NOTE: Before turning on the water to the valve, rotate the

two handles on the bypass valve 2-3 times. This

will help seat O-rings and prevent leaking.

To remove a clip:

1. Turn off water and release water pressure at the valve.

2. Push the water line connectors into the bypass and valve.

This will help release O-rings that may have seated in

place.

3. Remove the clip by inserting a at blade under the top

center of the clip and lifting (prying up) (Figure 7 Connector

Assembly).

Do not use pliers to remove a clip. It is likely

the clip will break.

Drain Line Connection

NOTE: Standard commercial practices are expressed here.

Local codes may require changes to the following

suggestions. Check with local authorities before

installing a system.

1. The unit should be above and not more than 20 feet (6.1 m)

from the drain. Use an appropriate adapter tting to connect

1/2-inch (1.3 cm) plastic tubing to the drain line connection

of the control valve.

2. If the unit is located 20-40 feet (6.1-12.2 m) from drain, use

3/4-inch (1.9 cm) tubing. Use appropriate ttings to connect

the 3/4-inch tubing to the 3/4-inch NPT drain connection on

valve.

3. The drain line may be elevated up to 6 feet (1.8 m)

providing the run does not exceed 15 feet (4.6 m) and

water pressure at the softener is not less than 40 psi (2.76

bar). Elevation can increase by 2 feet (61 cm) for each

additional 10 psi (.69 bar) of water pressure at the drain

connector.

4. Where the drain line is elevated but empties into a drain

below the level of the control valve, form a 7-inch (18-cm)

loop at the far end of the line so that the bottom of the loop

is level with the drain line connection. This will provide an

adequate siphon trap.

Where the drain empties into an overhead sewer line, a

sink-type trap must be used.

NOTE: The drain line connects to the elbow previously

installed. It is located between the water line

connections at the rear of the valve.

5. Use pliers to expand a clamp. Slide the clamp up one end

of the longer length drain line tubing about 1-2 inches and

release.

6. Push the tubing over the ribbed drain line tting.

7. Expand the clamp and move it up the tube to pinch the tube

to the ftitting.

8. Secure the discharge end of the drain line to prevent it from

moving.

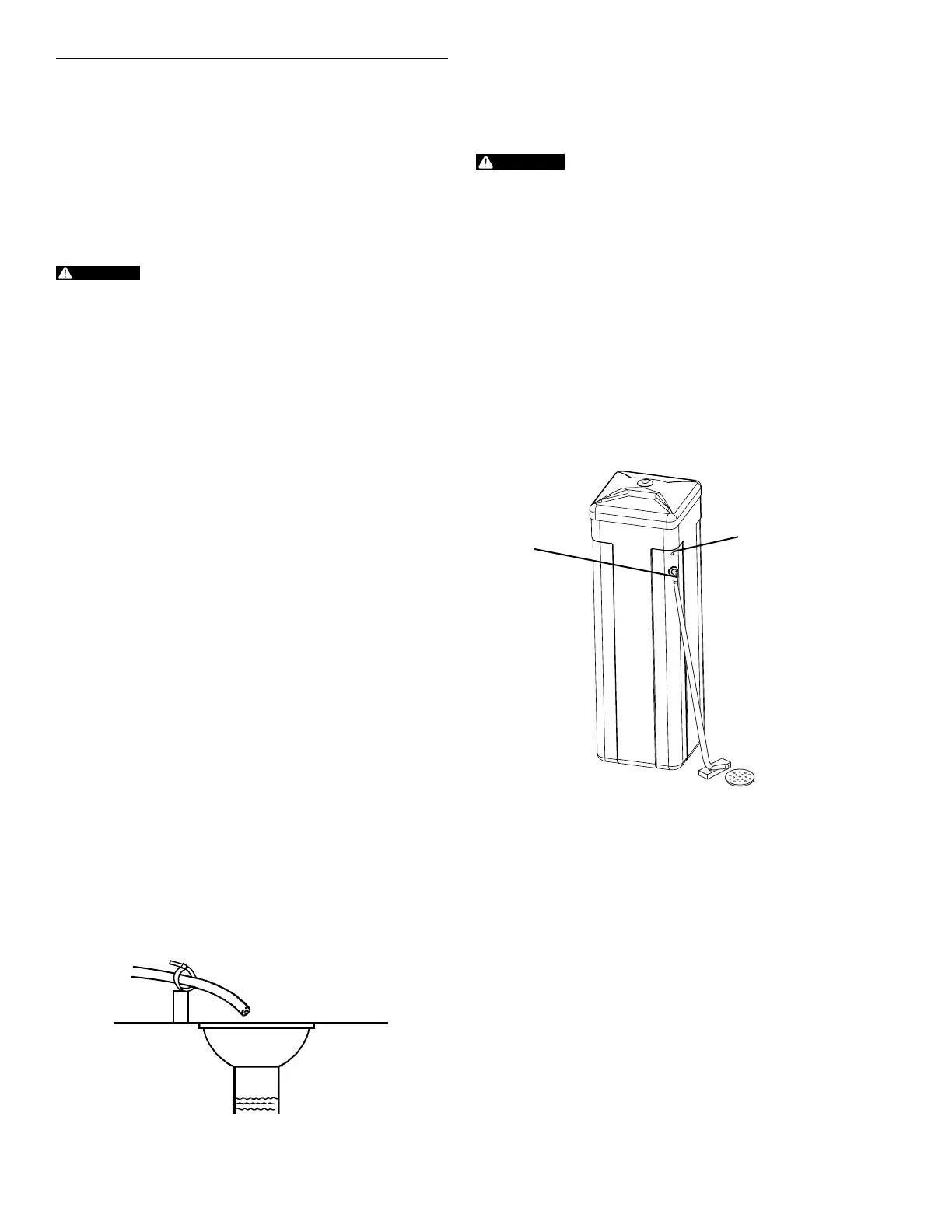

Right Way

Figure 8 Drain Line Connection

NOTE:

Waste connections or drain outlet shall be

designed and constructed to provide for

connection to the sanitary waste system through

an air-gap of 2 pipe diameters or

1 inch (22 mm) whichever is larger.

