24

Pilot Operated Prop. DC Valve with VCD

®

Series D*1FP/FE Explosion Proof

Operation Manual

Parker Hannifin Corporation

MSG11-5715-718 D_1FP IECEX UK.indd 19.12.19

Regular maintenance is essential in prolonging

the service life of the systems, and safeguards

plant safety and operational availability. The fol-

lowing items must be checked at regular and

short intervals:

• Oil level in tank

• Max. medium temperature

• Max. surface temperature

• Condition of the pressure uid (sight check,

colour and smell of hydraulic uid)

• Operating pressures

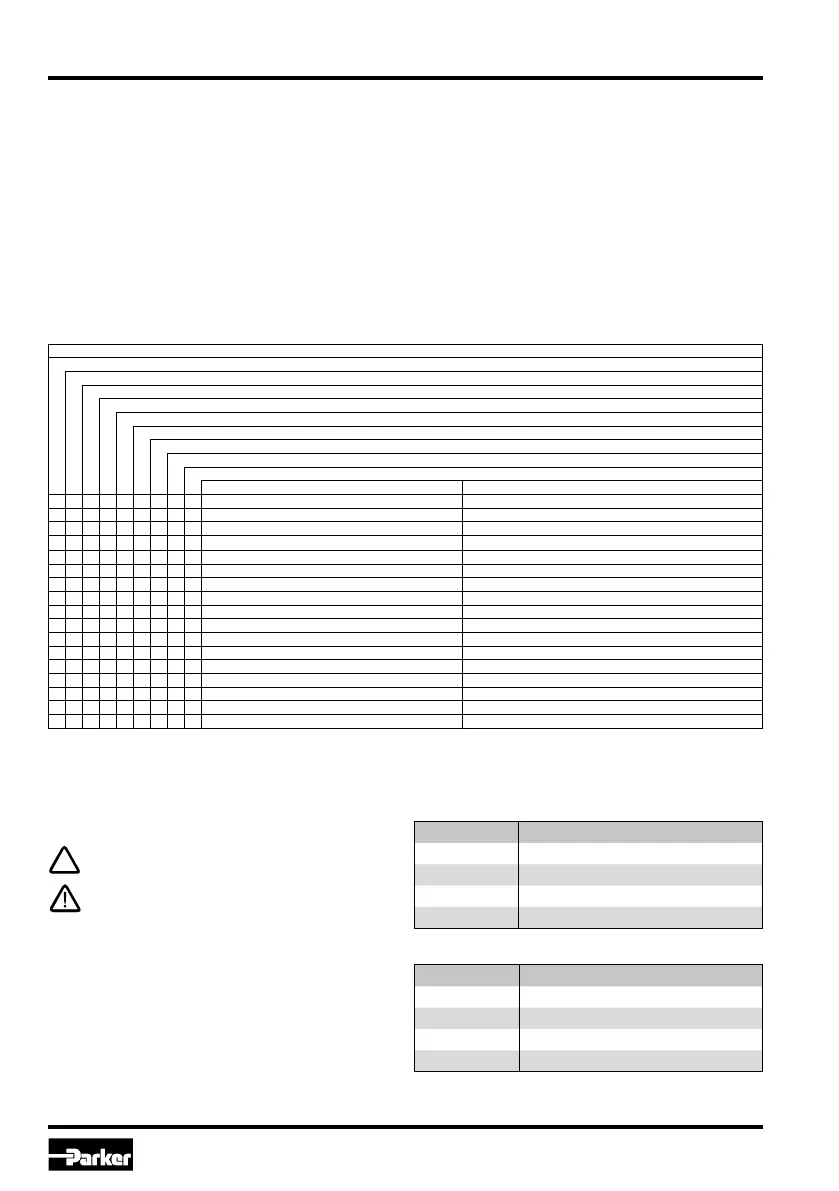

malfunction at hydraulic load runtime

- generally no function

- high frequent oscillation

- low frequent oscillation

- one way operation only

- speed variations at unchanging command

- different speeds depending on travel direction

- speed too low

- drifting without command

- poor dynamic

possible reasons for malfunction corrective actions

X hydraulic pump resp. motor defective replace hydraulic pump resp. motor

X X X X X X X drive overloaded reduce pressure resp. speed, increase valve size

X X X X X X X X valve contaminated clean pressure uid, lter / ush valve

X X X hydraulic uid too viscous / too cold change uid grade, provide operational temperature

X X X too low oil level within tank rell pressure uid

X X X lter contaminated replace lter

X X X X supply voltage too low keep supply voltage range

X supply voltage carries too much ripple reduce ripple

X X X command signal too low increase command signal

X command signal carries too much ripple reduce ripple

X X X X X contacts of central connector contaminated clean contacts / replace plug

