SEBU8121 69

Maintenance Section

Engine Protective Devices - Check

Note: Some engi

nes may have a horizontally

mounted oil filter. This oil filter has a drain plug that is

located in the oil filter head.

Fill th e Engine Crankcase

1. Remove the oil filler cap. Refer to the Operation

and Maintenance Manual for more information on

lubricant sp

ecifications. Fill the crankcase with the

proper amount of oil. Refer to the Operation and

Maintenance Manual for more information on refill

capacities.

NOTICE

If equipped with an auxiliary oil filter system or a re-

mote oil filter system, follow the OEM or filter manu-

facturer’s recommendations. Under filling or overfilling

the crankcase with oil can cause engine damage.

NOTICE

To prevent crankshaft bearing damage, crank the en-

gine with th

efuelOFF.Thiswillfilltheoilfiltersbefore

starting the engine. Do not crank the engine for more

than 30 seconds.

2. Start the en

gine and run the engine at “LOW

IDLE” for two minutes. Perform this procedure in

order to ensure that the lubrication system has

oil and that

the oil filters are filled. Inspect the oil

filter for oil leaks.

3. Stop the eng

ine and allow the oil to drain back to

thesumpforaminimumoftenminutes.

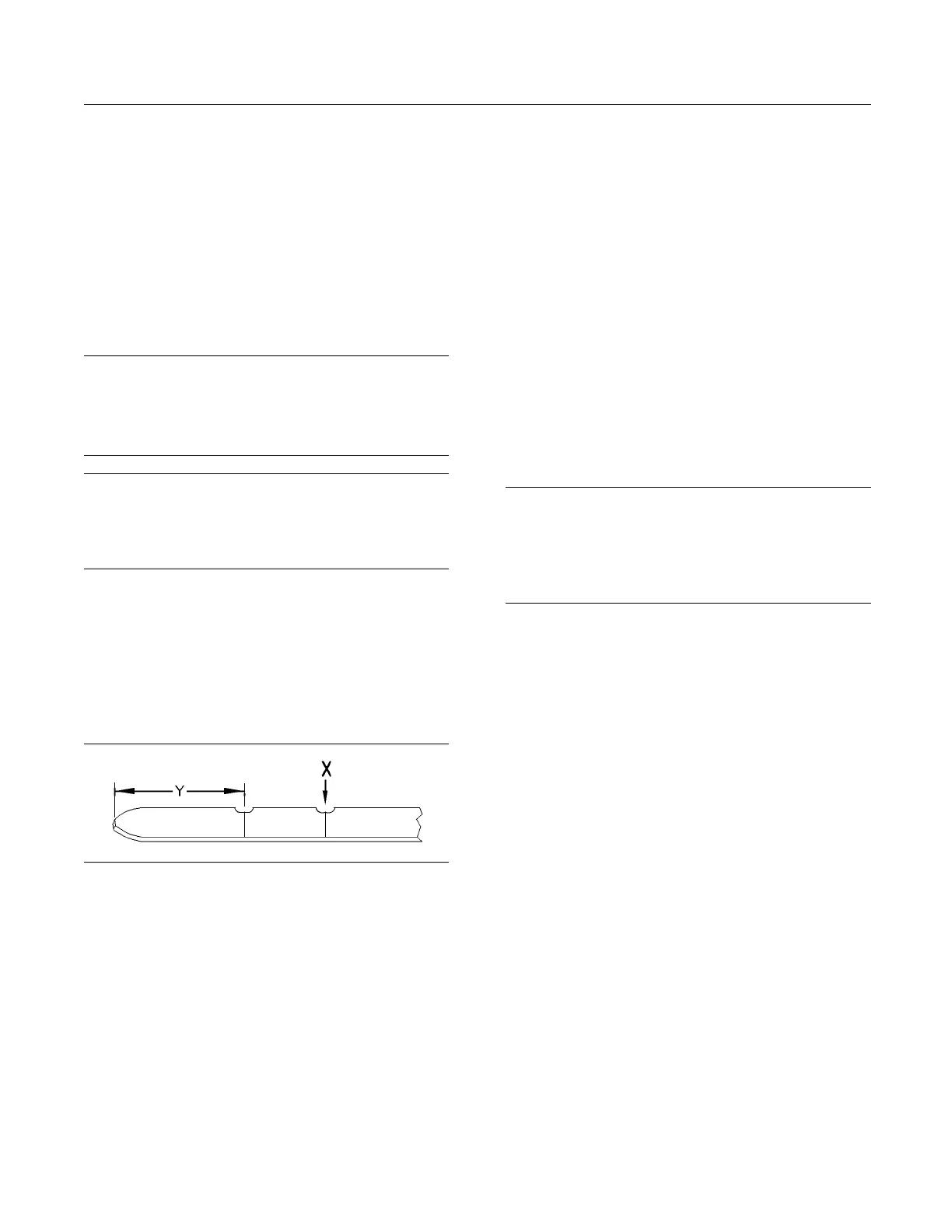

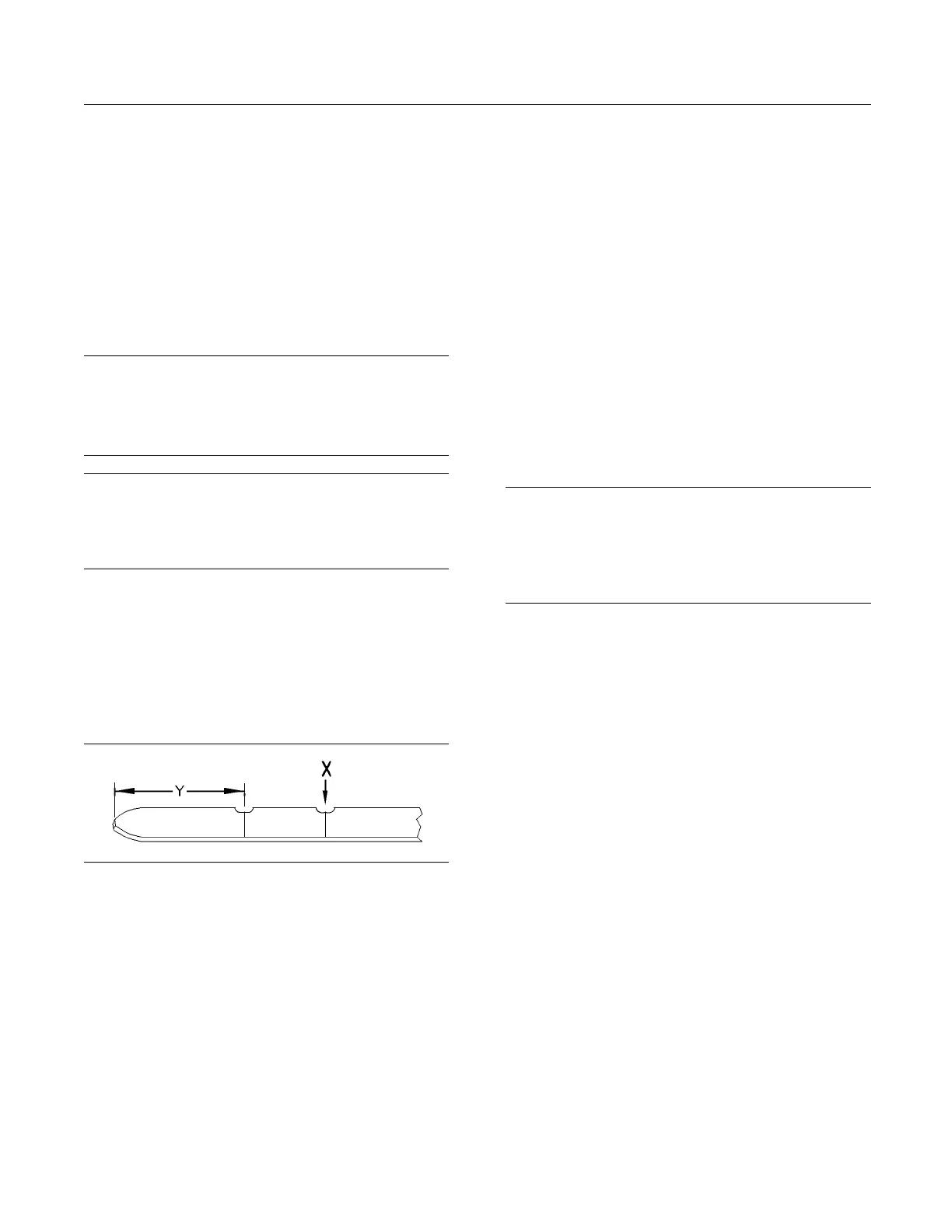

g00998024

Illustration 37

(Y) “ADD” mark. (X) “FUL L ” mark.

4. Remove the oil level gauge in order to check the

