56

b. Before starting the Lead boiler, the Master control

will first check to be sure that the System

temperature is lower than the System Setpoint +

Stop Boiler Differential

.

c. After a Trial For Ignition (TFI), the lead boiler will

modulate its input rate to meet the heat demand.

d. Any time that a boiler is started the Cascade Start

Delay Time will be initiated and no boiler will be

allowed to start before this time elapses. This is to

allow time for the system to stabilize before

bringing on an additional boiler.

e. After the delay time has elapsed, one of the

following conditions must be met before starting

the next boiler:

• The System Temperature must be lower than

the Set Point minus the Cascade Start Boiler

Differential temperature, or

• The input rate of all boilers operating must be

higher than the Next Boiler Start Rate

.

f. After operation of the second boiler is initiated,

the Cascade Start Delay Time

must elapse before

bringing on additional boilers. Again, in order to

initiate operation of additional boilers one of the

same conditions must be met.

g. When the boiler system approaches its Setpoint,

the boilers will reduce input rates at approximately

equal values. When the input rates of all of the

operating boilers fall below the Next Boiler Stop

Rate, the master control will shut down the last

boiler that started after the Cascade Stop Delay

Time has elapsed.

h. The Calculated Setpoint Max Offset Up

and

Calculated Setpoint Max Offset Down

are applied

to individual boilers in multiple boiler cascade

operation.

• These temperature offset values are used to

change the response of individual boilers to

the system setpoint.

• Increasing these values will cause the system

to react more quickly, but may result in

frequent cycling.

• Decreasing these values will cause the system

to react more slowly to achieve the setpoint.

• By increasing the Calculated Setpoint Max

Offset Up value, the Master boiler will offset

individual boiler setpoints temperature by a

larger amount in order to achieve the system

setpoint.

• By increasing the Calculated Setpoint Max

Offset Down value, the boilers will decrease

the boiler setpoints by a larger amount to

achieve the system setpoint.

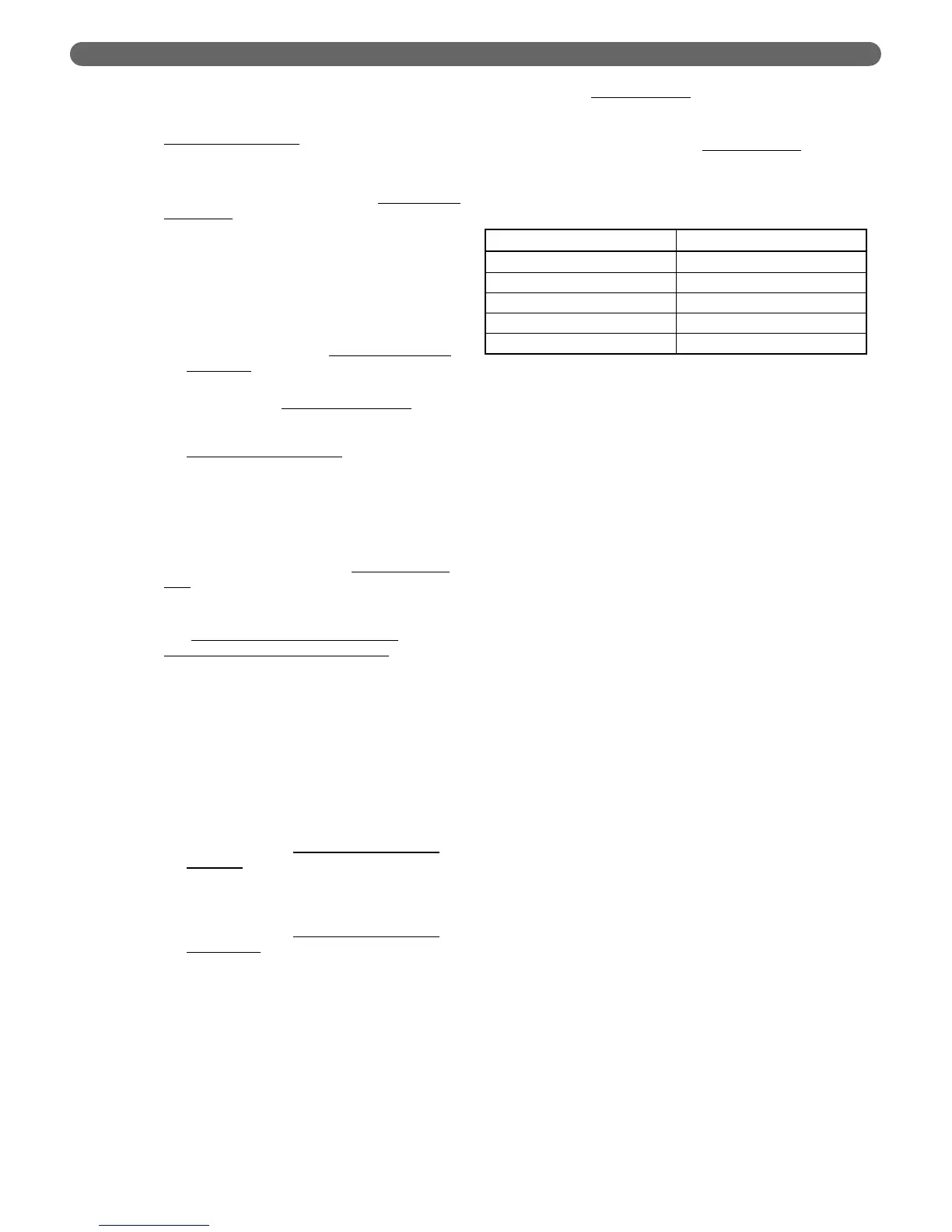

i. The Rotation Interval

is the frequency at which the

Master Boiler will change the Lead boiler in the

sequence.

• For example, if the Rotation Interval

is set

to 4 days and there are 4 boilers operating

together, the following chart shows the

operating sequence over the next 25 days.

6. Multiple Boilers – Boost & Warm Weather

Shutdown (WWSD):

a. To use the Boost function with multiple boilers, the

parameters on the master boiler are used. Boost

parameters set on dependent boilers have no

effect on the system operation.

b. Similarly, the WWSD Temperature set on the

master boiler will prevent any boilers from

operating for a CH demand when the outdoor

temperature is above this value.

7. Multiple Boilers – Ramp Delay:

a. The ramp delay feature can be set on each

individual boiler.

b. However, it is important to note that since the

dependent boilers treat DHW demands as a CH

call, the ramp delay will take effect even when the

DHW tank calls.

8. Multiple Boilers – Anti-Cycling:

a. The Anti-Cycling feature is active on all boilers

unless it is disabled.

b. This will prevent dependent boilers from operating

within the prescribed time limit. However, it will

only prevent the boiler from cycling on its own

limit. Repetitive calls from the master boiler will

result in cycling.

9. Multiple Boilers – DHW Operation:

a. Since the DHW tank sensor or thermostat is

connected only to the Master boiler, this is the

only boiler that will receive the DHW demand.

b. The master control will start boilers as necessary

to meet the demand.

c. Boilers with a boiler address of 2 or higher will

automatically be switched to DHW Mode 0 (No

DHW).

Table 8.34: Rotation Interval Sequence

Days of Operation Start/Stop Sequence

1-5 1-2-3-4

6-10 2-3-4-1

11-15 3-4-1-2

16-20 4-1-2-3

21-25 1-2-3-4

BOILER CONTROL: OPERATION

Loading...

Loading...