7. Install hose (4) and tighten clip (3) securely . Install

hose (2) and tighten clip (1) securely.

i05970985

Grounding Stud - Inspect/

Clean/Tighten

The connection of battery cables to a battery and

the disconnection of battery cables from a battery

may cause an explosion which may result in in-

jury or death. The connection and the disconnec-

tion of other electrical equipment may also cause

an explosion which may result in injury or death.

The procedures for the connection and the dis-

connection of battery cables and other electrical

equipment should only be performed in a nonex-

plosive atmosphere.

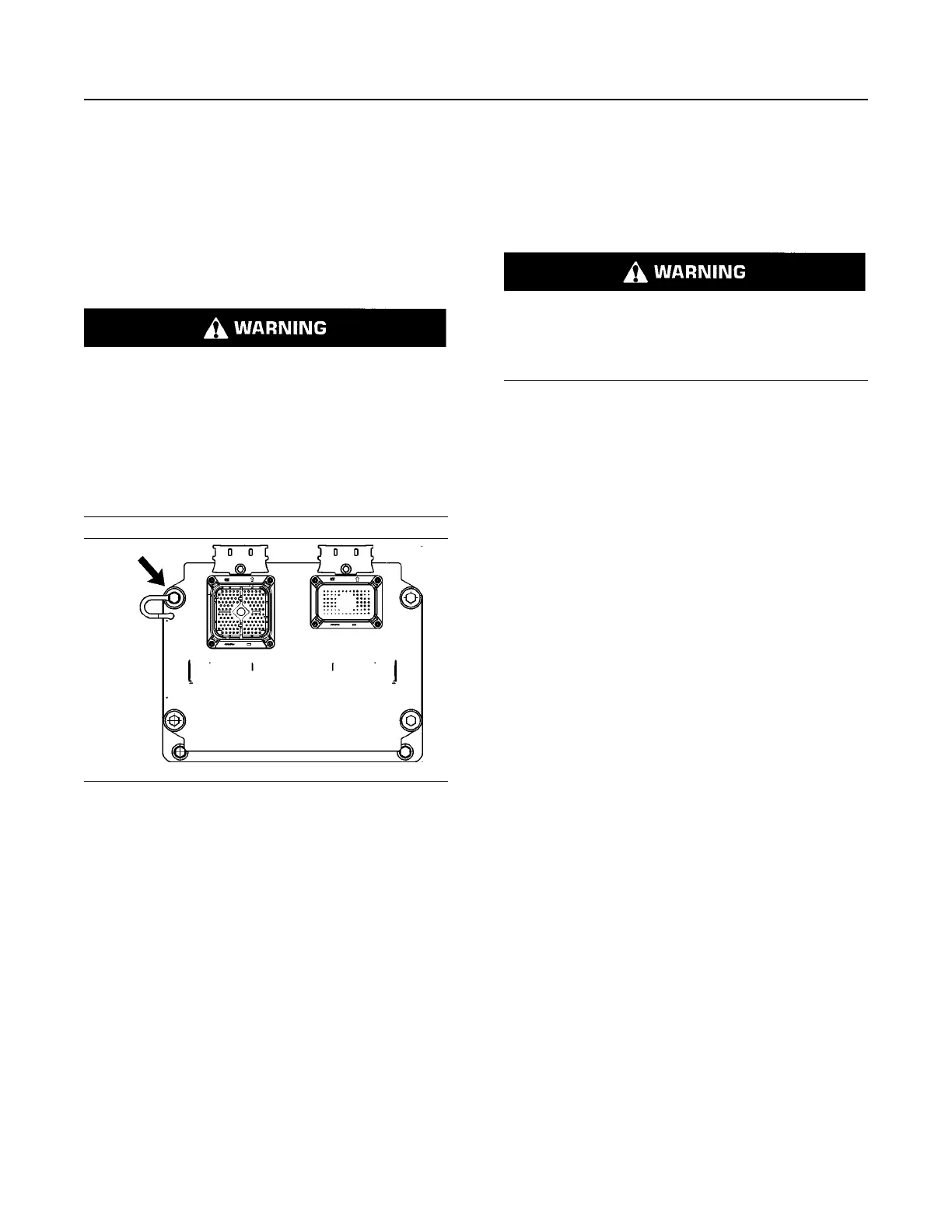

Illustration 94 g01376112

The electronics grounding stud is located on the

upper left corner of the engine control module.

Inspect the OEM harness for good connections.

Inspect the condition of the OEM harness.

The electronics grounding stud must have a wire

ground to the battery. Tighten the electronics

grounding stud at every oil change. Ground wires

and straps should be combined at engine grounds.

All grounds should be tight and free of corrosion.

• Clean the electronics grounding stud and the

terminals for the ground strap with a clean cloth.

• If the connections are corroded, clean the

connections with a solution of baking soda and

water.

• Keep the electronics grounding stud and the strap

clean and coated with MPGM grease or petroleum

jelly.

i06103230

Hoses and Clamps - Inspect/

Replace

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fuel

spray may cause a fire hazard. Failure to follow

these inspection, maintenance and service in-

structions may cause personal injury or death.

If you inspect the engine in operation, always use the

proper inspection procedure in order to avoid a fluid

penetration hazard. Refer to Operation and

Maintenance Manual, “General hazard Information”.

Inspect all hoses for leaks that are caused by the

following conditions:

• Cracking

• Softness

• Loose clamps

Replace hoses that are cracked or soft. Tighten any

loose clamps.

Check for the following conditions:

• End fittings that are damaged or leaking

• Outer covering that is chafed or cut

• Exposed wire that is used for reinforcement

• Outer covering that is ballooning locally

• Flexible part of the hose that is kinked or crushed

• Armoring that is embedded in the outer covering

A constant torque hose clamp can be used in place

of any standard hose clamp. Ensure that the constant

torque hose clamp is the same size as the standard

clamp.

Due to extreme temperature changes, the hose will

harden. Hardening of the hoses will cause hose

clamps to loosen. This hardening can result in leaks.

A constant torque hose clamp will help to prevent

loose hose clamps.

Each installation application can be different. The

differences depend on the following factors:

• Type of hose

• Type of fitting material

• Anticipated expansion and contraction of the hose

114

SEBU9071-06

Maintenance Section

Grounding Stud - Inspect/Clean/Tighten

Loading...

Loading...