Pilot Operated Prop. DC Valve with VCD

®

Series D*1FP/FE Explosion Proof

Operation Manual

27

Parker Hannifin Corporation

MSG11-5715-718 D_1FP IECEX UK.indd 19.12.19

INSTALLATION INSTRUCTIONS FOR CMP CABLE GLAND T3CDS & T3CDSPB

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

www.cmp-products.com

www.cmp-products.com

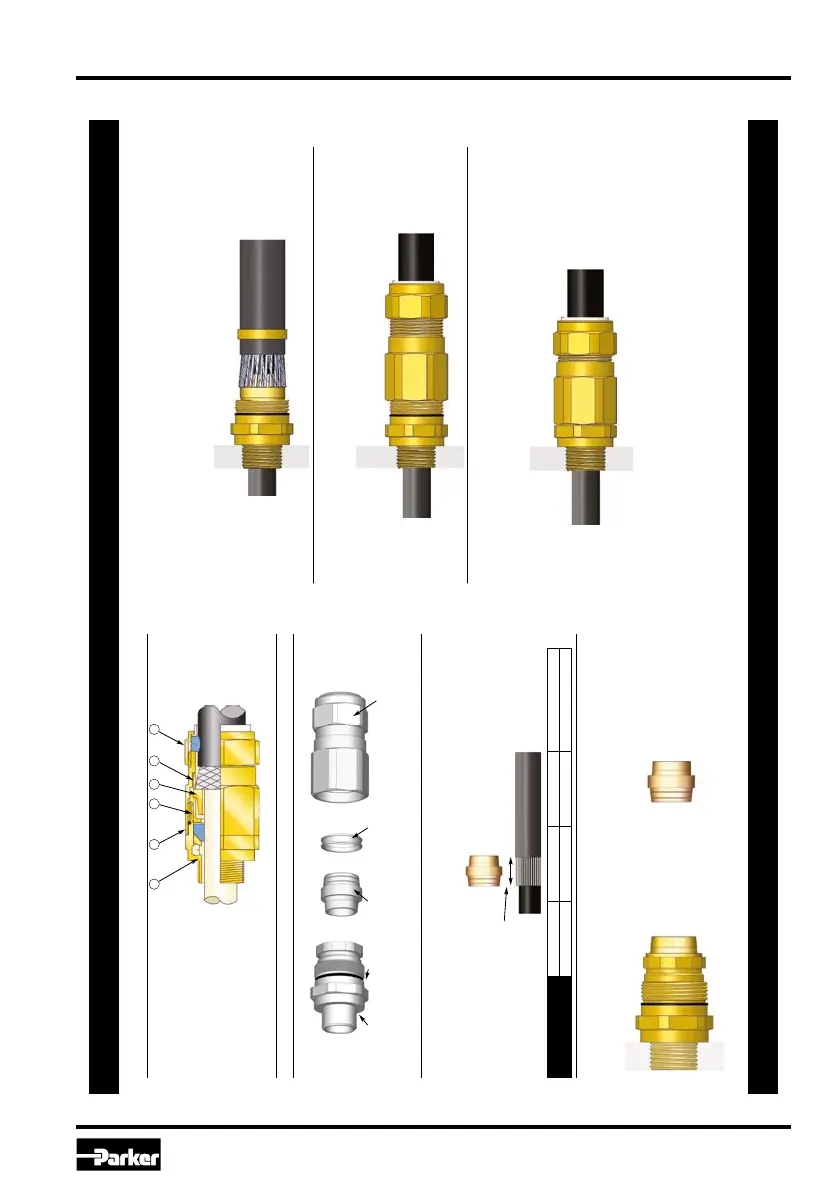

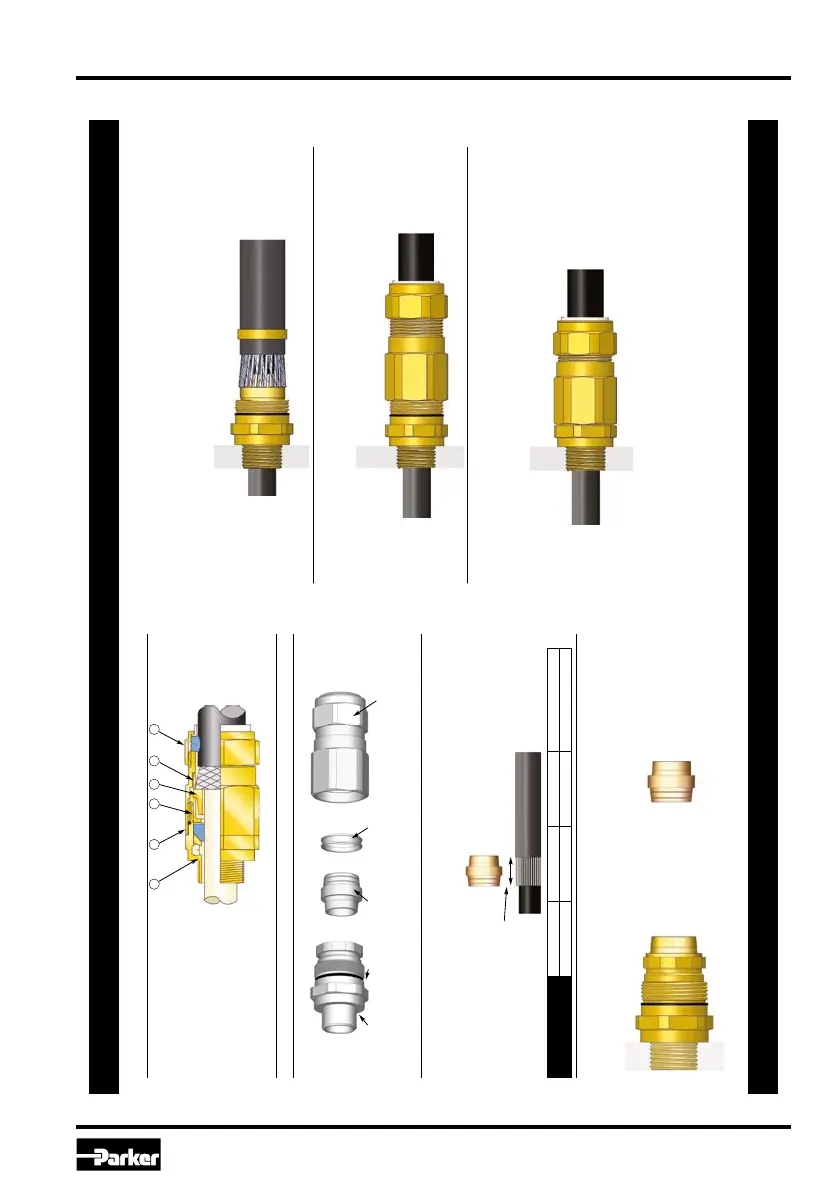

CABLE GLAND COMPONENTS

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION

1. Separate the gland into two sub-assemblies, A and B, by unscrewing the body (2) from the entry

item (1). Note that items (4) and (5) are loose items.

2. Prepare the cable by stripping back the cable outer sheath and armour to suit the equipment

geometry. Expose the armour by stripping back the outer sheath further using the table below as a

guide.

3. Secure the entry components (sub-assembly A) into the equipment. (Not for remote installation)

Pass the sub-assembly B and AnyW

ay clamping ring (5) over the cable, outer seal first.

Insert the reversible armour cone (4) in the sub-assembly B, orientated correctly:

4. Pass the cable through sub-assembly A, spacing the armour or braid evenly around the cone.

Whilst continuing to push the cable forward to keep the cable braid or armour in contact with the

cone, tighten the compensating sleeve (3) into the entry component (1) until all the threads are

