3.6 Flowmeters and Controls

3.6.1 All models

The flowmeters, mounted behind the perspex

cover on the left hand side of the machine, are

length-indexed to prevent inadvertent, incorrect

installation.

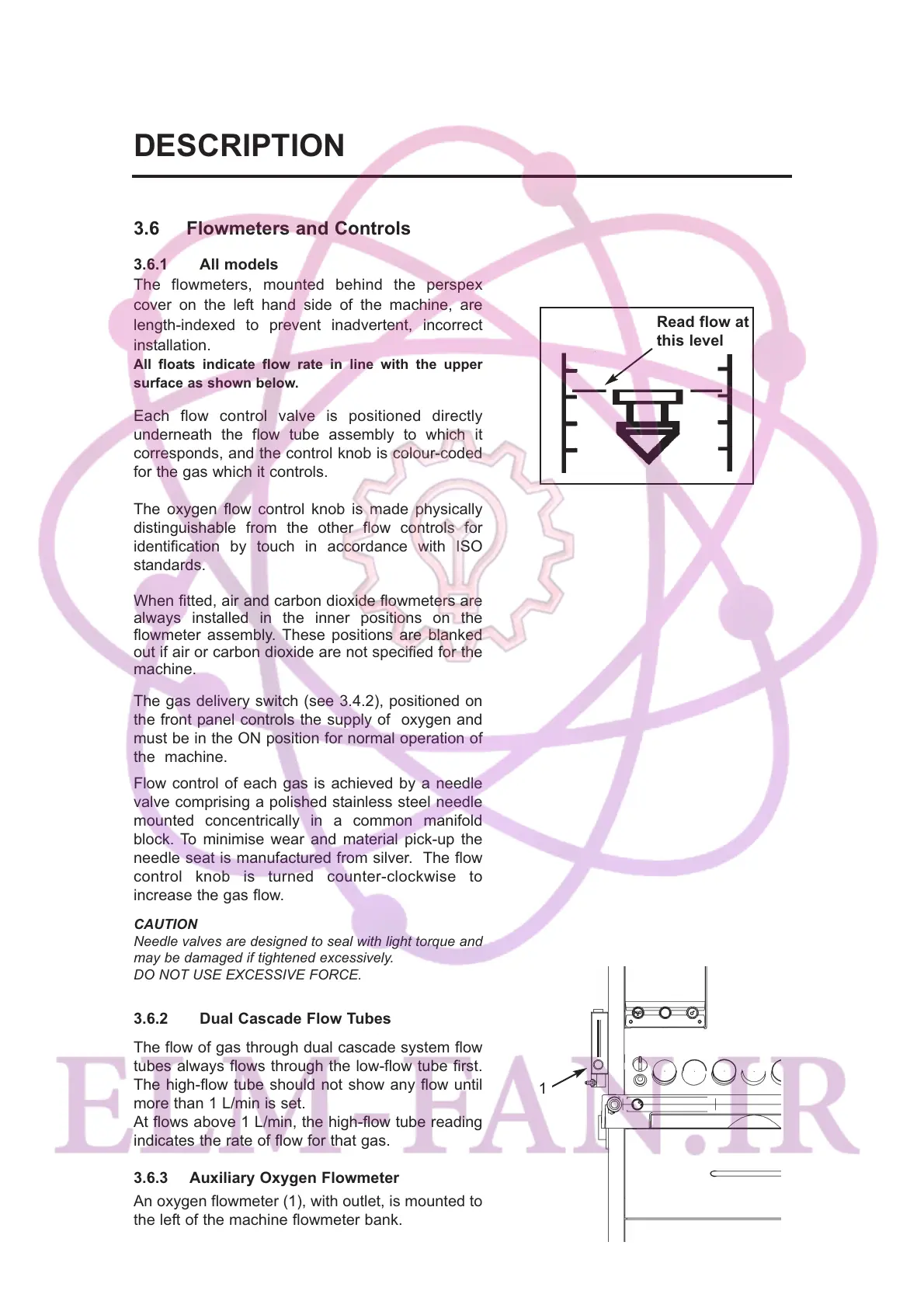

All floats indicate flow rate in line with the upper

surface as shown below.

Each flow control valve is positioned directly

underneath the flow tube assembly to which it

corresponds, and the control knob is colour-coded

for the gas which it controls.

The oxygen flow control knob is made physically

distinguishable from the other flow controls for

identification by touch in accordance with ISO

standards.

When fitted, air and carbon dioxide flowmeters are

always installed in the inner positions on the

flowmeter assembly. These positions are blanked

out if air or carbon dioxide are not specified for the

machine.

The gas delivery switch (see 3.4.2), positioned on

the front panel controls the supply of oxygen and

must be in the ON position for normal operation of

the machine.