X feed cable interrupted x feed cable

X X X X X X X wiring sequence incorrect correct wiring sequence

X X feed cable without shielding change cable grade

X pilot pressure too low or failed increase pilot pressure to min. 20 bar

X X X pilot pressure too low increase pilot pressure to min. 20 bar

X pilot pressure too low increase pilot pressure to min. 50 bar

• Preload pressure of pressure vessel (if present)

• No leaks at any system components

• Condition of the lter elements

• Condition of the hose lines

• Cleanliness of components

After a certain period of service, the hydraulic uid

must be replaced. The frequency of the change

depends on the following circumstances:

• Type and grade of pressure uid (ageing)

• Filtration

• Operating temperature and ambient condi-

tions

8. Trouble Shooting

Basis of troubleshooting is always a systematic

approach.

For suspect of a sluggish spool the valve

may be ushed with clean pressure uid.

Troubleshooting in a hydraulic system re-

quires detailed knowledge about function

and construction of the system. Therefore

the work may exclusively be performed by

qualied personnel.

9. Accessories / Spare Parts

Accessories

The following accessories are available for the

valve series D*1FP and D*1FE:

Mounting bolts see table on page 12.

Spare Parts

The following accessories are available:

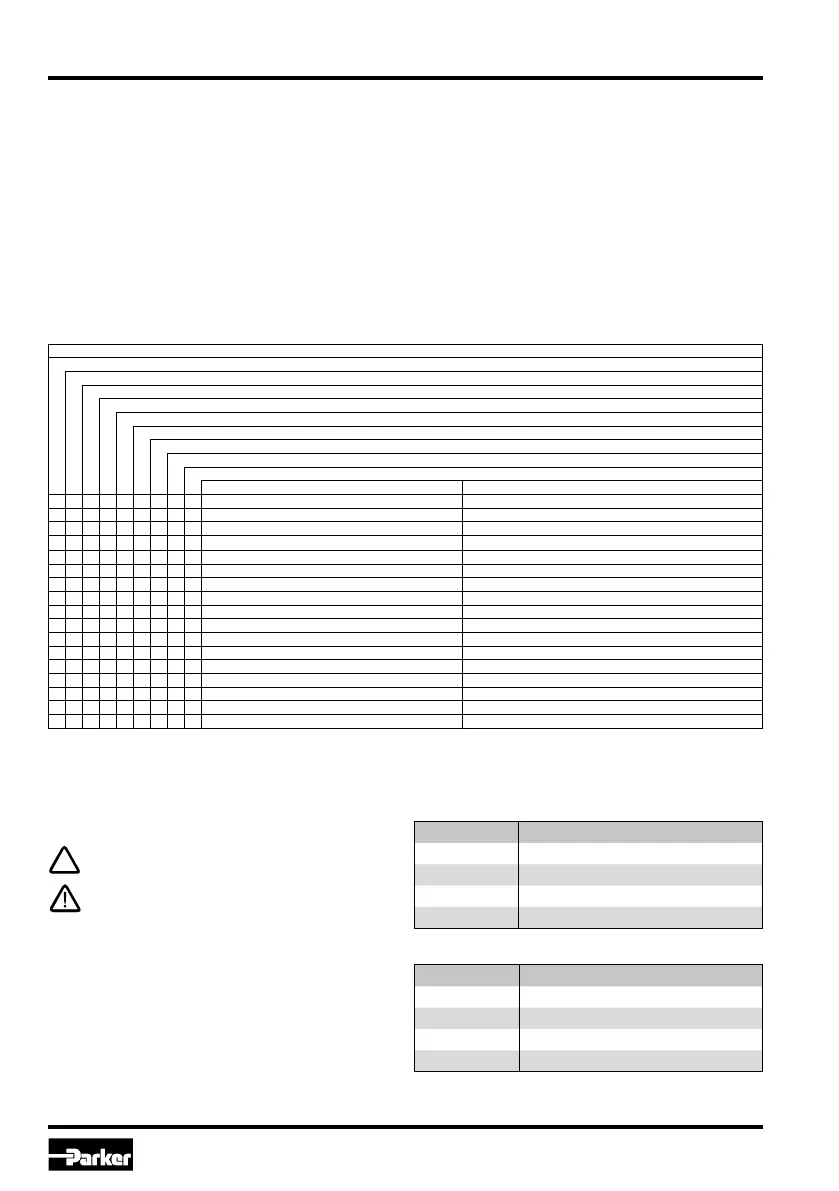

Valve type NBR

D41FP SK-D41FP

D81FP SK-D81FP

D91FP SK-D91FP

D111FP SK-D111FP

Valve type NBR

D41FE SK-D41FE

D81FE SK-D81FE

D91FE SK-D91FE

D111FE SK-D111FE

Loading...

Loading...