Maintenance 10

Maintenance

Lubrication

LIQUIDENDofpumprequiresnolubrication.

MOTORbearingsarelubricatedatthefactory.

Re-lubricationatintervalsconsistentwiththeamountof

usewillprovidemaximumbearinglife.Refertomotor

InstructionManualforpropermotorlubricationand

maintenance instructions.

Performance Check

Periodically check the output of the pump. If

performance is noticeably reduced, refer to

Troubleshooting.

Observational Maintenance

When the pump and system operation have been

stabilized, verify that pump unit is operating properly.

Observe the following:

Vibration: All rotating machines can be expected

toproducesomevibration.However,excessive

vibration can reduce the life of the unit. If the

vibration seems excessive, discontinue operation,

determine cause of the excessive vibration,

andcorrect.

Noise: When the unit is operating under load, listen

closely for unusual sounds that might indicate

that the unit is in distress. Determine the cause

andcorrect.

Operating Temperature: During operation, heat is

dissipated from the pump and the driver. After a short

period of time, the surface of the pump bracket will

bequitewarm(ashighas150°F),whichisnormal.

If the surface temperature of the pump bracket or

driver is excessive, discontinue operation, determine

cause of the excessive temperature rise, and correct.

Bearingswillrunhotterforabriefrun-inperiodafter

packing,whichisnormal.However,wornbearings

will cause excessive temperatures and need to be

replaced. The pump unit is cooled by the water

flowing through it, and will normally be at the

temperature of the water being pumped.

Mechanical Seal: Adjustment or maintenance is

normally not required. The seal is enclosed within

the pump and is self adjusting. Seal is cooled and

lubricatedbytheliquidbeingpumped.Referto

Mechanical Shaft Seal section for removal and

replacement information. Do not run pump dry!

Pu mp Protection-Cold Weather/ Wet

Weather Installations

System Drains: Provide drain valves to empty system,

including pump case, to prevent freezing damage.

