50

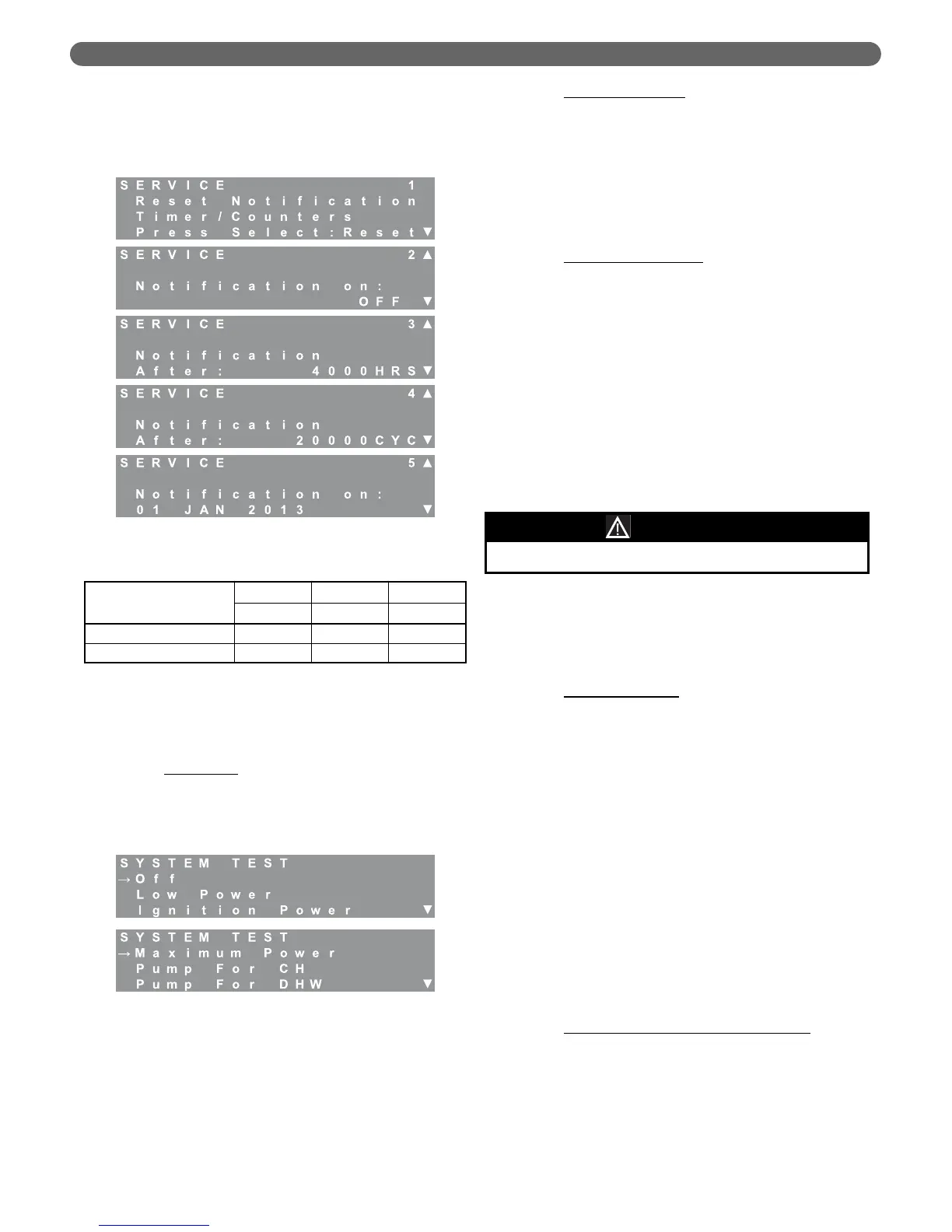

If desired, the installer can select a specific date for the

Service Notification. Simply press the “Select” key

when viewing the “Notification on:” date screen. Use

the “M” and “L” keys to set the value. Pressing

“Select” activates the next date parameter.

