62 SEBU8121

Maintenance Section

Driven Equipment - Check

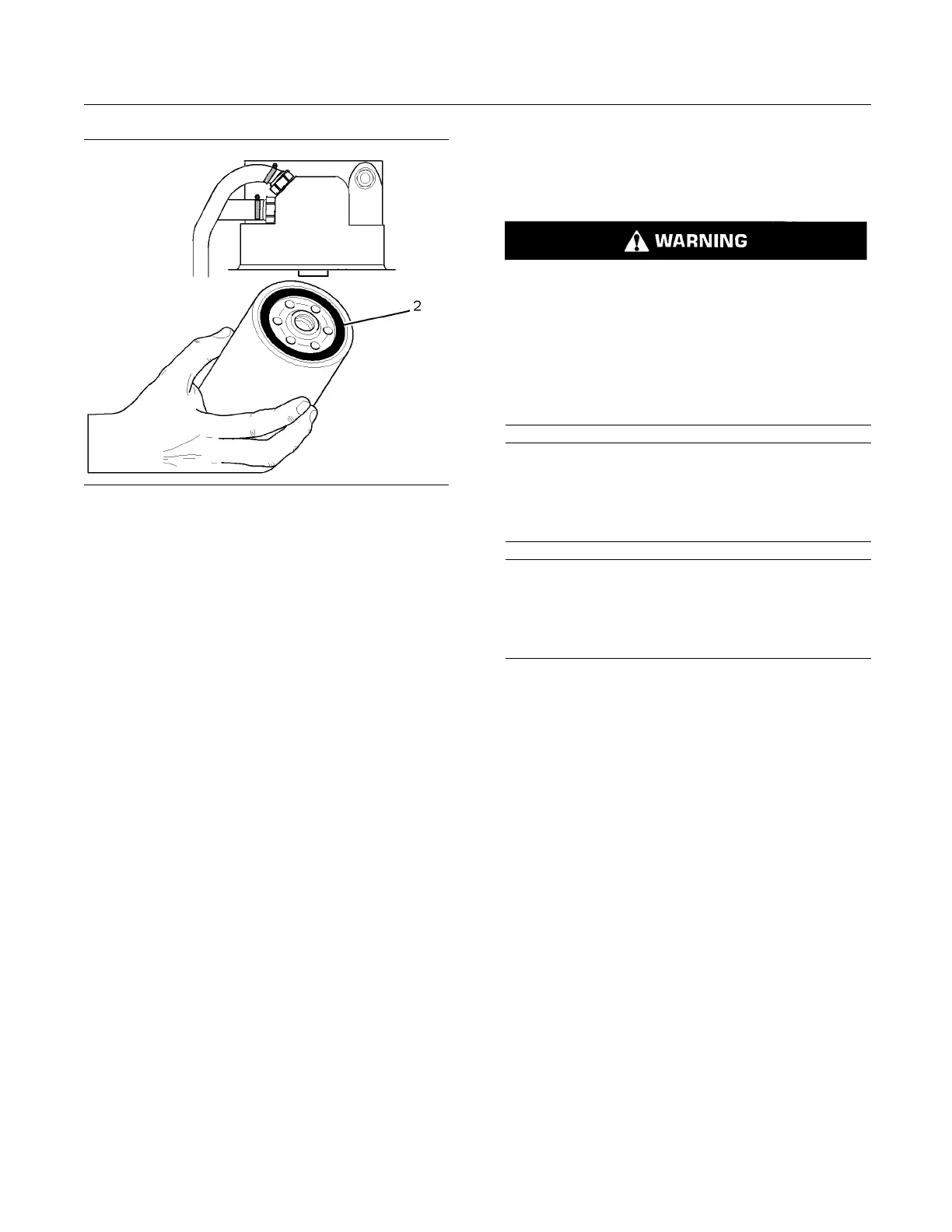

g01145188

Illustration 27

Typical example

2. Lubricate the O-ring seal (2) and install the

canister. Tighten the canister to 12 N·m (8 lb ft).

i00174798

Driven Equ ipm ent - Chec k

Refer to the OEM specifications for more information

on the following maintenance recommendations for

the driven equipment:

•

Inspection

•

Adjustment

•

Lubrication

•

Other maintenance recommendations

Perform any maintenance for the driven equipment

which is recommended by the OEM.

i01909392

Engine - Clean

Personal injury or death can result from high volt-

age.

Moisture can create paths of electrical conductiv-

ity.

Make sure that the electrical system is OFF. Lock

out the starting controls and tag the controls “DO

NOT OPERATE”

.

NOTICE

Accumulatedgreaseandoilonanengineisafirehaz-

ard. Keep the engine clean. Remove debris and fluid

spills whenever a significant quantity accumulates on

the engine.

NOTICE

Failure to protect some engine components from

washing may make your engine warranty invalid.

Allow the eng

inetocoolforonehourbeforewashing

the engine.

Periodic cle

aning of the engine is recommended.

Steam cleaning the engine will remove accumulated

oil and grease. A clean engine provides the following

benefits:

•

Easy detection of fluid leaks

•

Maximum heat transfer characteristics

•

Ease of main

tenance

Note: Caution must be used in order to prevent

electrical

components from being damaged by

excessive water when the engine is cleaned.

Pressure washers and steam cleaners should not be

directed at

any electrical connectors or the junction of

cables into the rear of the connectors. Avoid electrical

components such as the alternator, the starter, and

the ECM. Pr

otect the fuel injection pump from fluids

in order to wash the engine.

Loading...

Loading...