54 SEBU8121

Maintenance Section

Alternator - Inspect

i02176674

Alternator - Inspect

Perkins recomm

ends a scheduled inspection of

the alternator. Inspect the alternator for loose

connections and correct battery charging. Inspect the

ammeter (if eq

uipped) during engine operation in

order to ensure correct battery performance and/or

correct performance of the electrical system. Make

repairs, as r

equired.

Check the alternator and the battery charger for

correct oper

ation. If the batteries are correctly

charged, the ammeter reading should be very near

zero. All batteries should be kept charged. The

batteries s

hould be kept warm because temperature

affects the cranking power. If the battery is too cold,

the battery will not crank the engine. When the

engine is no

t run for long periods of time or if the

engine is run for short periods, the batteries may not

fully charge. A battery with a low charge will freeze

more easil

y than a battery with a full charge.

i01929797

Alternator and Fan Be lts -

Inspect/Adjust/Replace

Inspection

To maximize the engine performance, inspect the

belts for wear and for cracking. Replace belts that are

worn or damaged.

For applications that require multiple drive belts,

replace the belts in matched sets. Replacing only

one belt of a matched set will cause the new belt to

carry more load because the older belt is stretched.

The additional load on the new belt could cause the

new belt to break.

If the belts are too loose, vibration causes

unnecessary wear on the belts and pulleys. Loose

belts may slip enough to cause overheating.

To accurately check the belt tension, a suitable gauge

should be used.

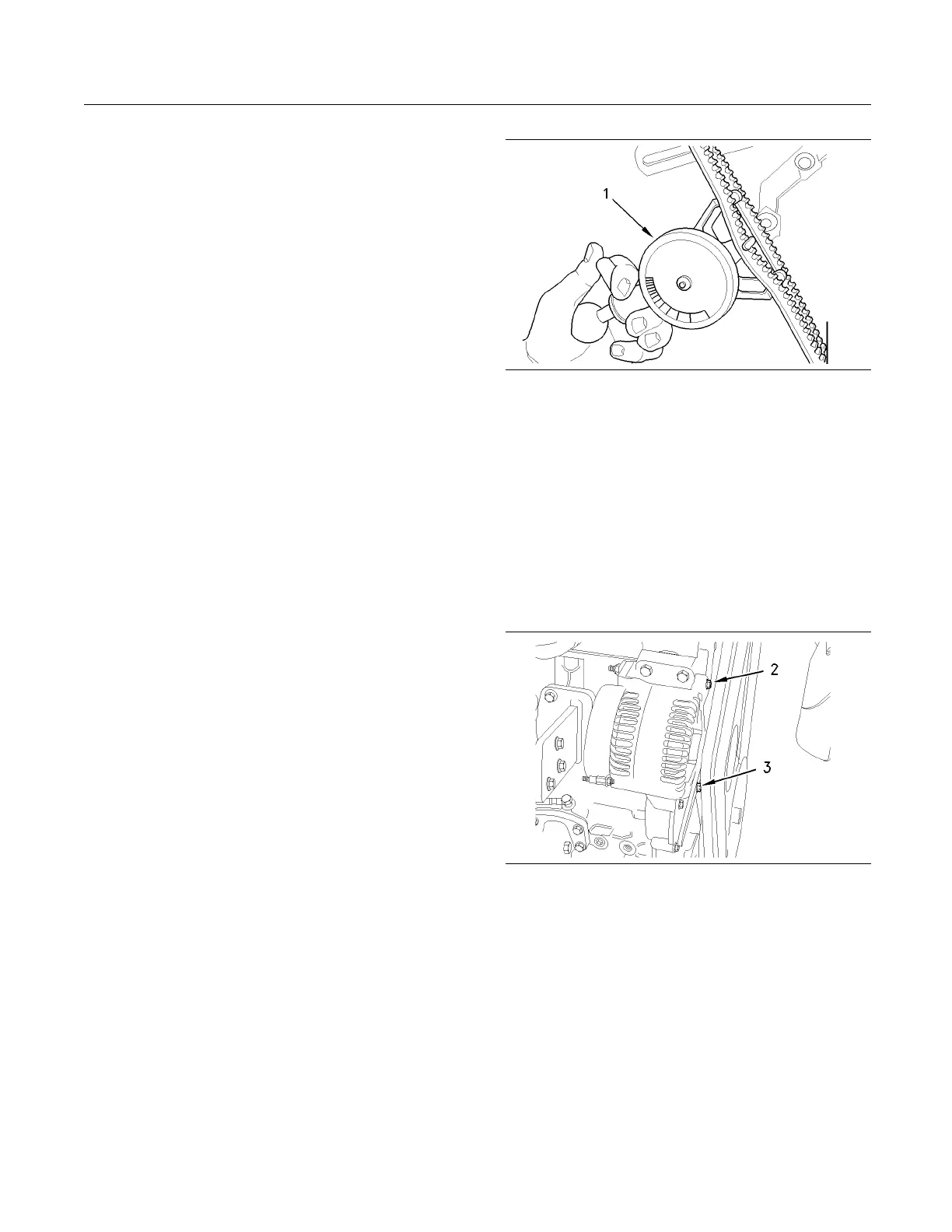

g01003936

Illustration 20

Typical example

(1) Burroughs Gauge

Fit the gauge (1) at the center of the longest free

length and check the tension. The correct tension

is 535 N (120 lb). If the tension of the belt is below

250 N (56 lb) adjust the belt to 535 N (120 lb).

If twin belts are installed, check and adjust the

tensiononbothbelts.

