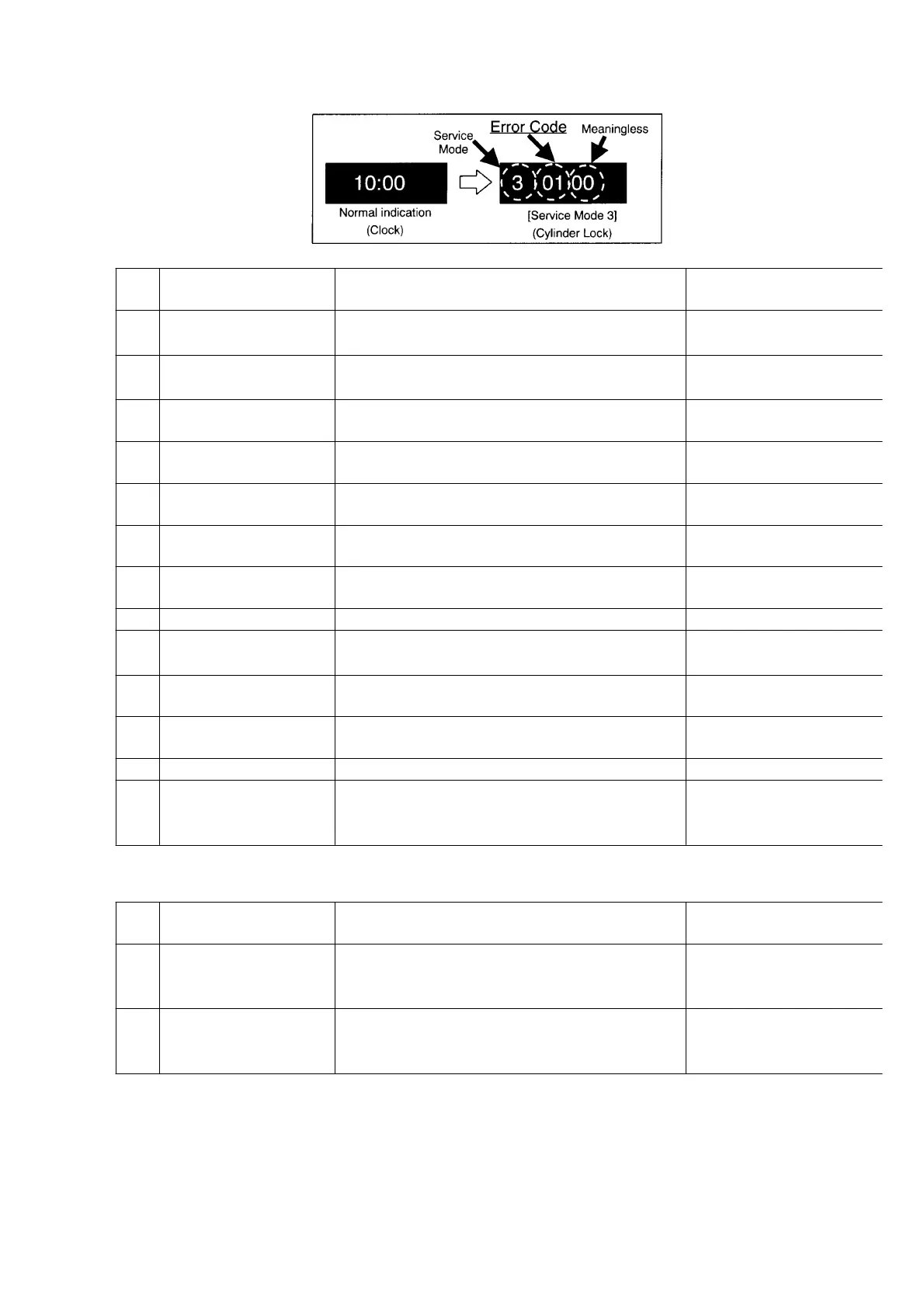

Error

Code

Condition Description Remedy/Check

01 Cylinder Lock The cylinder does not rotate or Cylinder lock has

been detected during normal rotation.

Check the Cylinder

Cylinder Drive IC

02 Capstan Lock FG signal does not existed in the Cassette down

position (Eject-Rev.).

Check the Capstan

Capstan Drive IC

03 Loading Lock Mechanism Lock has been detected during

loading operation.

Loading Post

04 Unloading Lock Mechanism Lock has been detected during

unloading operation.

Loading Post

05 Reel FG NG Abnormal Reel FG has been detected during

loading/unloading operation.

Reel FG line

07 Slot Motor Lock Slot motor lock has been detected during slot

in/out operation.

Slot Motor

09 Communication Error

(Sys-Timer)

"SYSCON-TIMER" Communication error has

been detected.

Communication-line

11 Head Clogging Head clogging has been detected. Head cleaning

14 Mode error Cassette down position has been detected during

unloading operation.

Loading Motor Drive

Mode Switch

17 S-Reel Lock S-Reel Lock has been detected during normal

rotation.

S-Reel

18 T-Reel Lock T-Reel Lock has been detected during normal

rotation.

