24

Lo Hi

R410A

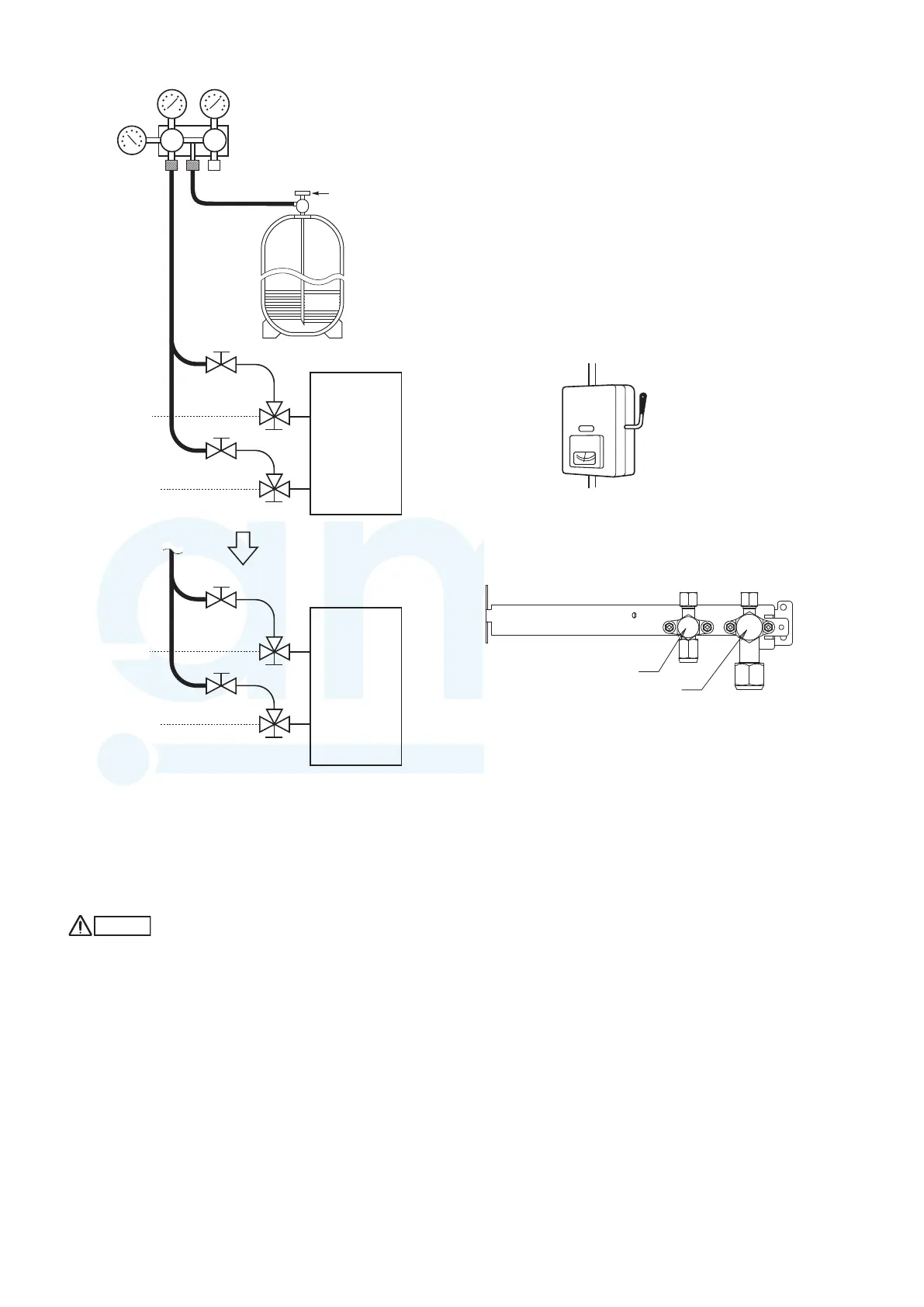

Fig. 6-5

Fig. 6-6

Finishing the job

(1) With a hex wrench, turn the liquid tube service valve stem

counterclockwise to fully open the valve.

(2) Turn the gas tube service valve stem counterclockwise to

fully open the valve.

CAUTION

To avoid gas from leaking when removing the charge hose,

make sure the stem of the gas tube is turned all the way

out.

(3) Loosen the charge hose connected to the gas tube service

port (for ø 7.94 mm tube) slightly to release the pressure,

then remove the hose.

(4) Replace the service port cap on the gas tube service port

and fasten the cap securely with an adjustable wrench or

box wrench. This process is very important to prevent gas

from leaking from the system.

(5) Replace the valve caps at both gas tube and liquid tube

service valves and fasten them securely.

This completes air purging with a vacuum pump. The air

conditioner is now ready for a test run. Refer to Section

“7. TEST RUN”.

Manifold valve

Pressure

gauge

Gas tube

Liquid tube

Open

Close

Close

Close

Outdoor unit

Valve

Liquid

Gas tube

Liquid tube

Close

Open

Open

Open

Outdoor unit

7. TEST RUN

7-1. Preparing for Test Run

● Before attempting to start the air conditioner, check the

following points.

(1) All loose matter is removed from the cabinet especially

steel filings, bits of wire, and clips.