Adjustment

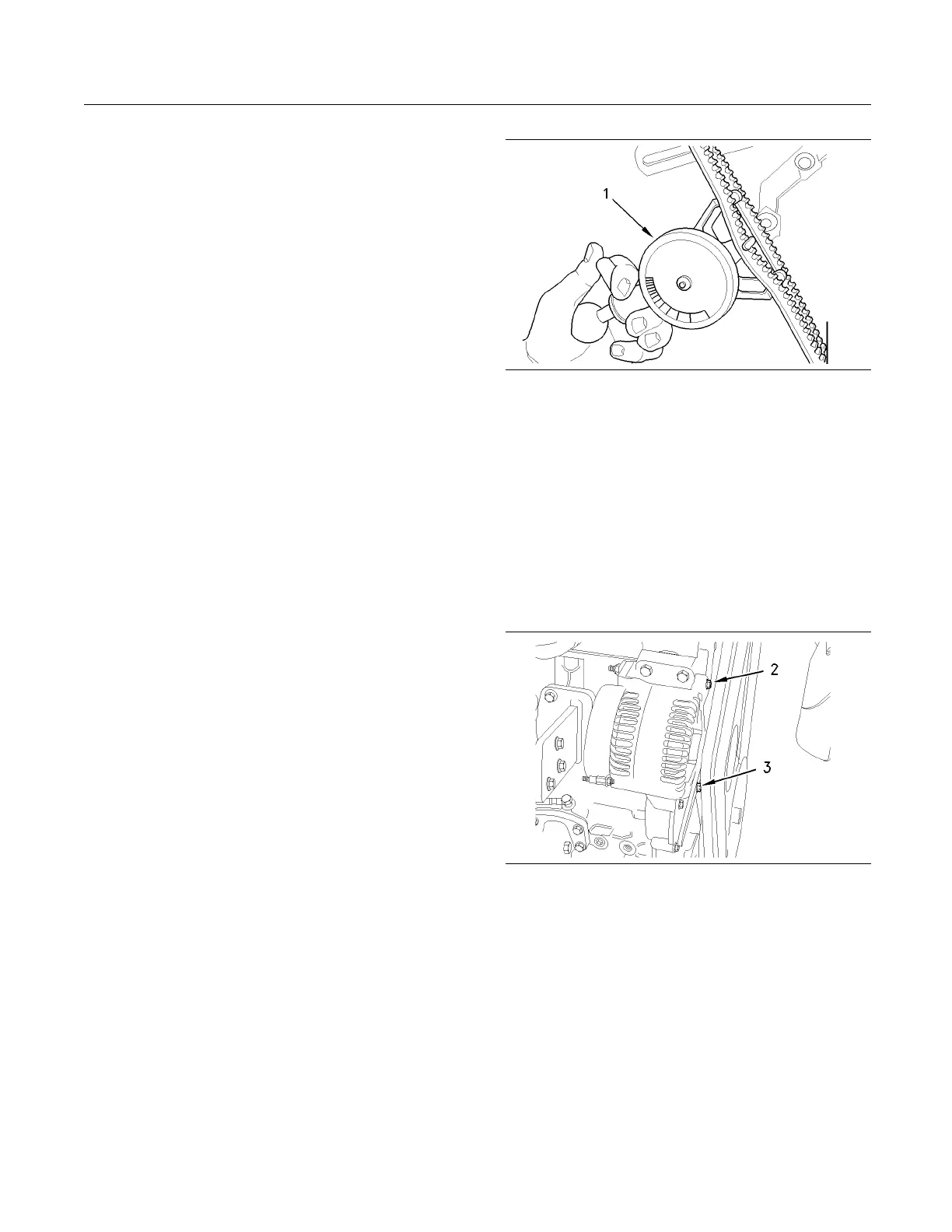

g01003939

Illustration 21

1. Loosen Th

e alternator pivot bolt (2) and the bolt

(3).

2. Move the a

lternator in order to increase or

decrease the belt tension. Tighten the alternator

pivot bolt and the link bolt to 22 N·m (16 lb ft).(1).

Replacement

Refer to the Disassembly and Assembly Manual for

the installation procedure and the removal procedure

for the b

elt.

Loading...

Loading...