oil level. Maintain the oil level between the “ADD”

and “FULL” marks on the engine oil dipstick.

i01907676

Engine Protective Devices -

Check

Alarms and shutoffs (if equipped) must function

properly. Alarms provide timely warning to the

operator. Shu

toffs help to prevent damage to the

engine. It is impossible to determine if the engine

protective devices are in good working order during

normal opera

tion. Malfunctions must be simulated in

order to test the engine protective devices.

Acalibratio

n check of the engine protective devices

will ensure that the alarms and shutoffs activate at the

setpoints. Ensure that the engine protective devices

are functio

ning properly. Refer to OEM information

for more information.

NOTICE

During testing, abnormal operating conditions must be

simulated.

The tests must be performed correctly in order to pre-

vent possib

le damage to the engine.

To prevent damage to the engine, your authorized

Perkins dea

ler or your Perkins distributor should

perform the tests.

Visual Inspection

Visually c

heck the condition of all gauges, sensors

and wiring. Look for wiring and components that

are loose, broken, or damaged. Damaged wiring

or compone

nts should be repaired or replaced

immediately.

i02171102

Engine Valve Lash -

Inspect/Adjust

This maintenance is recommended by Perkins as

part of a lubrication and preventive maintenance

schedule in order to help provide maximum engine

life.

Loading...

Loading...