WHISPERFLOXF

®

VS and MAX-E-PROXF

®

VS Commercial Variable Speed Pump Installation and User’s Guide

6

External Control via Digital Inputs

When paired with either the Digital Input Wiring Kit (P/N 353129Z - Almond) or RS-485 Automation Wiring Kit (P/N

356324Z - Black), the pump can be externally controlled by digital input signals.

Note: If the pump is manually stopped using the

Start/Stop button, the pump will not run until the

Start/Stop button is pressed. If the Start/Stop

LED is illuminated, the pump is active and can be

controlled externally.

The communication cable provided with these kits

features a watertight connection that plugs into

the Pump Com Port (Figure 5 on page 5). The

opposite end of the cable has either 6 or 8 conductors

dened in Table 1.

A trigger signal is required to externally control the

pump via digital inputs. This required output signal can

to be provided in one of the following ways:

• By the pump drive. Refer to Using the Pump’s

Output Signal.

• By an external low voltage signal. Refer to Using

an External Input Signal on page 7.

Using the Pump's Output Signal

1. Route the communication cable from the Pump Com Port (Figure 5 on page 5) to the control system wiring

compartment.

2. Ensure the cable reaches all necessary terminals and cut to the necessary length.

3. Strip the cable 3/4" (19 mm).

4. Strip all 24 AWG conductors 1/2" (13 mm).

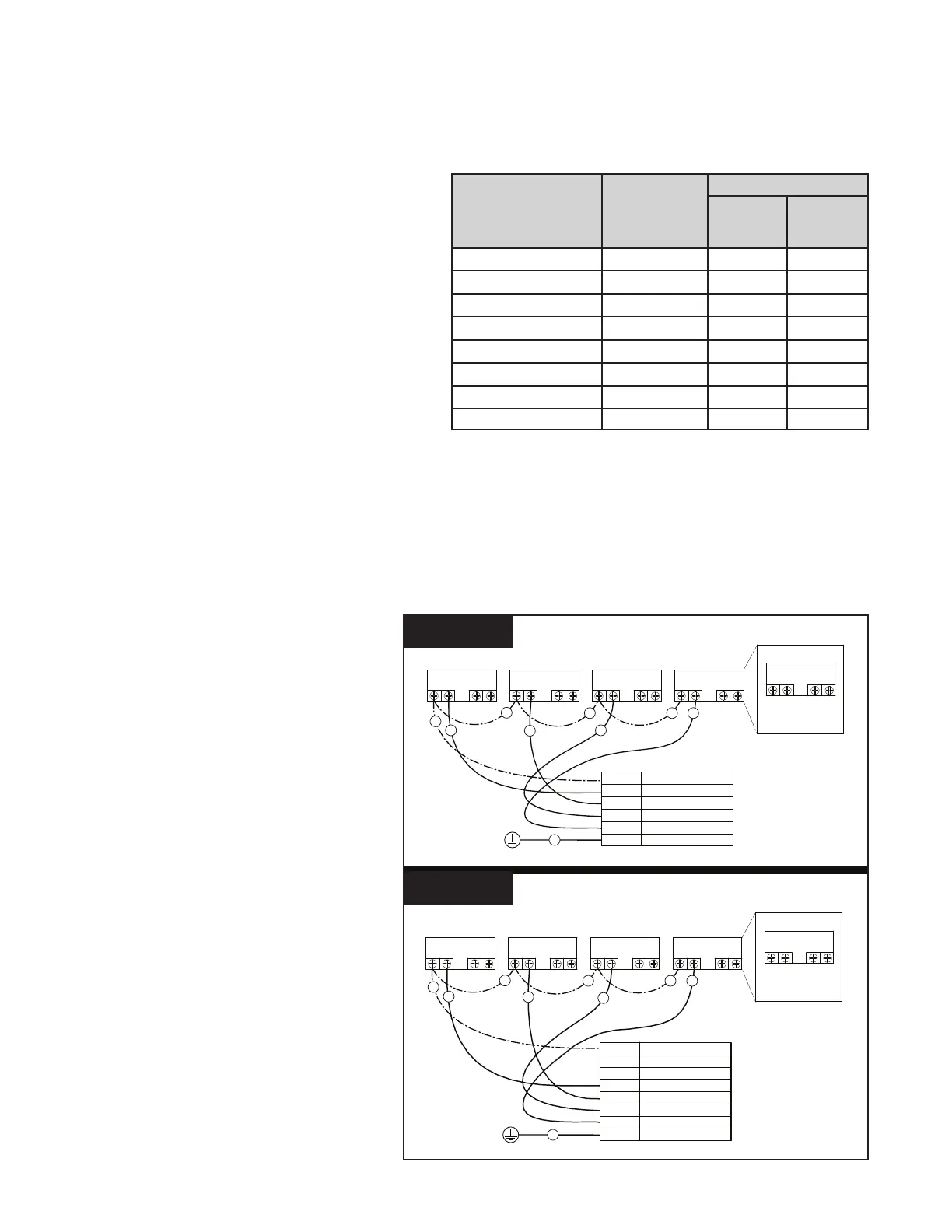

5. If using Digital Input Wiring Kit (P/N

353129Z - Almond): Wire communication

cable to control system as shown in Figure

6A.

