Electrical Connection

Risk of electric shock. Can shock, burn or

kill. All wiring should be done by a qualified electrician.

• Disconnectpowertopumpbeforeservicing.

• Checkvoltageandphasestampedonpumpmotor

nameplatebeforewiring.Besuretheyagree

withyourelectriccurrentsupply.TheyMUST

be the same. If in doubt, check with your local

powercompany.

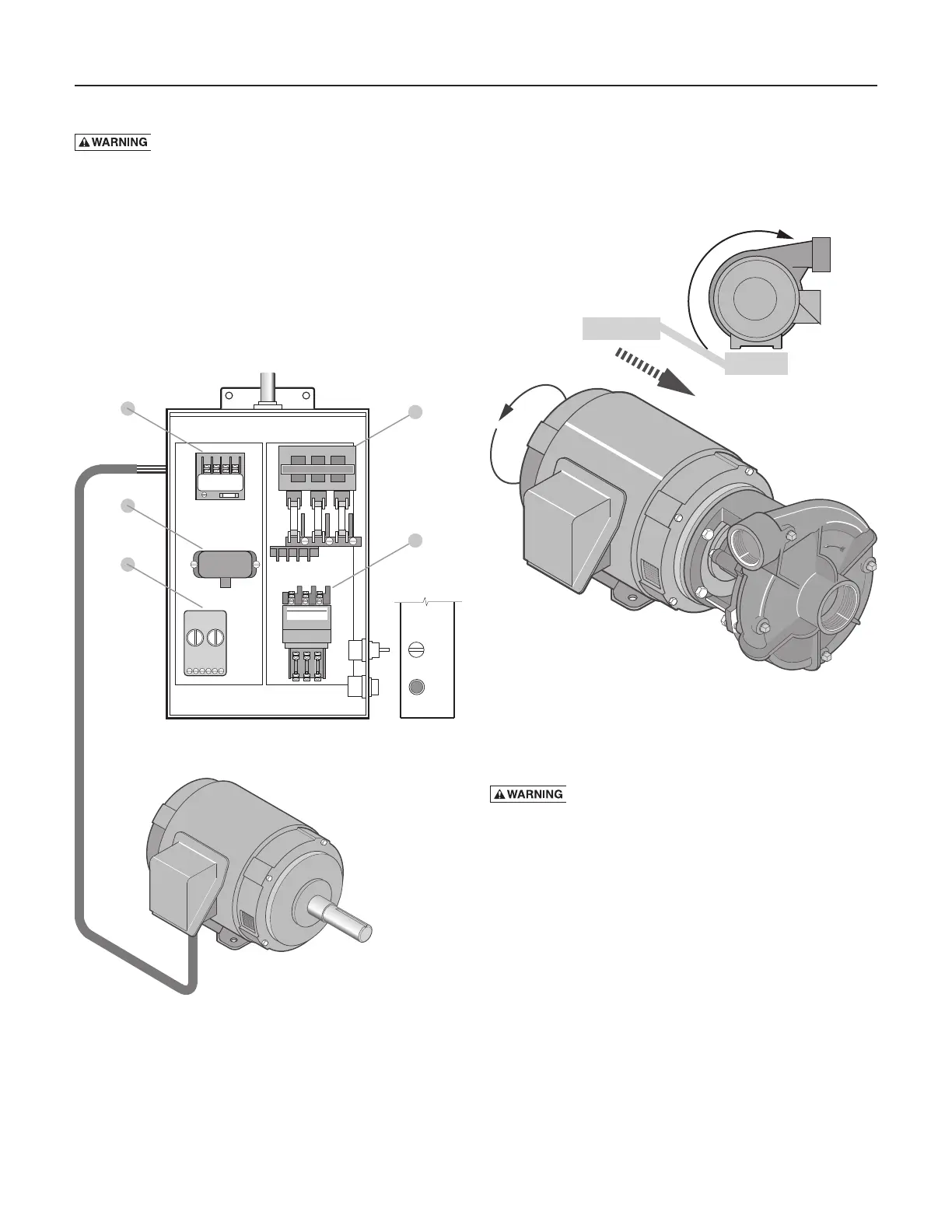

• Refertotheillustrationbelowforminimum

recommended pumping panel components that help

safeguard your pump during operation.

