| User’s Manual

18

9 Troubleshooting

9.1 Safety Precautions

Always wear the prescribed personal protective equipment while working with the Sentinel.

Indicates the alarm will cause an automatic shut down.

See Chapter 2 for more information and safety precautions.

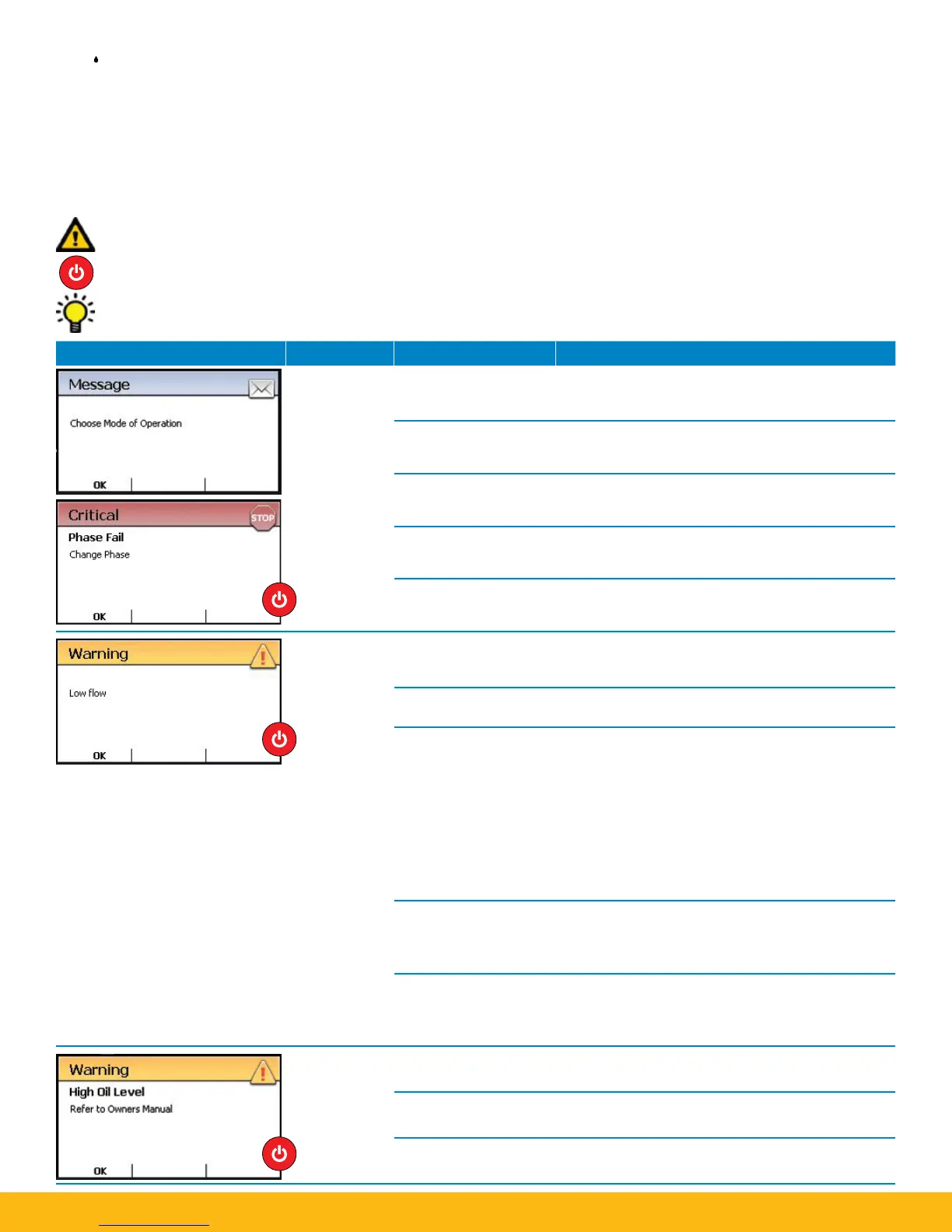

Alarm Image Problem Cause Solution

Unit fails to

run from IQAN

screen

Mode not selected

Choose mode of operation before pressing “On/Off”.

Phase Fail Are you out of phase?

High Sump See “Oil in Sump” warning.

Vacuum Overow See “High Oil Level” warning.

High Ambient Temp See “High Ambient Temp” warning.

Low Flow Inlet obstructed or

pinched hose

Straighten or replace. Check any ltration placed

before the Sentinel for blockage. Check all isolation

valves.

Inlet Valve Check solenoid on the inlet valve to make sure it is

functioning.

Low vacuum level,

should be greater than

22 in/HG (558 mm)

Check vacuum pump for proper operation.