7. System Test

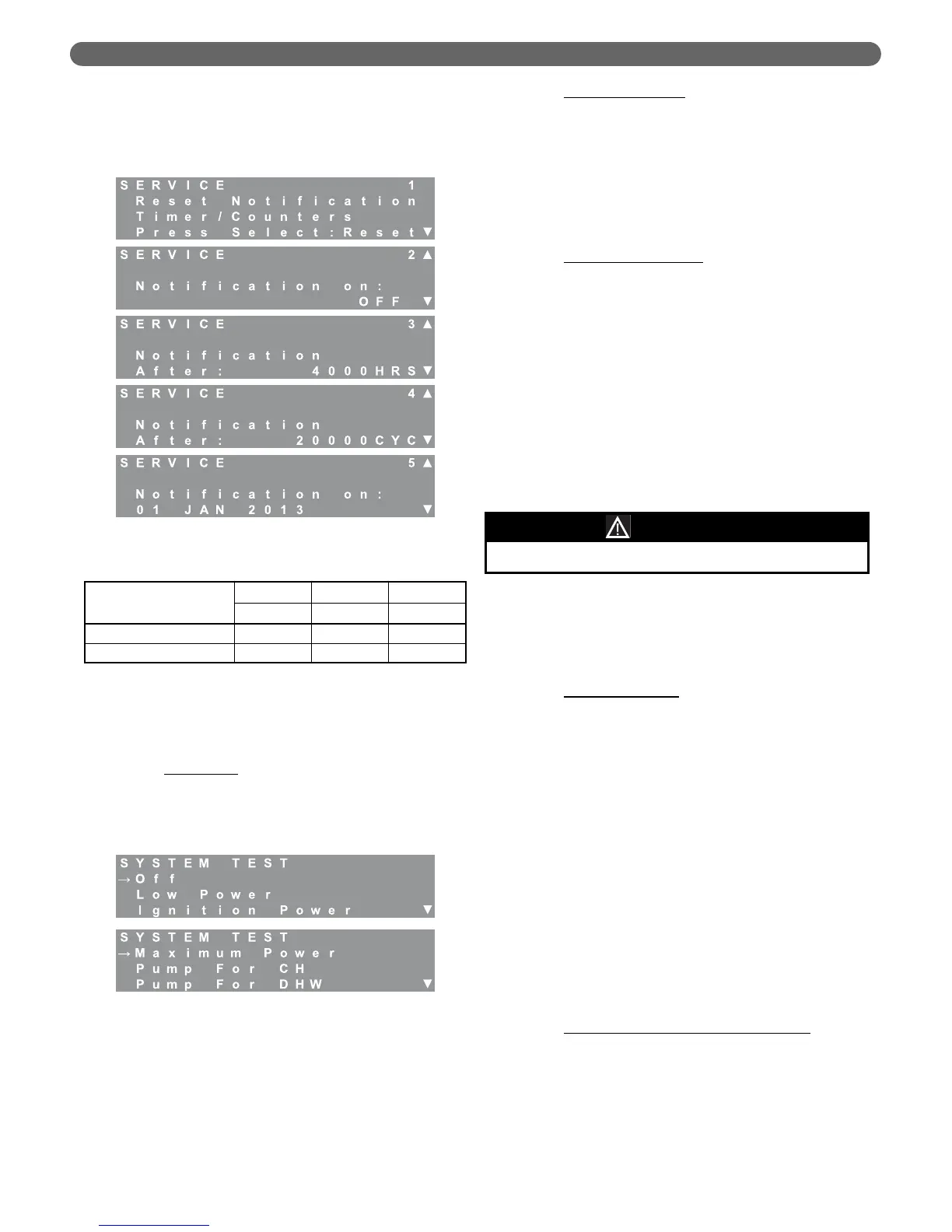

System Test settings allow the installer or service

person to operate each burner manually at it

maximum, minimum and ignition rates. The following

outlines the system test operation.

a. Burner Only

:

•

Eliminate all heat demands to the boiler by

disconnecting the CH thermostat from terminals

#1 & #2 and disconnecting the DHW sensor

or thermostat from terminals #5 & #6.

•

Use the “M” and “L” keys to position the

arrow at the desired power setting.

•

Press select to activate System Test. The

burner will ignite and then operate at the

selected input rate until “Off” is selected from

the System Test menu or for 1 hour. The

burner may cycle off on limit if the input rate

exceeds the heating load.

b. Pump For CH/DHW

:

•

This function can be used to check the function

of the CH and DHW circulating pump outputs.

•

While in “Standby”, choose the desired pump

output from the Installer Menu, System Test

screen on the display.

•

The pump terminals should be activated. If the

pumps don’t appear to be operating, check the

voltage on the pump output terminals.

c. Multiple Boiler Systems

:

•

These selections may also be used in a

multiple boiler, cascade system when testing a

dependent burner.

•

In multiple boiler systems, these pumps are to

be connected to the master boiler in the

cascade. Therefore, when a dependent boiler

is being tested, there will not likely be sufficient

heating load to run the boiler for very long.

•

In this case. Choose “Pump For CH” or

“Pump for DHW” from the System Test menu

on the display of the managing boiler in the

system before running the dependent boilers.

8. Sequence (Managing Burner Display Only)

Adjustments in the sequence menu affect the

sequence of burner operation. The first six parameters

will stop and start burners as follows:

a. On a call for heat (either CH or DHW) the 1st

burner will start. The 1st burner can be either the

managing or dependent burner based on the

Rotation Interval

chosen.

b. After the 1st burner is activated, the 2nd burner will

come on if all three of the following conditions are

met:

i. Supply Temperature < Target Temperature –

Start Burner Differential

ii. 1st Burner Input Rate > Next Burner Start

Rate

iii. Start Delay Time has elapsed (Time from

when both prior parameters are met)

c. The 2nd burner will be deactivated if the following

conditions are met:

i. Supply Temperature > Target Temperature +

Stop Burner Differential

ii. Both Burner Input Rates < Next Burner

Stop Rate

iii. Stop Delay Time has elapsed (Time from

when both prior parameters are met)

d. Calculated Setpoint Max Offset Up/Down

: The

target supply temperature of both burners are

adjusted if the system supply temperature is above

or below the targeted value. For example, if the

system supply target temperature is 150°F, each

burner will target this temperature. However, if

they approach their individual target temperature

before the system supply approaches its target, a

temperature offset is applied. This offset is

Figure 8.44: Service Notification

Table 8.31: Service Notification Ranges & Defaults

Notification On

Minimum Default Maximum

OFF OFF ON

Hours 0 4,000 8,000

Cycles 0 50,000 20,000

Figure 8.45: System Test Menu

The following features are non-functional for the PFC-460.

NOTICE

BOILER CONTROL: OPERATION

Loading...

Loading...