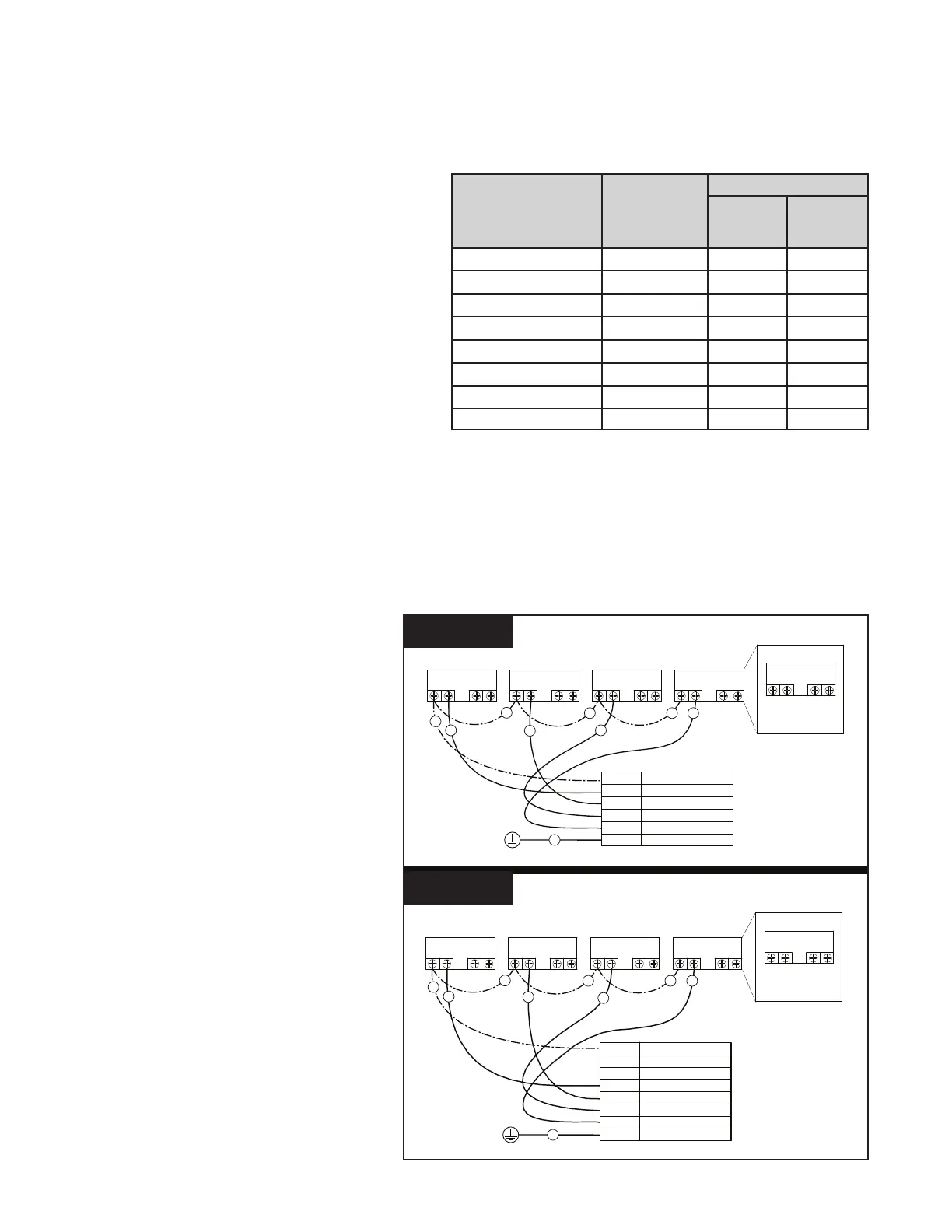

If using RS-485 Automation Wiring

Kit (P/N 356324Z - Black): Wire

communication cable to control system as

shown in Figure 6B.

Note: Unused conductors should be cut

o and terminated according to local

and national electrical codes.

6. Using the pump keypad, program the

pump's internal clock. Refer to Setting the

Clock and Pump Address on page 8.

7. Using the pump keypad, set PROGRAM 1

to 0 RPM and a duration of 24 hours. Refer

to Programming Custom Schedules on

page 8.

8. Using the pump keypad, disable priming.

Refer to Priming Adjustment on page 11.

9. When ready to start the pump, place the

pump into External Control Only mode.

Refer to External Control Only Mode on

page 7.

10. Plug the communication cable into the

Pump Com Port.

RELAY 1 RELAY 2RELAY 3RELAY 4

RELAY

LINE 1

LOAD 1

LOAD 2

LINE 2

POWER RELAY (DPST)

RED (R)

OUTPUT FOR D.I. TRIGGER

GREEN (G) SPEED 1 DIGITAL INPUT

YELLOW (Y) SPEED 2 DIGITAL INPUT

ORANGE (O)

SPEED 3 DIGITAL INPUT