Flow control of each gas is achieved by a needle

valve comprising a polished stainless steel needle

mounted concentrically in a common manifold

block. To minimise wear and material pick-up the

needle seat is manufactured from silver. The flow

control knob is turned counter-clockwise to

increase the gas flow.

CAUTION

Needle valves are designed to seal with light torque and

may be damaged if tightened excessively.

DO NOT USE EXCESSIVE FORCE.

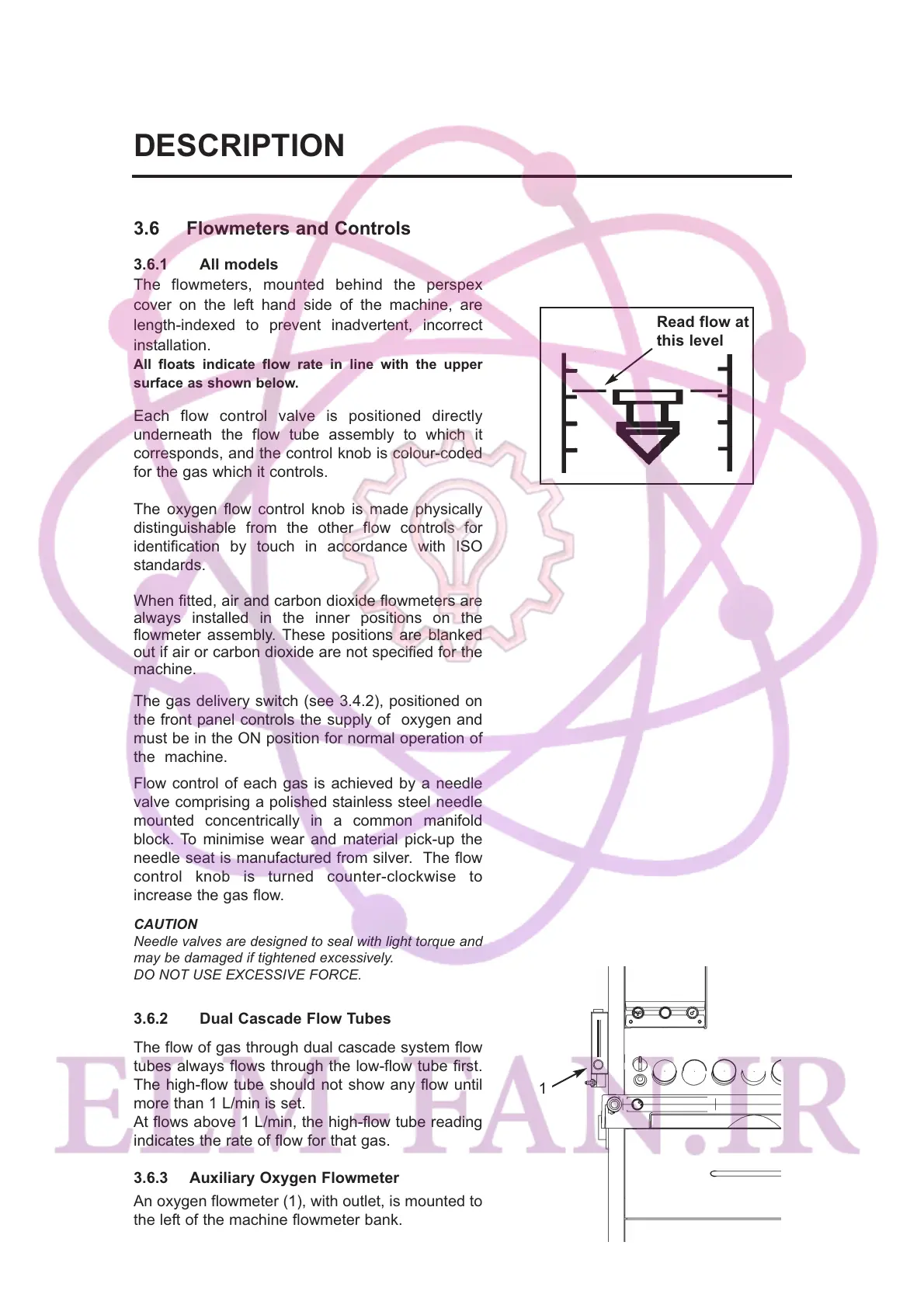

3.6.2 Dual Cascade Flow Tubes

The flow of gas through dual cascade system flow

tubes always flows through the low-flow tube first.

The high-flow tube should not show any flow until

more than 1 L/min is set.

At flows above 1 L/min, the high-flow tube reading

indicates the rate of flow for that gas.

3.6.3 Auxiliary Oxygen Flowmeter

An oxygen flowmeter (1), with outlet, is mounted to

the left of the machine flowmeter bank.

9

DESCRIPTION

Read flow at

this level

1

Loading...

Loading...