Before Start-Up

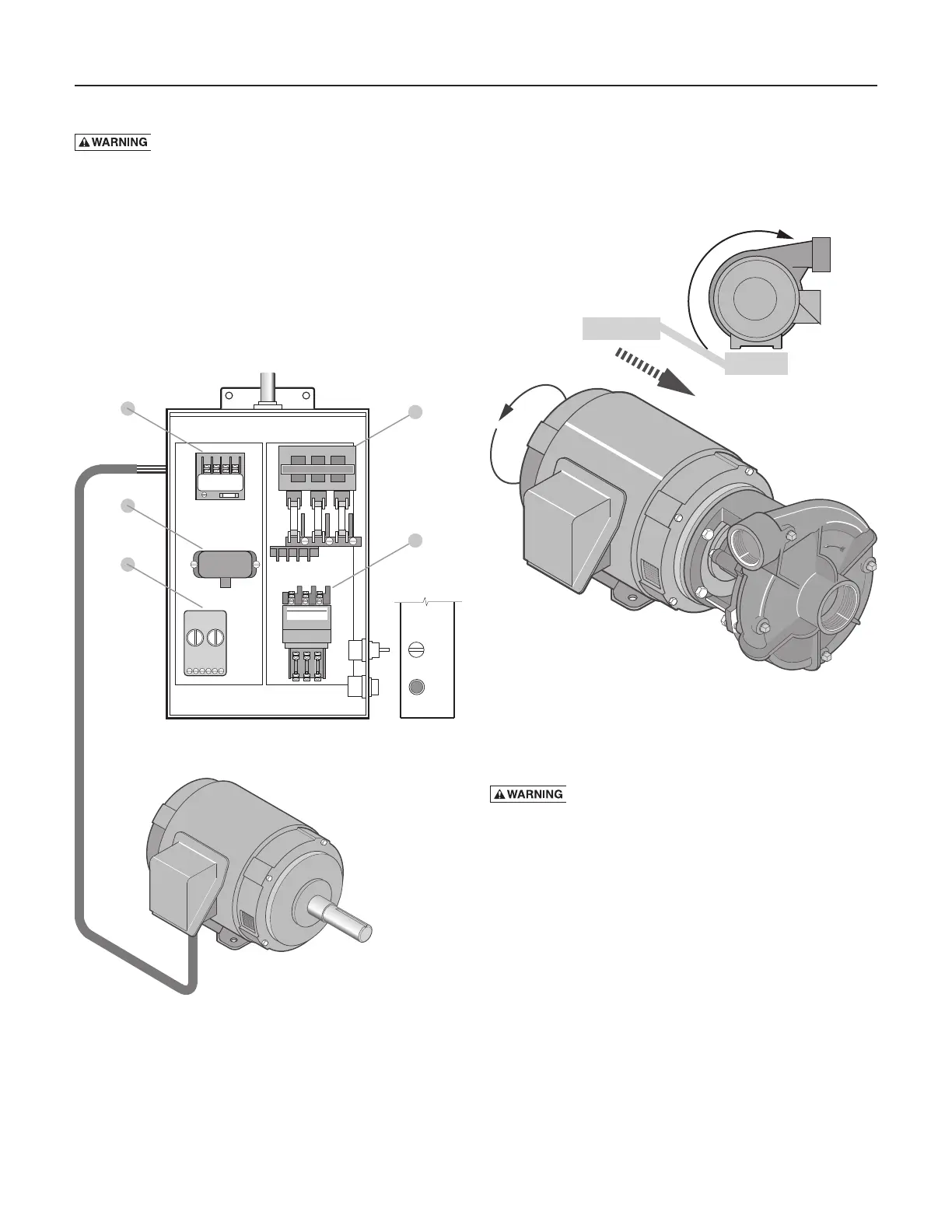

Check Rotation:

Beforepumpisputintooperation,rotationaldirection

must be checked to assure proper performance of pump.

Refertoillustrationshownbelow.

Direction of pump rotation is determined by viewing

liquid end of pump from the back or shaft side, and not

from looking into the impeller eye or front of volute case.

A rotation direction arrow is cast into the pump body

and shows correct rotation.

Risk of electric shock. Can shock, burn or

kill. Disconnect power to pump before servicing. Do not

attempt any wiring changes without first disconnecting

power to pump.

• Single Phase Motors:Refertowiringinformationon

the motor plate to obtain proper rotation.

• Three Phase Motors: If pump runs backwards,

reverse any two leads coming off incoming power

(L1,L2,L3)untilproperrotationisobtained.Reverse

L1andL2,orL2andL3,orL1andL3.

• Pump running backward - Centrifugal pumps

willstillpumpliquids,however,GPMandhead

(discharge pressure) will be a fraction of the

published performance.

NOTICE A motor protection device must be installed for

all three-phase pump motors.

Installation 8

1

2

3

AMP TIME

4

5

L1 L2 L3

AUTO

OFF

HAND

START

Minimumrecommendedcomponentstoprotectyour

pump during operation. Check all local electrical codes

prior to installation.

1 Contactor

2 Lightning Arrestor

3 Loss of Prime Protection

4 Fuseable Disconnect

5 Starter

NEMA 3R Enclosure

3

6

9

12

Engage start switch momentarily (bump motor)

to observe rotational direction.

As viewed.

Viewed from

this direction.

Clockwise rotation

Loading...

Loading...