Check for leaks by shutting off oil inlet valve, closing

air inlet valve to vacuum chamber, manually operate

unit until vacuum gage reads 25 in/HG, and then

stop unit. If vacuum holds for less than 30 sec then

a leak is present. If 22 in Hg cannot be achieved

and no leak is detected then check the vacuum

pump for proper function adjust or replace parts as

required.

Check needle valve, adjust for altitude.

Improper PVS installa-

tion, negative head too

high for unit

Check specication sheet. Maximum negative

suction head is 8 ft. (2438 mm). Increase inlet hose

diameter and shorten hose length to reduce line

pressure loss. Preheat oil to reduce viscosity.

Use of quick discon-

nect on inlet hose.

Quick disconnects are not recommended. Replace

with standard “full port” valve or increase size of

quick disconnect to 1.5 times the diameter of inlet

hose or consult factory for other options.

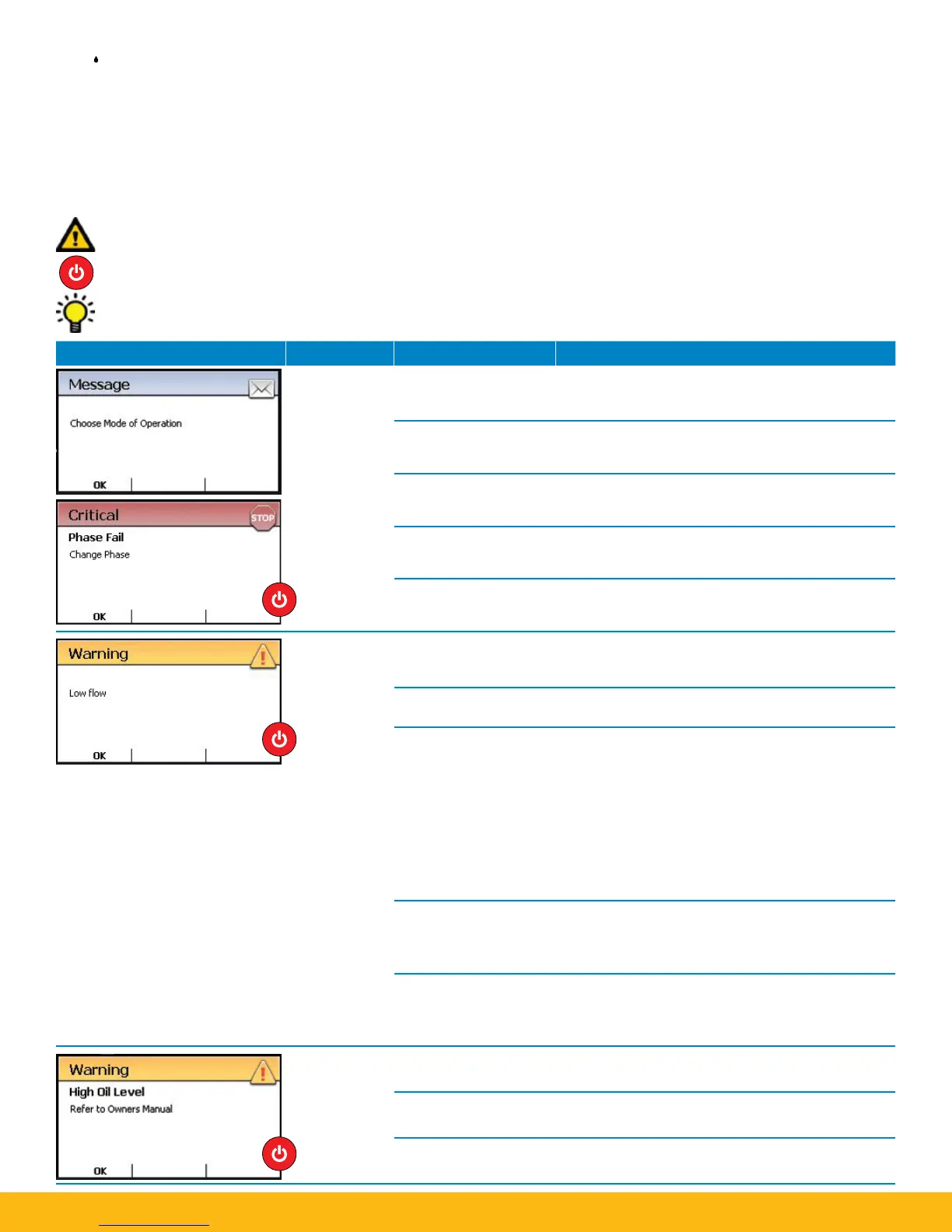

High Oil Level Inlet control valve not

closing

Check inlet control valve for debris caught in the

diaphragm. If problem persists, install a suction filter.

Middle oat switch

stuck closed

Check oat switch in vacuum chamber.

Air inlet needle valve

closed

Check needle valve and adjust if necessary.

A low flow alarm will be displayed if the

Sentinel does not take in fluid at a rate

quick enough to operate properly

Loading...

Loading...