BROWN (B) SPEED 4 DIGITAL INPUT

BLACK (K)GROUND

G

R

R

R

R

O

Y

B

K

RELAY 1 RELAY 2RELAY 3RELAY 4

RELAY

LINE 1

LOAD 1

LOAD 2

LINE 2

POWER RELAY (DPST)

W

R

R

R

R

O

Bl

B

K

RED (R)

OUTPUT FOR D.I. TRIGGER

WHITE (W) SPEED 1 DIGITAL INPUT

BLUE (Bl) SPEED 2 DIGITAL INPUT

ORANGE (O)

SPEED 3 DIGITAL INPUT

BROWN (B) SPEED 4 DIGITAL INPUT

BLACK (K)GROUND

GREEN (G)NOT USED

YELLOW (Y) NOT USED

Figure 6A

Figure 6B

Digital Input Wiring Kit

(P/N 353129Z - Almond)

RS-485 Automation Kit

(P/N 356324Z - Black)

Denition Signal Range

Wire Color

Wiring Kit

353129Z

Almond

Wiring Kit

356324Z

Black

+24V Output for Digital Inputs 0-20mA Red Red

RS-485 A -7V to +12V - Yellow

RS-485 B -7V to +12V - Green

PROGRAM 1 Digital Input 0, 5-30V AC/DC Green White

PROGRAM 2 Digital Input 0, 5-30V AC/DC Yellow Blue

PROGRAM 3 Digital Input 0, 5-30V AC/DC Orange Orange

QUICK CLEAN Digital Input 0, 5-30V AC/DC Brown Brown

Common Ground 0V Black Black

Table 1

Loading...

Loading...