare nut with torque wrench in

specified torque as stated in the table.

Torque wrench

Spanner or

Wrench

For connection joint of R32 models

Decide the length.

Cut and remove the tube connectors at indoor

copper pipings (both gas and liquid piping) by

using pipe cutter. Remove burrs from cut edge.

Use pipe expander to expand the end of long

piping.

Align the center of piping and braze the piping

joints.

Indoor copper pipe

Tube connector

(40~50mm)

Brazing point

1. Cut and Remove 2. Expand long pipe 3. Braze both pipe

Braze the piping joints carefully so that the indoor

unit is not damaged by brazing flame.

If necessary, cover with wet clothes to prevent

parts unintentionally overburnt.

Loading...

Loading...