31

■ MAINTENANCE

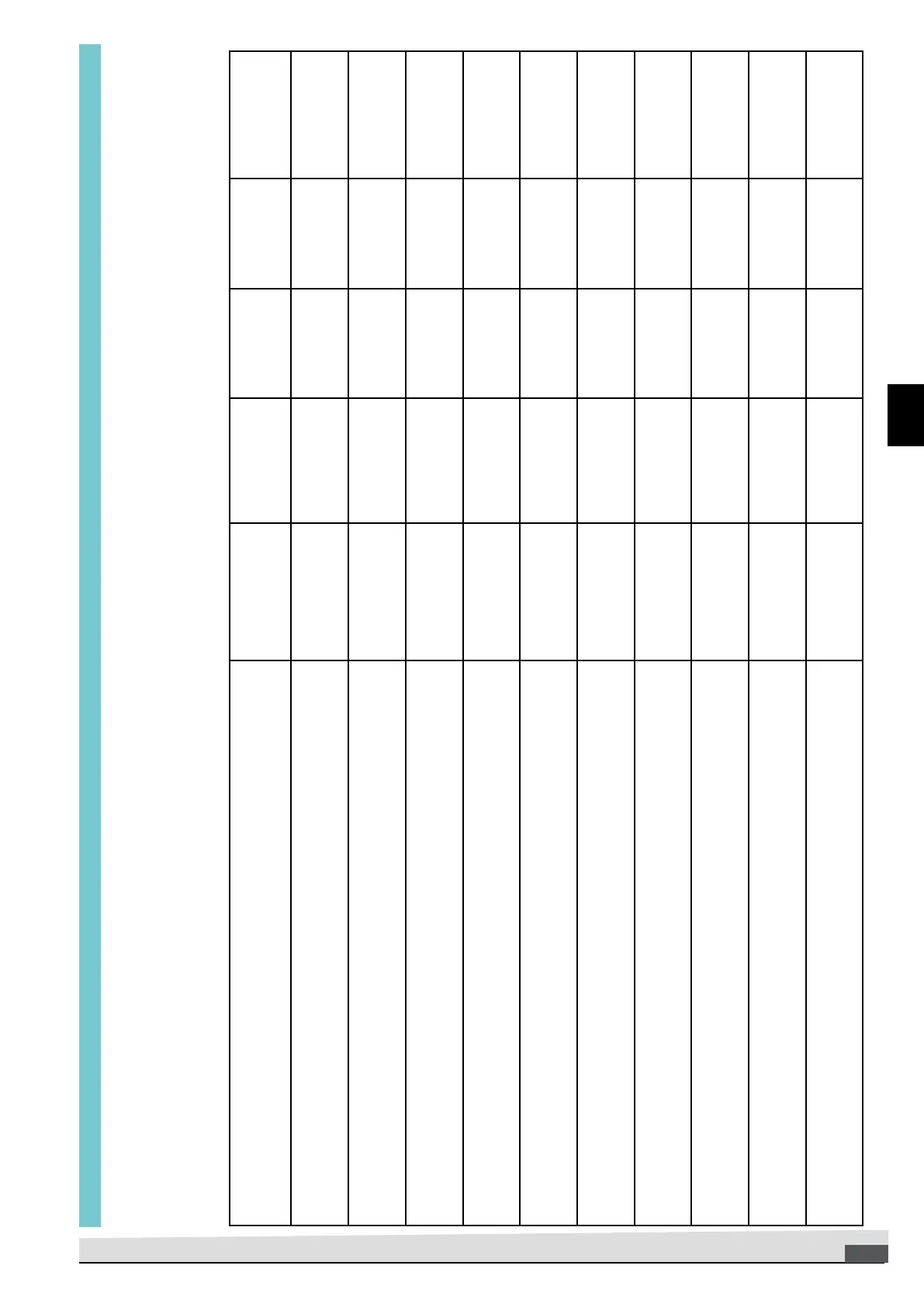

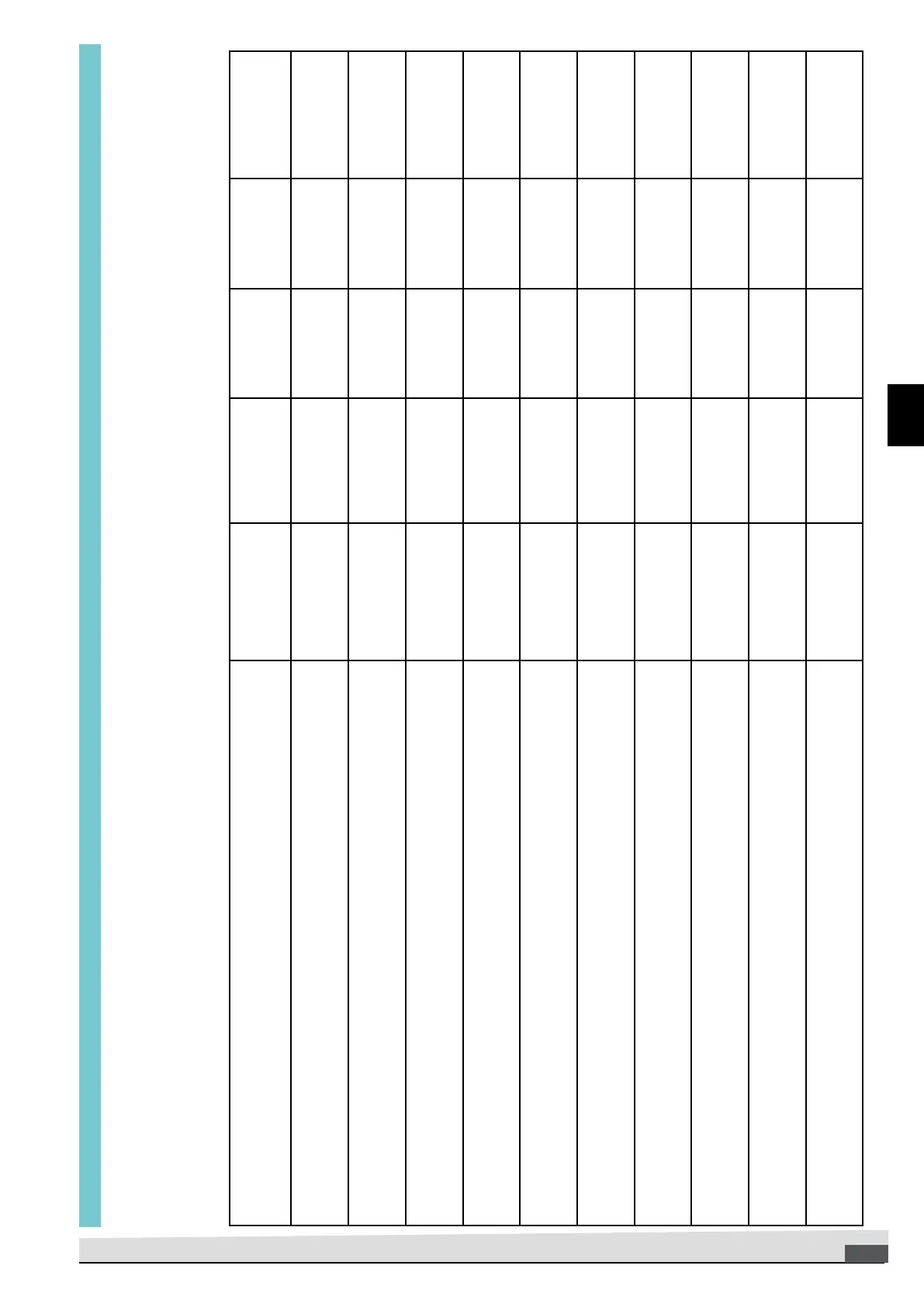

Every year or as

necessary

X

X

X

X

X

After use

X

X

Every month

X

X

Every two hours

X

X

X

At each start-up

X

X

X

X

X

X

X

Maintenance task

Cleaning the Excelion 2000 Professional brush cutter (no high-pressure cleaner

but by blasting or brushing)

Visual verication of the machine's safety devices (carrying plate, safety guard,

angle transmission)

Verication of the functioning of the trigger safety

Sharpening verication and re-sharpening if necessary

Visual inspection of the cutting tool (absence of cracks or distortion)

Visual inspection of the cutting tool's attachment to the shaft (absence of distortion

or wear and tear)

Verication of the wear and tear of the notched cam teeth and sharpening if

necessary or replacement of the notched cam

Check the battery level

Machine check by an approved Pellenc dealer

Angle transmission lubrication

NOTE:

Have your machine serviced every 400 hours or at least once a year by a Pellenc approved distributor.

Always store the tool clean and in a dry place, with the battery charged.

Loading...

Loading...