Pilot Operated Prop. DC Valve with VCD

®

Series D*1FP/FE Explosion Proof

Operation Manual

23

Parker Hannifin Corporation

MSG11-5715-718 D_1FP IECEX UK.indd 19.12.19

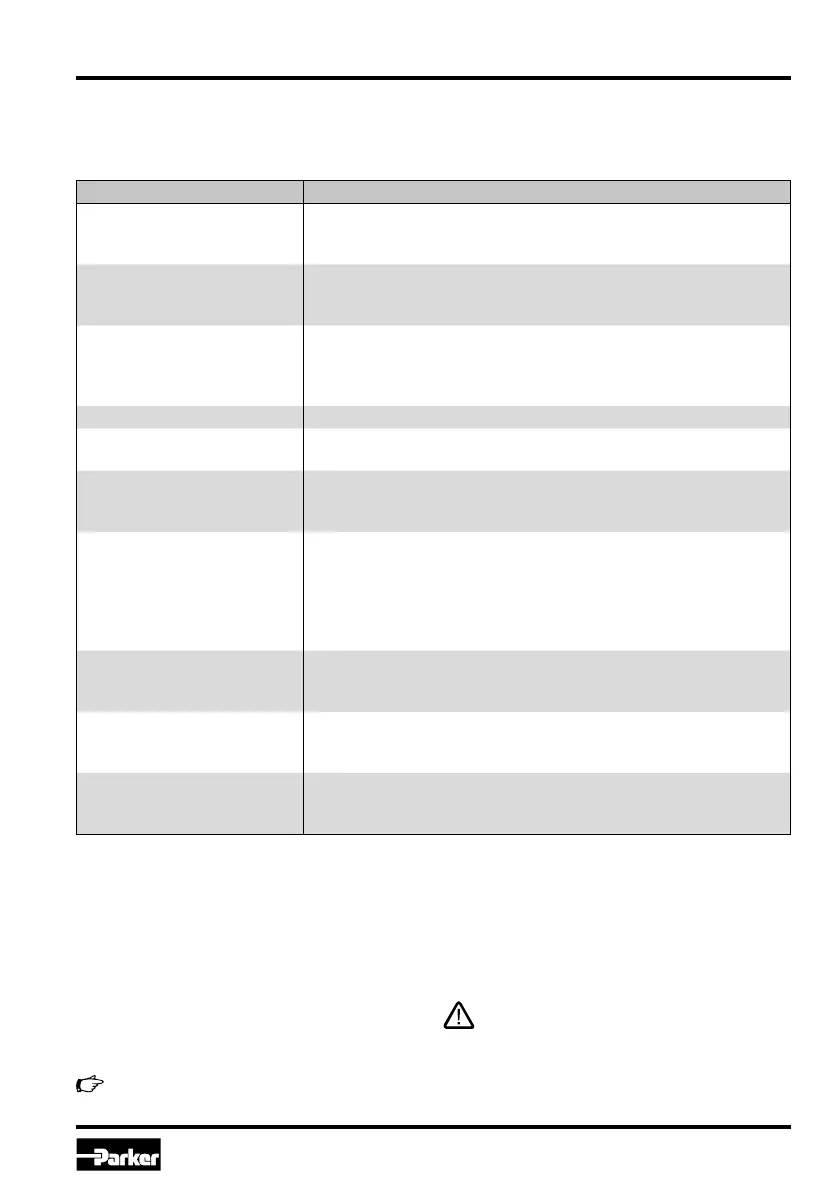

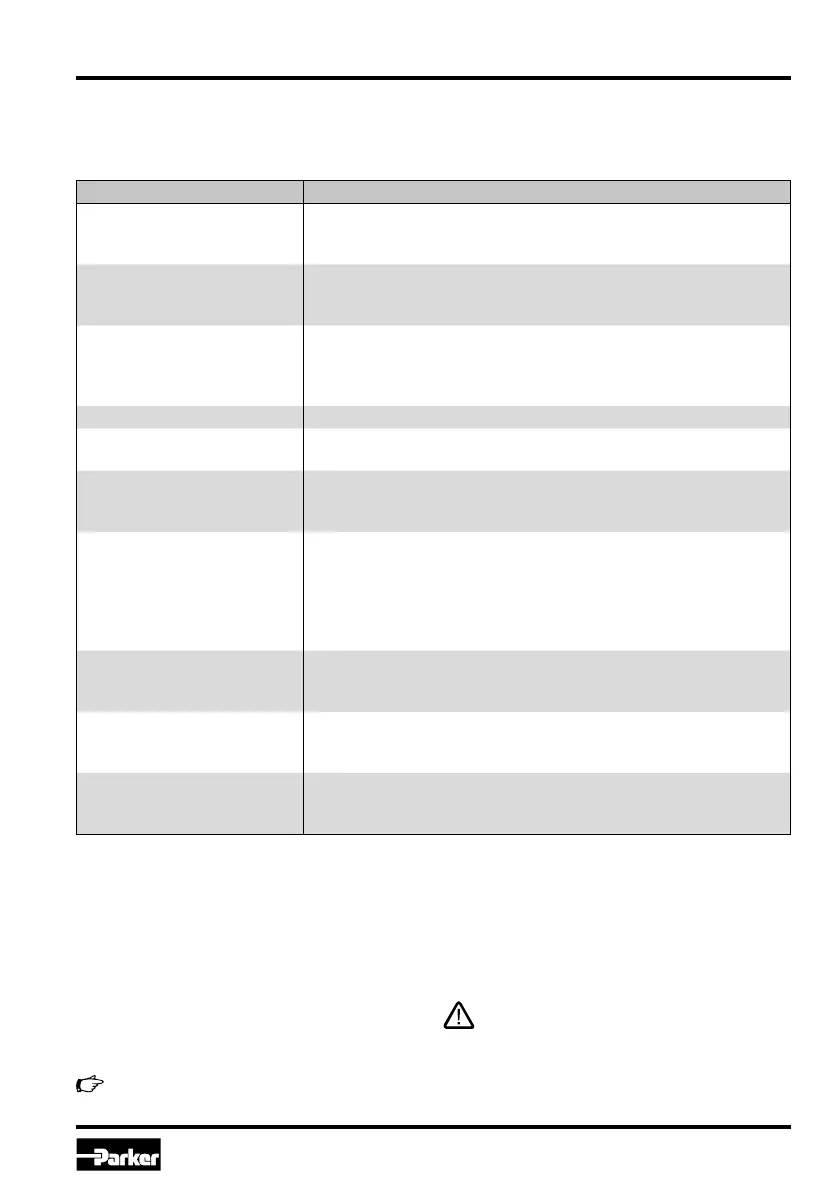

Failure message Description/corrective action

The Com Port is not available! Terminate the other program, or quit the message and select

another RS232C port via the menu “Options > Port”. Afterwards

reconnect the parametrizing cable.

Unable to open COM port Com port is not available. Quit the message and select another

RS232C port via the menu “Options > Port”. Afterwards reconnect

the parametrizing cable.

There is no module/valve

connected or the communi-

cation is disturbed! Please

check also the interface!

No data exchange possible. Either the electronic has been re-

moved, the port is mismatched, or the connection will be dis-

turbed by strong electrical elds. Check if the Com port is set for

“9600, 8, 1. none, none” via the menu “Options > Port”.

Wrong password Retype the password, notice the exact spelling (case sensitivity).

Wrong input An unvalid character or a value outside the permitted range has

been used at parameter entry.

Keep the entered param-

eters?

During parameter loading from the electronics memory the preset

parameters from the left hand screen display may be rejected or

maintained.

The chosen module/valve

isn´t the same as the con-

nected hardware. Attention!

Unsaved parameters will be

lost.

In principle, parameters dedicated to a type which deviates from

the connected valve may be edited. However, for data transmit-

ting the correct valve has to be connected. If parameters will be

