WHISPERFLOXF

®

VS and MAX-E-PROXF

®

VS Commercial Variable Speed Pump Installation and User’s Guide

3

Only a qualied plumbing professional should install the WhisperFloXF

®

VS and Max-E-ProXF

®

VS Commercial

Variable Speed Pumps. Refer to “Important Safety Instructions” on pages i - ii for additional installation and safety

information.

INSTALLATION

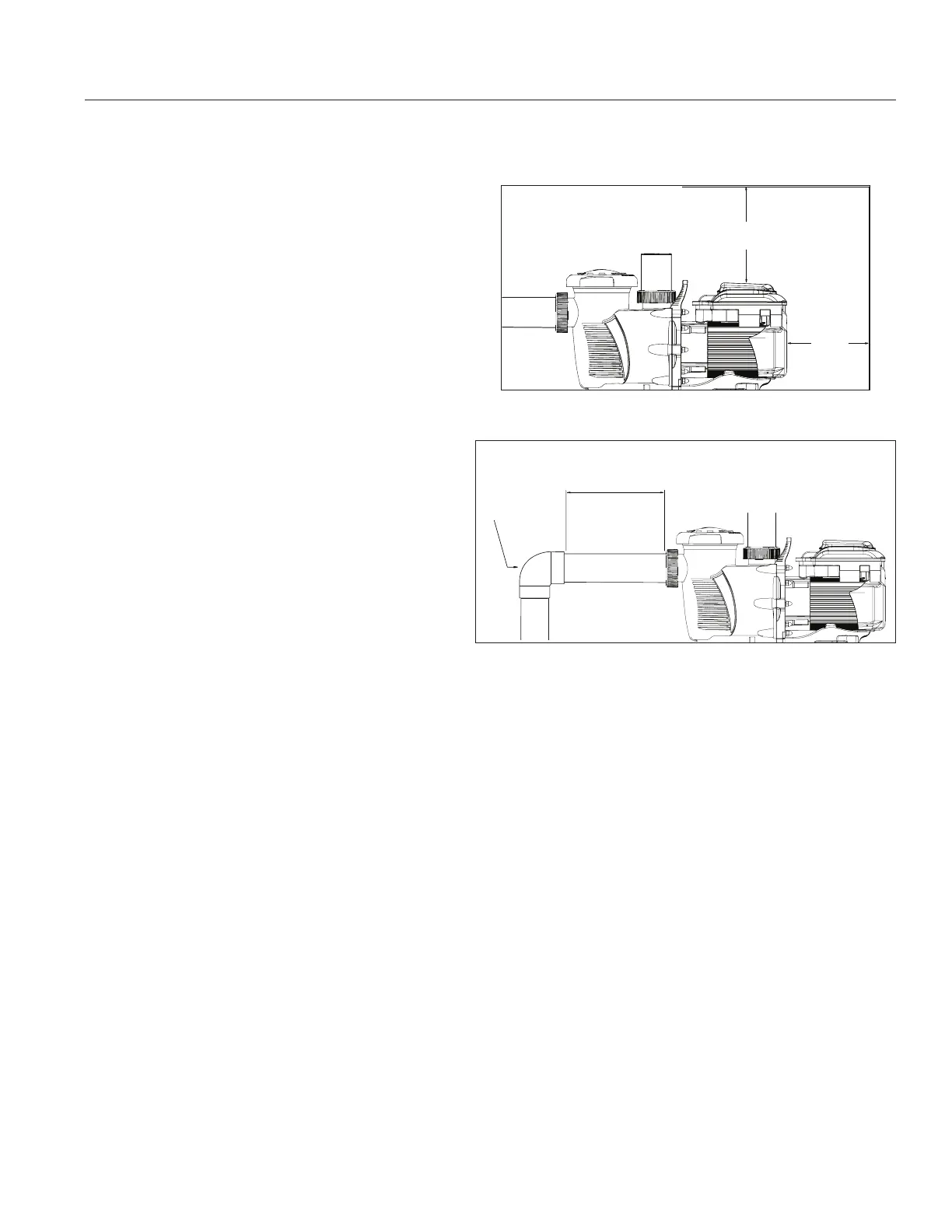

5 x SUCTION

PIPE DIAMETER

ELBOW

Figure 2

Location

Note: Do not install this pump within an outer enclosure

or beneath the skirt of a hot tub or spa unless marked

accordingly.

Note: Ensure the pump is secured to the equipment

pad.

ENSURE THE INSTALL LOCATION MEETS THE

FOLLOWING REQUIREMENTS:

1. Install the pump as close to the pool or spa as

possible. To reduce friction loss and improve

eciency, use short, direct suction and return piping.

2. Install a minimum of 5 feet (1.5 meters) from the

inside wall of the pool and spa. Canadian

installations require a minimum of 9.8 feet

(3 meters) from the inside wall of the pool.

3. Install the pump a minimum of 3 feet

(0.9 meters) from a heater outlet.

4. Do not install the pump more than 10 feet

(3.1 meters) above the water level.

5. Install the pump in a well ventilated location

protected from excess moisture (i.e. rain gutter

downspouts, sprinklers, etc.).