T-Reel

19 Fan Motor Lock Fan motor does not rotate after turning power ON. Fan motor

51 S-Photo Tr Adj. Error

Adjustment Error.

(Adjustment error of S-Photo Transistor sensitivity

Adjustment.)

Re-adjustment is required.

(Tape End Sensor

Adjustment.)

(To be continued.)

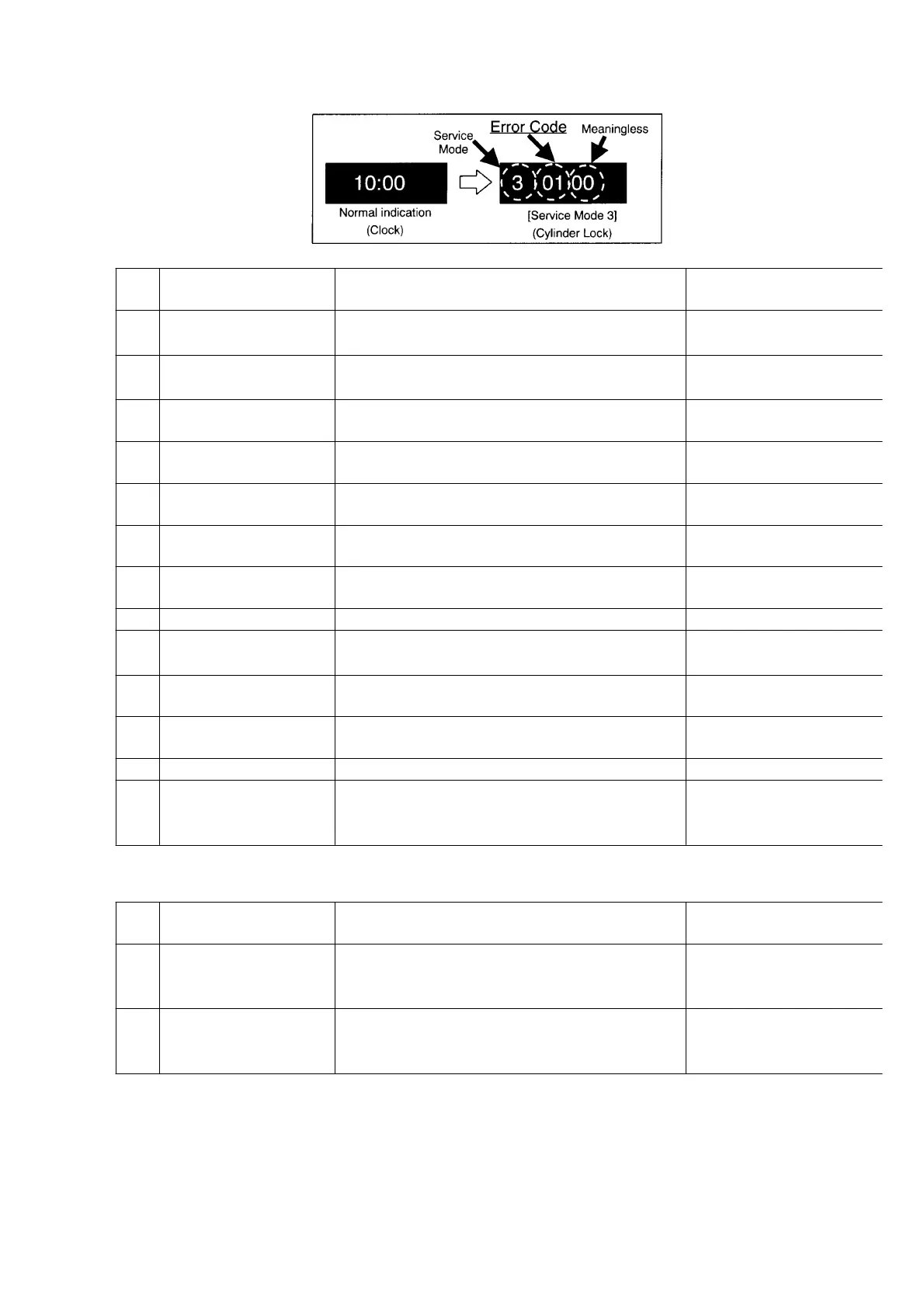

Error

Code

Condition Description Remedy/Check

52 T-Photo Tr Adj. Error

Adjustment Error.

(Adjustment error of T-Photo Transistor sensitivity

Adjustment.)

Re-adjustment is required.

(Tape Beg. Sensor

Adjustment.)

53 S/T-Photo Tr Adj. Error

Adjustment Error.

(Adjustment error of S/T-Photo Transistor

sensitivity Adjustment.)

Re-adjustment is required.

(Tape End/Beg. Sensor

Adjustment.)

Fig. 2-8 Error Code (Displayed in Service Mode 3, 4 and 5)

2.2.4. Emergency Tape Ejection

If the electric circuit defects and no Tape ejection can be made in regular way, try following methods.There are

two methods to achieve the emergency tape ejection.

Loading...

Loading...