| User’s Manual

16

6.2 Inspections

To ensure proper operation of the system, maintenance must be

carried out on a regular basis.

6.2.1 Daily Inspection

Vacuum oil level.

6.2.2 Weekly Inspections

6.2.3 Yearly Inspections

Only qualified personnel should carry out the yearly inspection.

Items Inspection Activities

1 System operation

Check system operation - no unusual noise and

vibrations.

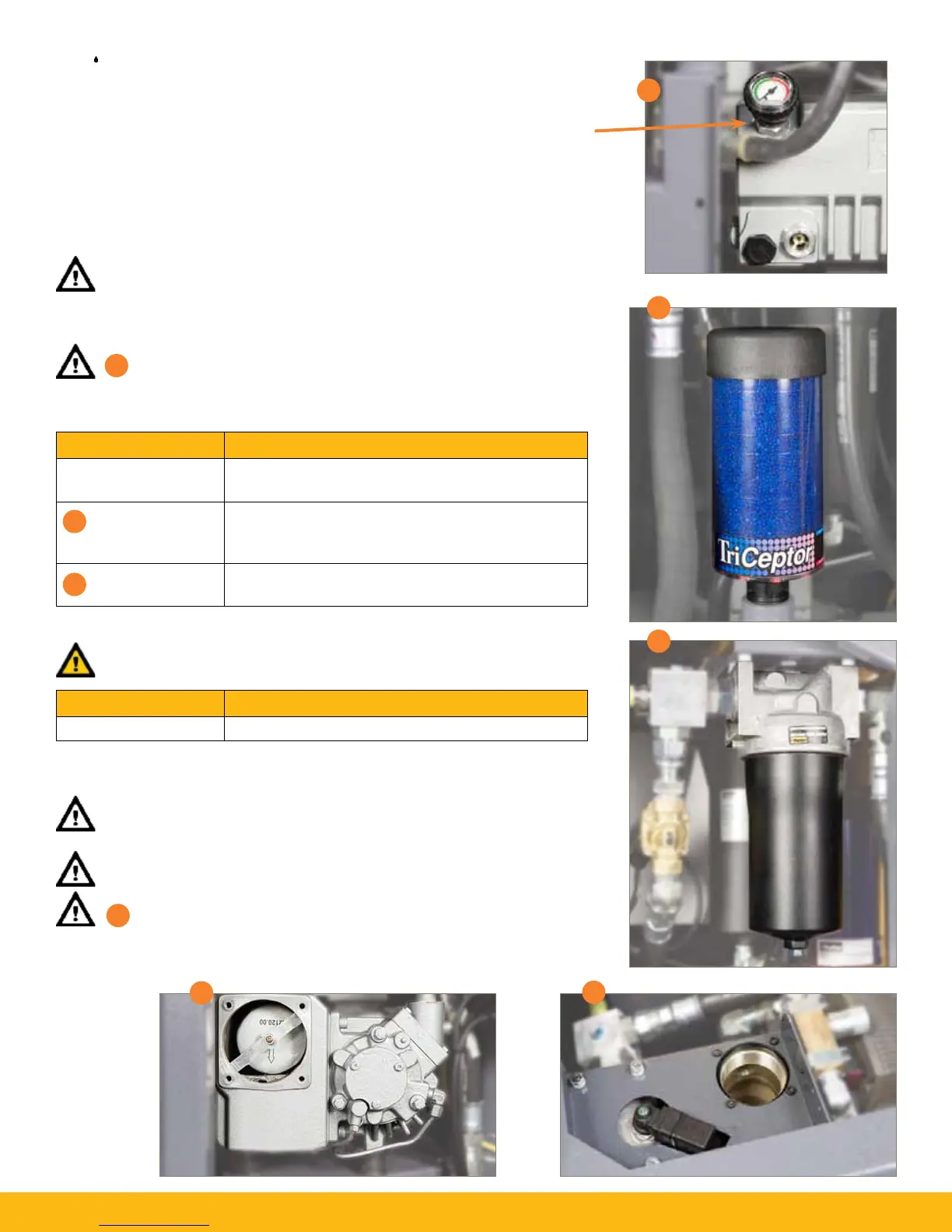

2 Air breather

Check the breather. Normal color will be blue. If

the color is pink, the desiccant is saturated with

moisture and needs to be changed.