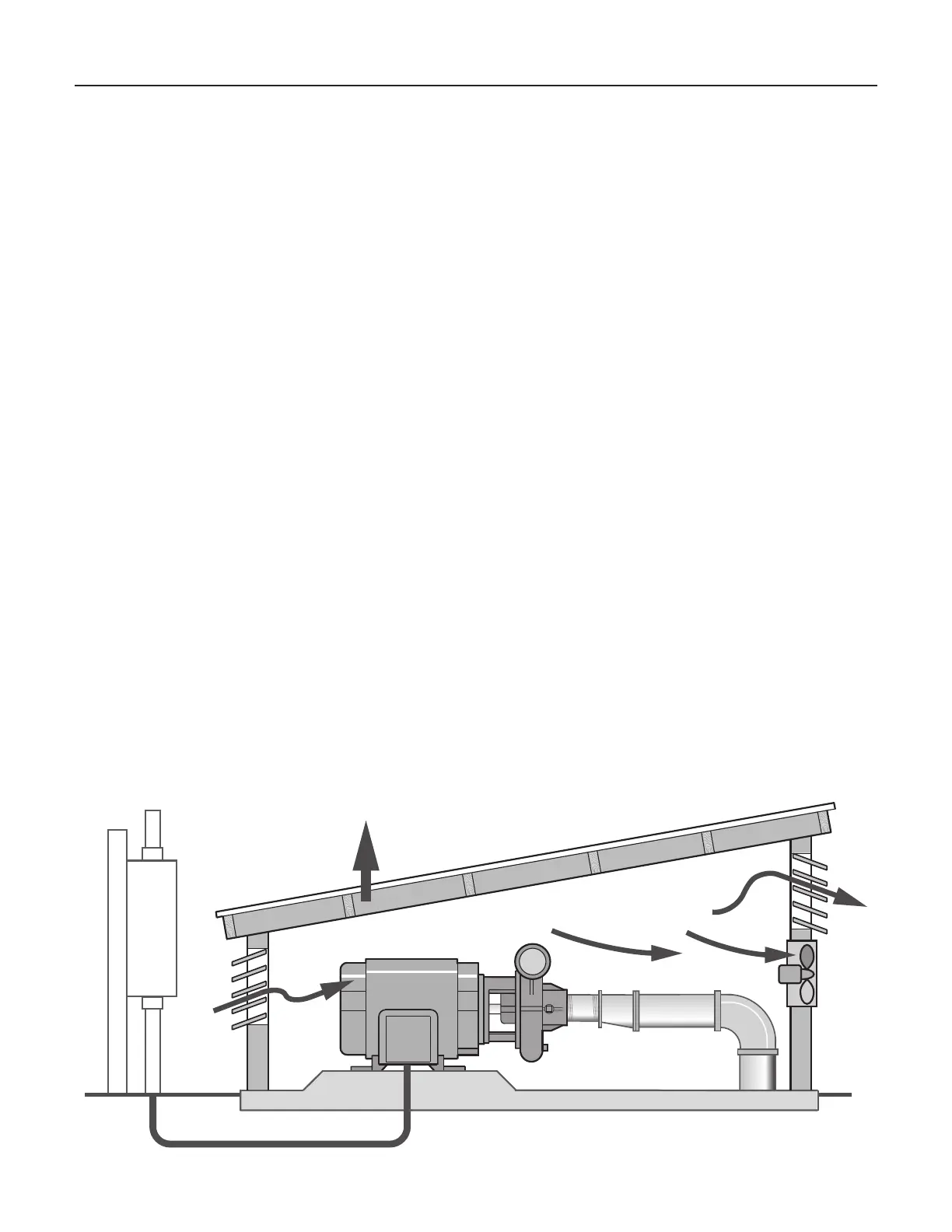

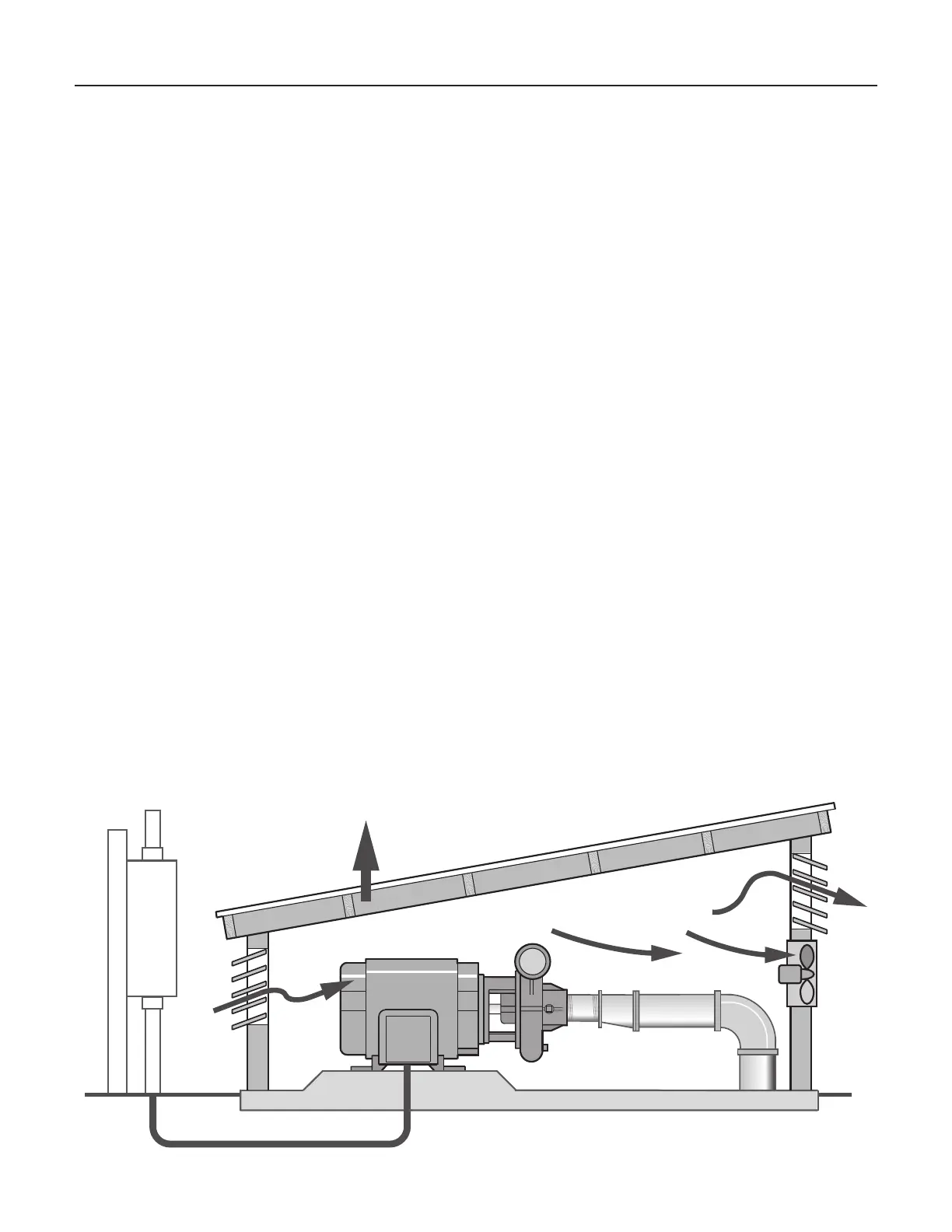

Shelter: If possible, provide shelter for unit to protect

from weather. Allow adequate space around pump

unit for service, as shown below.

• Pumpshelterwithremovableroofprotectspump

fromrain,dust,plants,andthesun.Locate

shelter to avoid flooding.

• Properventilationisamust.

• Allowforproperdrainageawayfrompump

andmotor.

• Checklocalcodesforallelectricalconnections.

• Checklocalcodesforallplumbingconnections.

Condensation: When the temperature of metal parts is

below dew point and the surrounding air is moist,

water will condense on the metal surfaces and can

cause corrosion damage. In severe situations, a

space heater can be considered to warm the unit.

Fan Recommended

Air Movement

Removable for service.

Loading...

Loading...