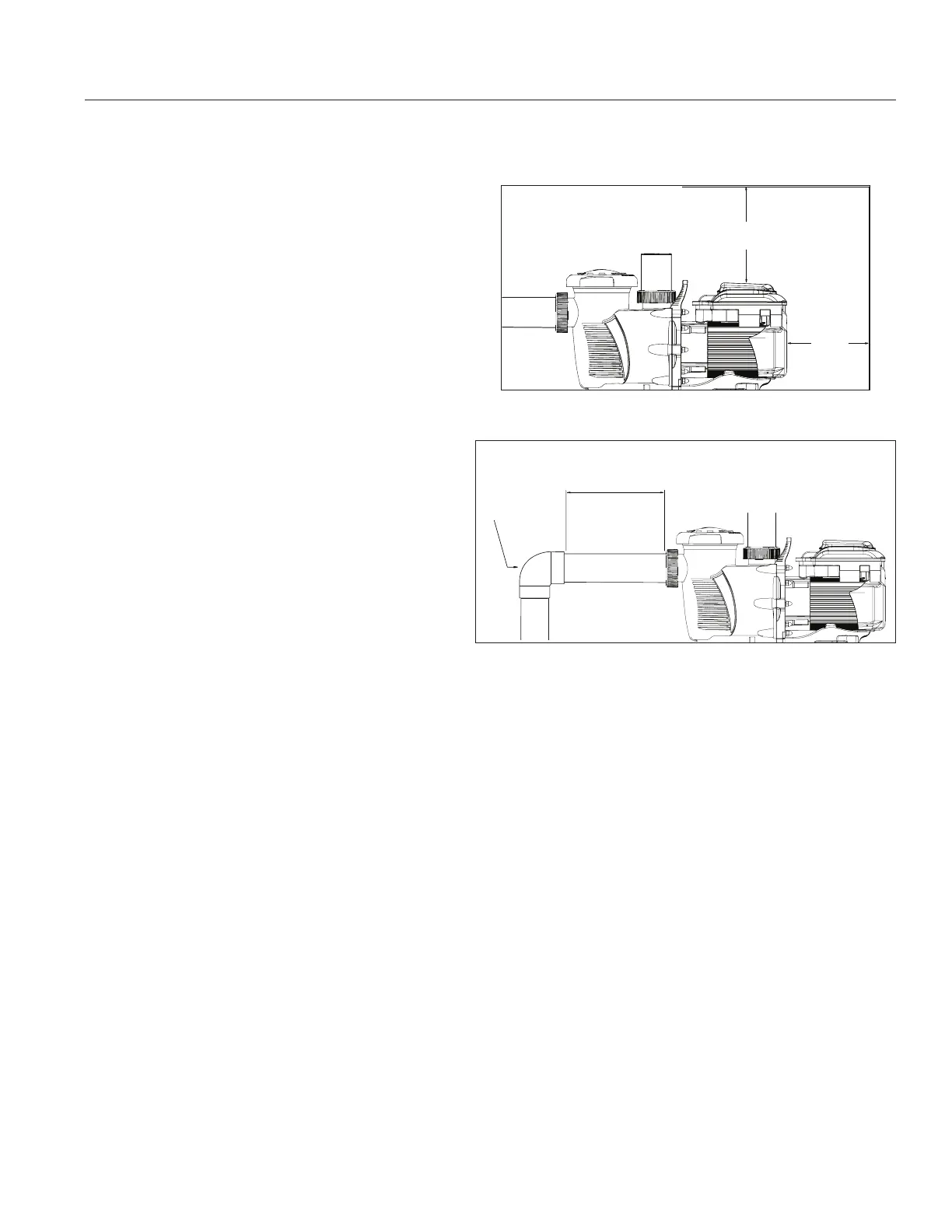

6. Install the pump with a rear clearance of at

least 3 inches (7.6 cm) so that the motor can

be removed easily for maintenance and repair. See

Figure 1.

Piping

1. For improved pool plumbing, it is recommended to

use a larger pipe size.

2. Piping on the suction side of the pump should be the

same or larger than the return line diameter.

3. Plumbing on the suction side of the pump should be

as short as possible.

4. For most installations Pentair recommends installing

a valve on both the pump suction and return lines

so that the pump can be isolated during routine

maintenance. However, we also recommend that

a valve, elbow or tee installed in the suction line

should be no closer to the front of the pump than ve

(5) times the suction line diameter. See Figure 2.

Example: A 2.5 inch pipe requires a 12.5 inch

(31.8 cm) straight run in front of the suction port.

This will help the pump prime faster and last

longer.

Note: DO NOT install 90° elbows directly into the

suction or discharge ports.

Fittings and Valves

1. Do not install 90° elbows directly into suction port.

2. Flooded suction systems should have gate

valves installed on suction and discharge pipes

for maintenance, however, the suction gate valve

should be no closer than ve (5) times the suction

pipe diameter as described in this section.

3. Use a check valve in the discharge line when

using this pump for any application where there is

signicant height to the plumbing after the pump.

4. Be sure to install check valves when plumbing in

parallel with another pump. This helps prevent

reverse rotation of the impeller and motor.

Electrical Requirements

• Install all equipment in accordance with the National

Electrical code and all applicable local codes and

ordinances.

• A means for disconnection must be incorporated in

the xed wiring in accordance with the wiring rules.

Figure 1

6 IN. (15.2 CM)

MINIMUM

3 IN.

(7.6 CM)

MINIMUM

Loading...

Loading...