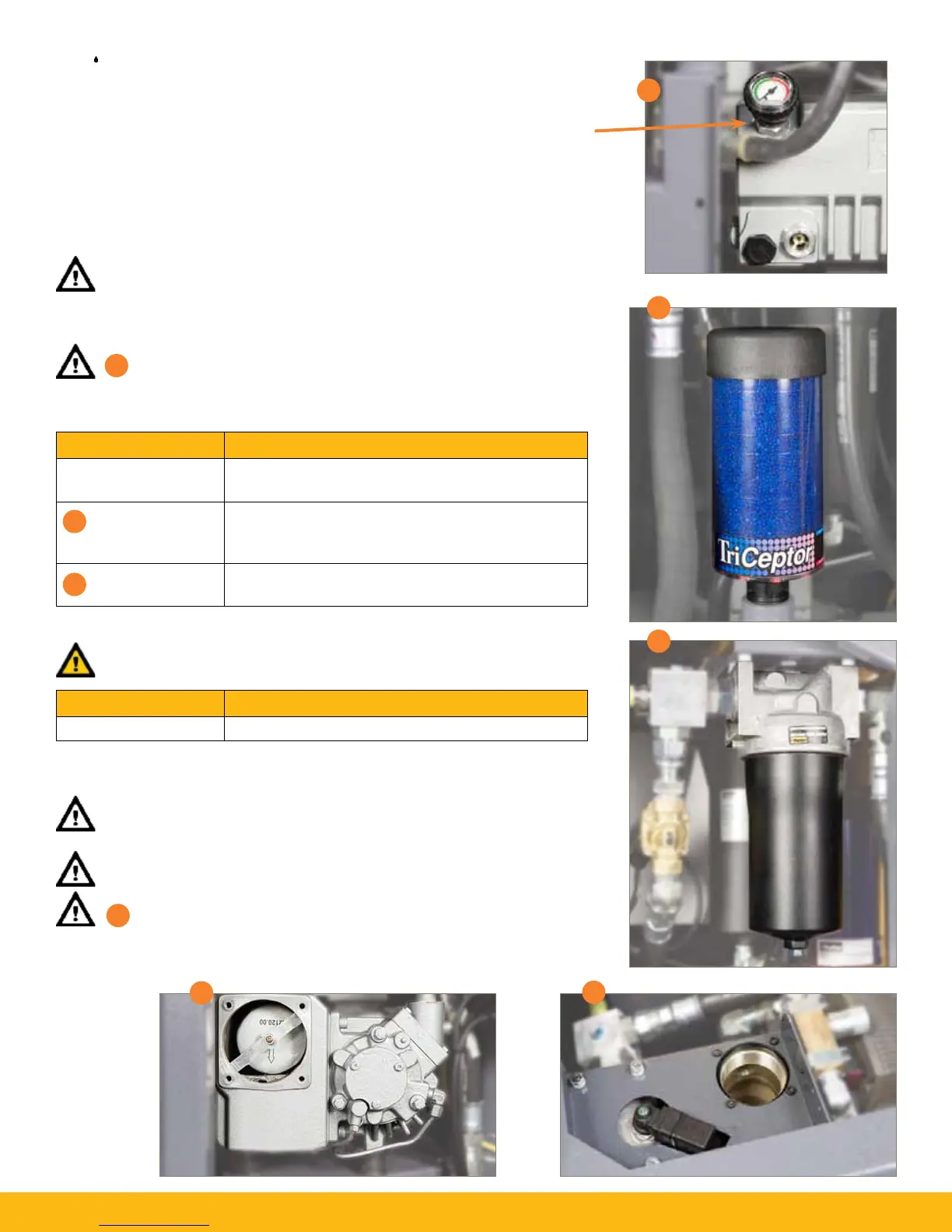

3 Oil filters

Check the filter element condition indicator. If

needed, change the filter element.

Items Inspection Activities

Hoses Check the overall quality of the hoses.

6.3 Maintenance

To ensure proper operation of the system maintenance must be

carried out on a regular basis.

Maintain hydraulic filter according to the ∆P indicator.

(PN 936711Q)

Replace all coalescing filters after 300 hours of use.

(PN 943237)

2

A

3

3

A

B

B

Fill Port

Loading...

Loading...