Never insert drain line directly into a

drain, sewer line, or trap (Figure 8 Drain

Line Connection). Always allow an air gap

between the drain line and the wastewater

to prevent the possibility of sewage being

back-siphoned into the softener.

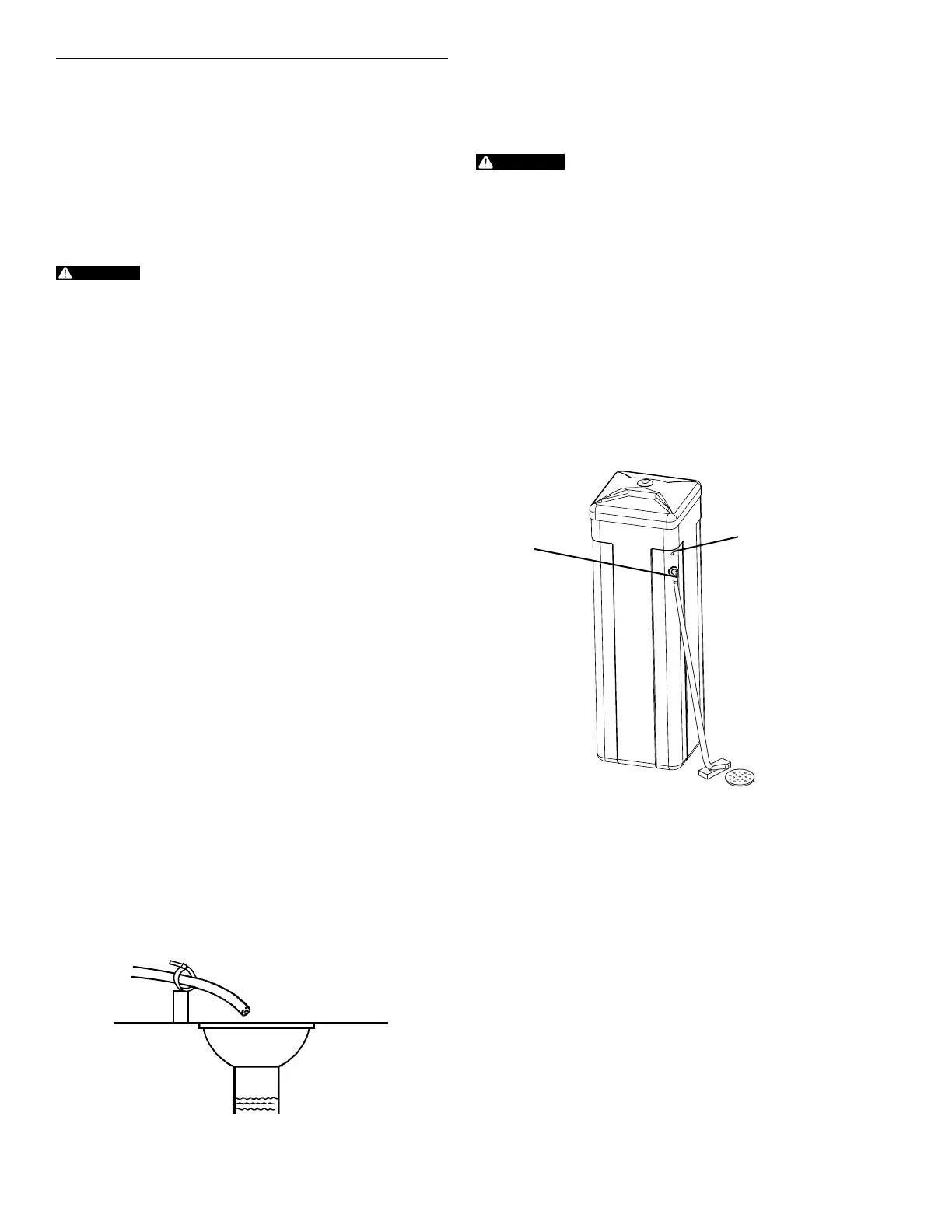

Overow Line Connection

In the event of a malfunction, the salt TANK OVERFLOW will

direct “overow” to the drain instead of spilling on the oor. This

tting should be on the side of the cabinet.

To connect the overow line, locate the tubing connector on the

side of the tank (Figure 9 Tubing Connections). Attach length of

1/2-inch (1.3-cm) I.D. tubing to tting and run to drain. Do not

elevate overow line higher than overow tting.

Do not tie into drain line of control unit. Overow line must be a

direct, separate line from overow tting to drain, sewer or tub.

Allow an air gap as per drain line instructions.

Overow

Connection

Salt Line Opening

Figure 9 Tubing Connections

EQUIPMENT INSTALLATION continued

8 • OM26K

Loading...

Loading...