used. (Note that the internal compensator will prevent the cable gland inner seal from being over-

tightened onto the cable inner sheath.)

The inner sheath of the T3CDSPB gland contains a devi

ce to automatically make an electrical

contact with the lead sheath on the cable as the cable is installed.

5. Terminate the cable by tightening the body (2) onto the entry component (1) using a spanner on

each part. Tighten the body until the body and entry components are metal to metal and cannot

be tightened further.

6. Tighten the outer seal nut (6) until it comes to an effective stop. This will occur when:-

A) The outer seal nut (6) has clearly engaged the cable and cannot be fur

ther tightened

without the use of excessive force by the installer.

B) The outer seal nut (6) is metal to metal with the body of the gland (2).

4321

1. Entry Item

2. Body

3. Compensating Sleeve

4. Reversible Armour Cone

5. AnyWay Clamping Ring

6. Outer Seal Nut

65

SUB-ASSEMBLY A

ITEM 4 ITEM 5 SUB-ASSEMBLY B

“CDS” INNER SEAL

HOUSING

DELUGE

SEAL

REVERSIBLE

ARMOUR CONE

ANYWAY

CLAMPING RING

BODY AND OUTER

SEAL NUT

CABLE GLAND SIZE 20S/16, 20S, 20 25S, 25, 32, 40 50S, 50, 63S, 63 75S, 75, 90, 100, 115, 130

CABLE STRIP LENGTH “L” 12mm 15mm 18mm 20mm

Cable Strip

Length “L”

Grooved side of cone

outwards - to

terminate braid, strip

armour, pliable wire

or tape armour.

Stepped side of cone

outwards - to

terminate SWA cable.

Loading...

Loading...