6500 Series Purge and Pressurization System

I/O Manual

23

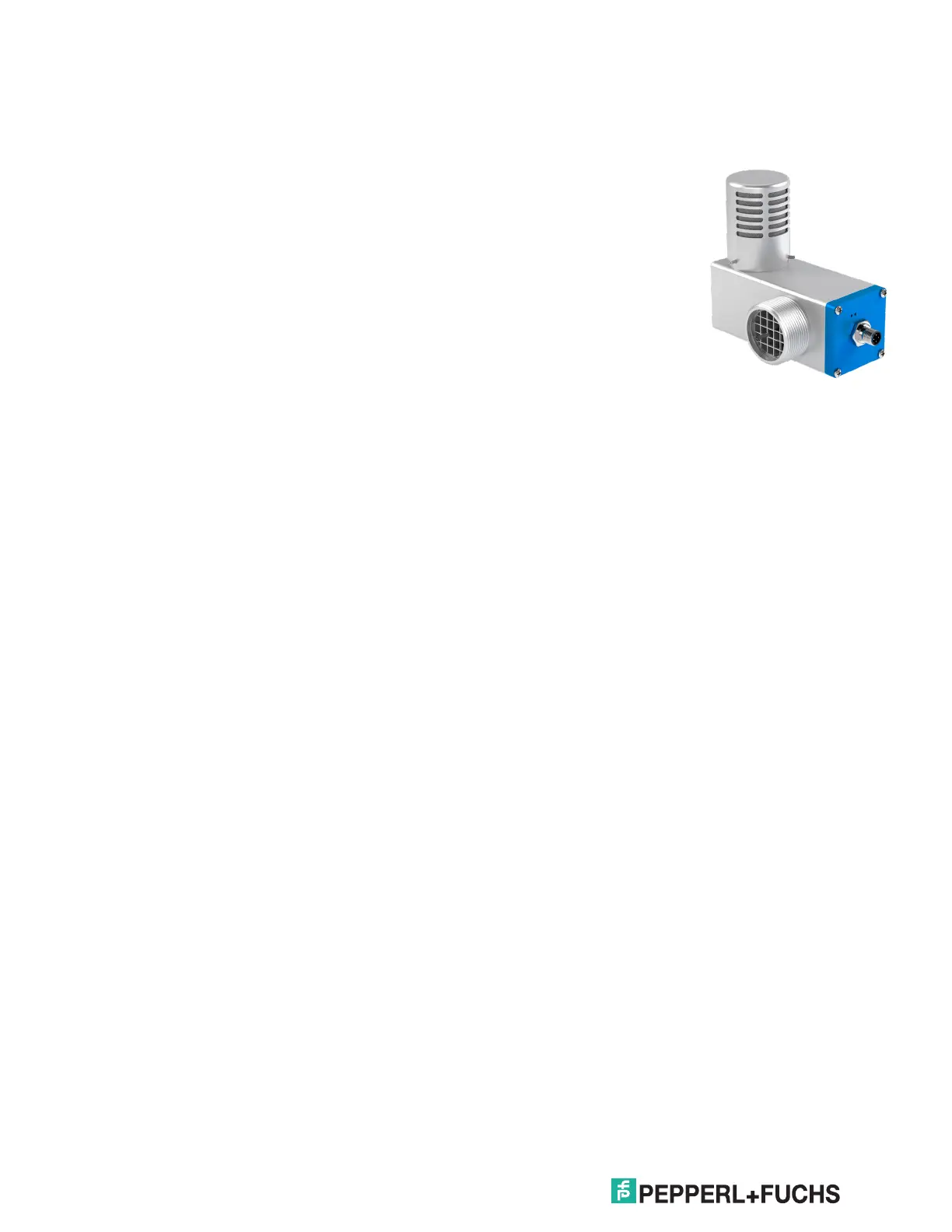

3 EPV-6500 pressure relief vent

3.1 Introduction

The EPV-6500 vent is required for the 6500 control unit and will

provide a functional, certifiable purge and pressurization system

for enclosures. As required by all pressurized enclosure systems,

the EPV-6500 vent functions as a pressure relief device and allows

the purge gas to exit the enclosure, yet provides a seal when the

enclosure is pressurized below its pressure relief breaking pressure.

The vent also has a spark arrestor as required for hazardous area

operation.

The EPV-6500 vent has a pressure sensor for measurement of

enclosure pressure and a flow sensor for measuring purging flow

and/or dilution flow through the exhaust of the vent.

The two types of vents available are for standard applications (no containment system within the

pressurized enclosure) and dilution applications (containment systems within the enclosure – ex: analyzer

applications) and within these two groups are selections for different flows and purging pressures.

All vents can be mounted externally or internally to the pressurized enclosure; they are not position

oriented. For internal mount only, the vent cap is exposed on the outside of the pressurized enclosure and

the reference pressure connection to the vent has to be added for correct pressure and flow measurement.

Connection fitting and tubing is included with the stainless steel cap version.

Standard Vents:

EPV-6500-__-01: Normally used with large enclosures for shorter purge times. This vent allows

the maximum flow through the enclosure for the minimum enclosure pressures. For large enclosures,

this will keep the forces on the enclosure low while having the largest purge flow off all the EPV

selections. The vent also has a higher leakage rate after purging (pressurization), but normally on

large enclosures the leakage rate is much greater than the vent leakage and does not become a

EPV-6500-__-03: Normally used with medium or large enclosures where the leakage rate is critical

and a short purging time is required. Because the seal is better than the ‘-01’ model, the back

pressure during purging will be higher; however, the leakage rate for pressurization is lower.

EPV-6500-__-05: Gives the best seal for pressurization but highest back pressure for purging.

These vents are extremely useful for pressure supply or bottled pressure sources.

Dilution Vent:

EPV-6500-__-07: The vent has a 8 mm diameter opening and requires a continuous flow to maintain

pressure/flow. The flow is measured across this 8 mm orifice plate for greater accuracy. When used

around 85 l/min (3 scfm).

EPV-6500-__-08: The vent has a 16 mm diameter opening and requires a continuous flow to

maintain pressure/flow. The flow is measured across this 16 mm orifice plate for greater accuracy.

(2.5 scfm) to around 226 l/min (8 scfm).

Loading...

Loading...