Onlyqualifiedservicepersonnelshouldperformmaintenanceand

serviceproceduresthatrequireunittopremoval.

Refertothefollowingtopremovalprocedures:

1.Removescrewsonunittopcoversurface.(Saveallscrews.)

2.Removescrewsonunittopcoverflange.(Saveallscrews.)

3.Lifttopfromunitcarefully.Settoponedgeandmakesure

thattopissupportedbyunitsidethatisoppositeduct(or

plenum)side.

4.Carefullyreplaceandsecureunittoptounit,usingscrews

removedinSteps1and2,whenmaintenanceand/orservice

proceduresarecompleted.

Step 3 -- Indoor Blower and Motor

For longer life, operating economy, and continuing efficiency,

clean accumulated dirt and grease from the blower wheel and

motor annually.

I

ELECTRICALSHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect and tag electrical power to the unit before

cleaning and lubricating the blower motor and wheel.

To clean the blower wheel:

1. Remove the blower housing:

a. Remove the screws on the external side of the duct

panel that fasten the housing to the duct panel assembly.

b. Remove the side access panel and unscrew the

mounting bracket that fastens the blower housing to the

internal partition panel fo the control box assembly.

c. Make sure that the blower housing is supported by hand

before completely removing the mounting bracket.

d. Slide the blower housing from the rails of the duct panel

and place it outside the unit.

2. Remove the blower wheel from the housing:

a. Loosen the set screw which secures the wheel to the

motor shaft.

b. Loosen the three mounting legs of the motor by

removing the bolts that fasten themounting legs to the

housing.

c. Slide out the motor assembly (motor, belly band and the

3 mounting legs) from the hub of the wheel.

d. Remove the filler panel at the discharge end of the

blower housing by removing the two screws that fasten

it to the housing.

e. Remove the wheel form the housing.

3. Remove the caked on dirt from the wheel and the motor

using a brush.

4. Remove lint and dirt accumulations from the wheel and

housing with a vacuum cleaner, using a soft brush

attachment.

5. Remove grease and oil with a mild solvent.

6. Reassemble

a. Slip the wheel back in the housing with the hub set

screw parented in the correct direction.

b. Install the filler panel.

c. Reinsert the motor assembly in the wheel hub and align

the mounting legs with the housing mounting hold

locations.

d. Tighten the mounting bolts to fasten the motor assembly

with the housing.

e. Center the wheel in the housing by sliding it, align the

flat end of the shaft with the set screw and tighten the

set screw.

f. Slide back the blower housing into the mounting rails in

the duct panel and install the mounting bracket back in

its position.

g. Install the screws on the external side of the duct panel

to fasten duct panel with the housing.

h. Replace the side access panel.