loaded from a valve which deviates from the selected one, the

parameters from the left hand side screen display of the program

will be overwritten.

The chosen hardware isn´t the

same as the connected mod-

ule/valve.

The wrong valve type has been selected from the database, after-

wards the function “send all” has been executed.

Attention! Factory settings

will be changed! Transmit

anyhow?

Default parameters has been read out from the database instead

from the valve via the function “receive all”.

le name.pxd already exists.

Do you want to replace the

le?

The le name already exists within the indicated directory. Select

another name, another directory or overwrite the existing le with

“OK”.

Error messages

Malfunctions when using the ProPxD software program will be indicated via appropriate failure messages.

Failure messages and corrective actions:

Air bleeding of hydraulic system

During initial startup, after an oil change as well as

after the opening of lines or valves the hydraulic

system must be air bleeded.

Filter

The function and lifetime of the valve are strongly

affected by the cleanliness of the uid.

Purity level class of 18/16/13 acc. ISO4406 is

required.

Pay attention to maintenance details!

Flushing

It is recommended to ush the pipelines by short

circuiting the pressure and return lines. This pre-

vents the installation dirt from entering the valve.

7. Maintenance

Maintenance procedures may only be car-

ried out by specialist personnel. A detailed

knowledge is required of how the machine

is switched on and off and also of the ne-

cessary safety measures.

Loading...

Loading...