(2) The control wiring is correctly connected and all electrical

connections are tight.

(3) The transportation pads for the indoor fan have been

removed. If not, remove them now.

(4) The power has been supplied to the unit for at least 5

hours before starting the compressor. The bottom of

the compressor should be warm to the touch and the

crankcase heater around the feet of the compressor should

be hot to the touch. (Fig. 7-1)

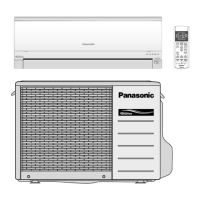

Fig. 7-1

(5) Both the gas and liquid tube service valves are open.

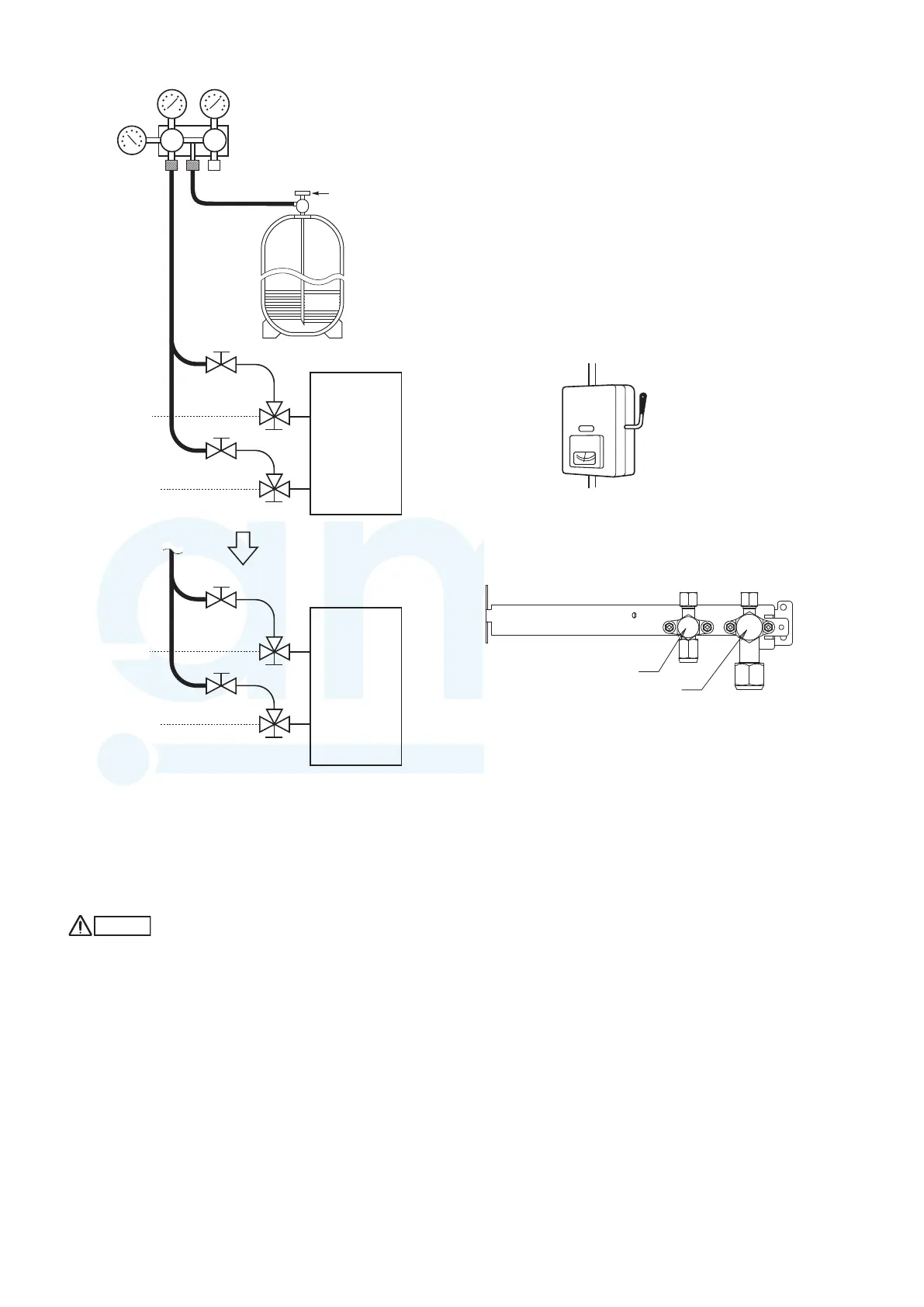

If not, open them now. (Fig. 7-2)

Fig. 7-2

(6) Request that the customer be present for the test run.

Explain the contents of the instruction manual, and then

have the customer actually operate the system.

(7) Be sure to give the instruction manual and warranty

certificate to the customer.

(8) When replacing the control PCB, be sure to make all the

same settings on the new PCB as were in use before

replacement.

The existing EEPROM is not changed, and is connected to

the new control PCB.

ON

(Power must be turned ON at least

5 hours before attempting test run)

Power mains switch

Liquid tube service cap

Gas tube service cap

MiniVRFeng.indd24MiniVRFeng.indd24 2011/08/2613:45:222011/08/2613:45:22

www.ampair.co.uk | sales@ampair.co.uk

Loading...

Loading...