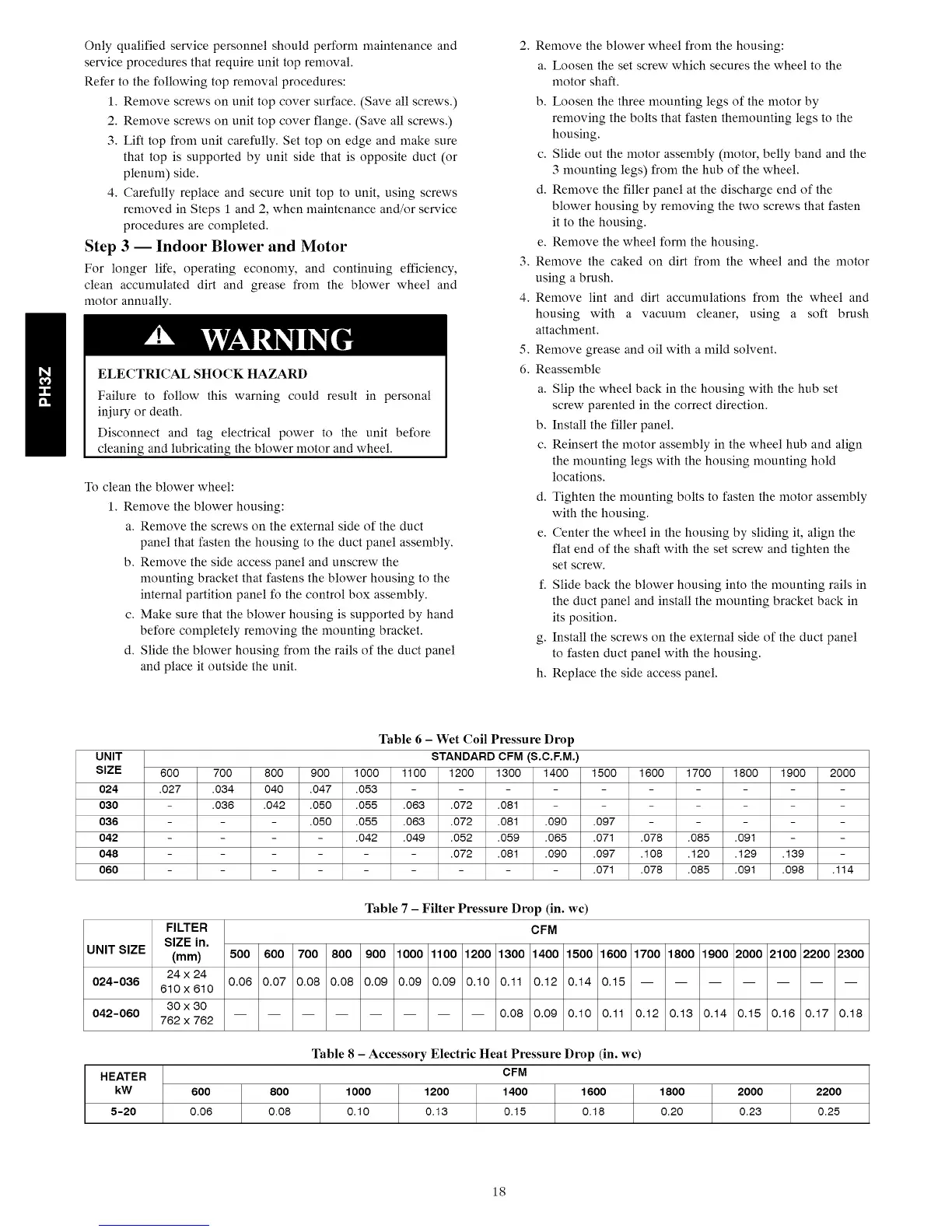

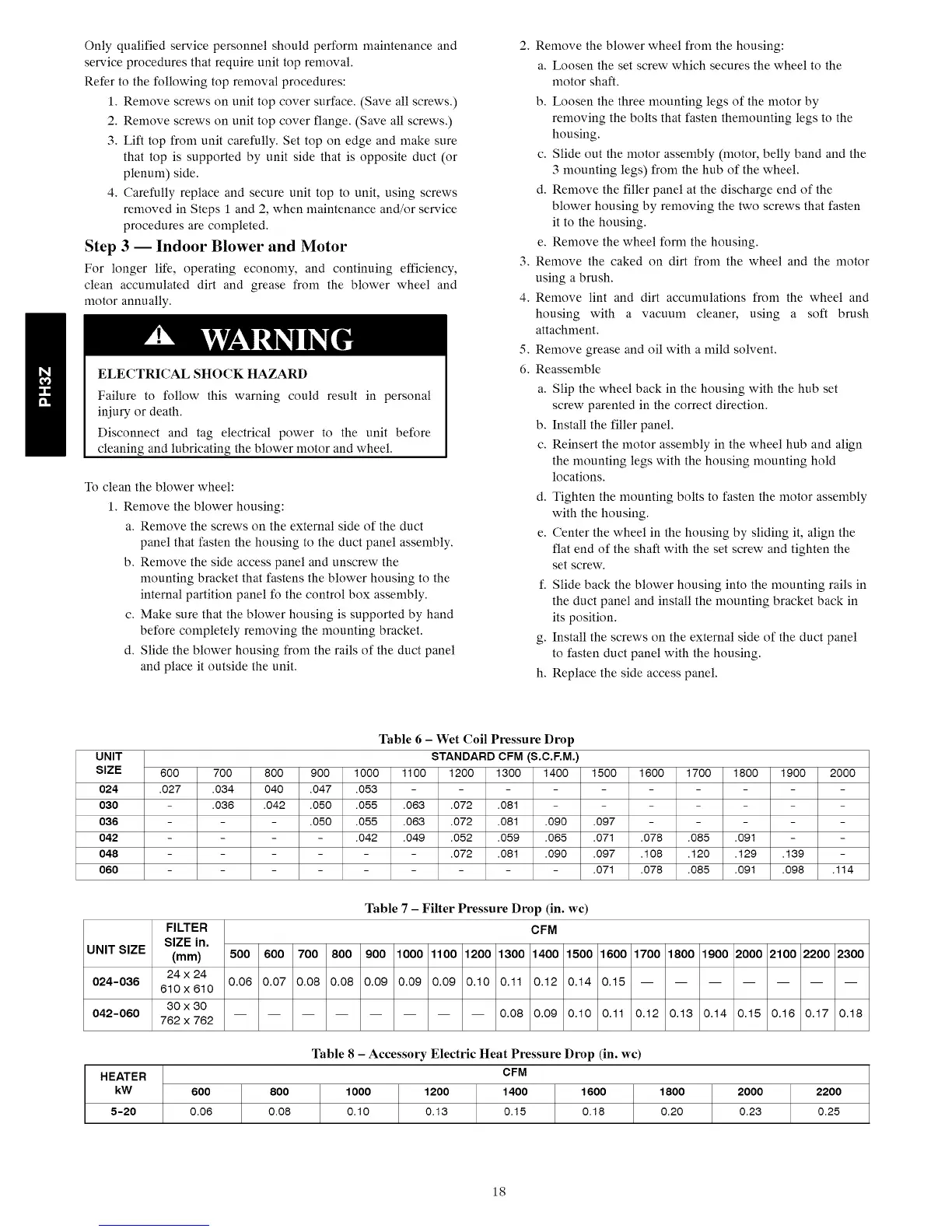

Table 6 -Wet Coil Pressure Drop

UNIT STANDARD CFM (S.C.EM.)

SIZE 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

024 .027 .034 040 .047 .053 - - -

030 .036 .042 .050 .055 .063 .072 .081 - -

036 - - .050 .055 .063 .072 .081 .090 .097 - -

042 - - .042 .049 .052 .059 .065 .071 .078 .085 .091

048 .... .072 .081 .090 .097 .108 .120 .129 .139

060 .... .071 .078 .085 .091 .098 .114

UNIT SIZE

024-036

042-060

FILTER

SiZE in.

(mm)

24 x 24

610 x 610

30 x 30

762 x 762

500 600

0.06 0.07

Table 7 - Filter Pressure Drop (in. wc)

CFM

700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300

0.08 0.08 0.09 0.09 0.09 0.10 0.11 0.12 0.14 0.15

0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.16 0.17 0.18

Table 8 - Accessory Electric Heat Pressure Drop (in. wc)

HEATER CFM

kW 600 800 1000 1200 1400 1600 1800 2000 2200

5-20 0.06 0.08 0.10 0.13 0.15 0.18 0.20 0.23 0.25

18

Loading...

Loading...