(Table 14, contd)

Alternator

belt

645 ± 44 N

(145 ± 10 lb)

512 ± 44 N

(115 ± 10. lb)

311 ± 44 N

(70 ± 10 lb)

Fan Belt

801 ± 44 N

(180 ± 10 lb)

645 ± 44 N

(145 ± 10 lb)

378 ± 44 N

(85 ± 10 lb)

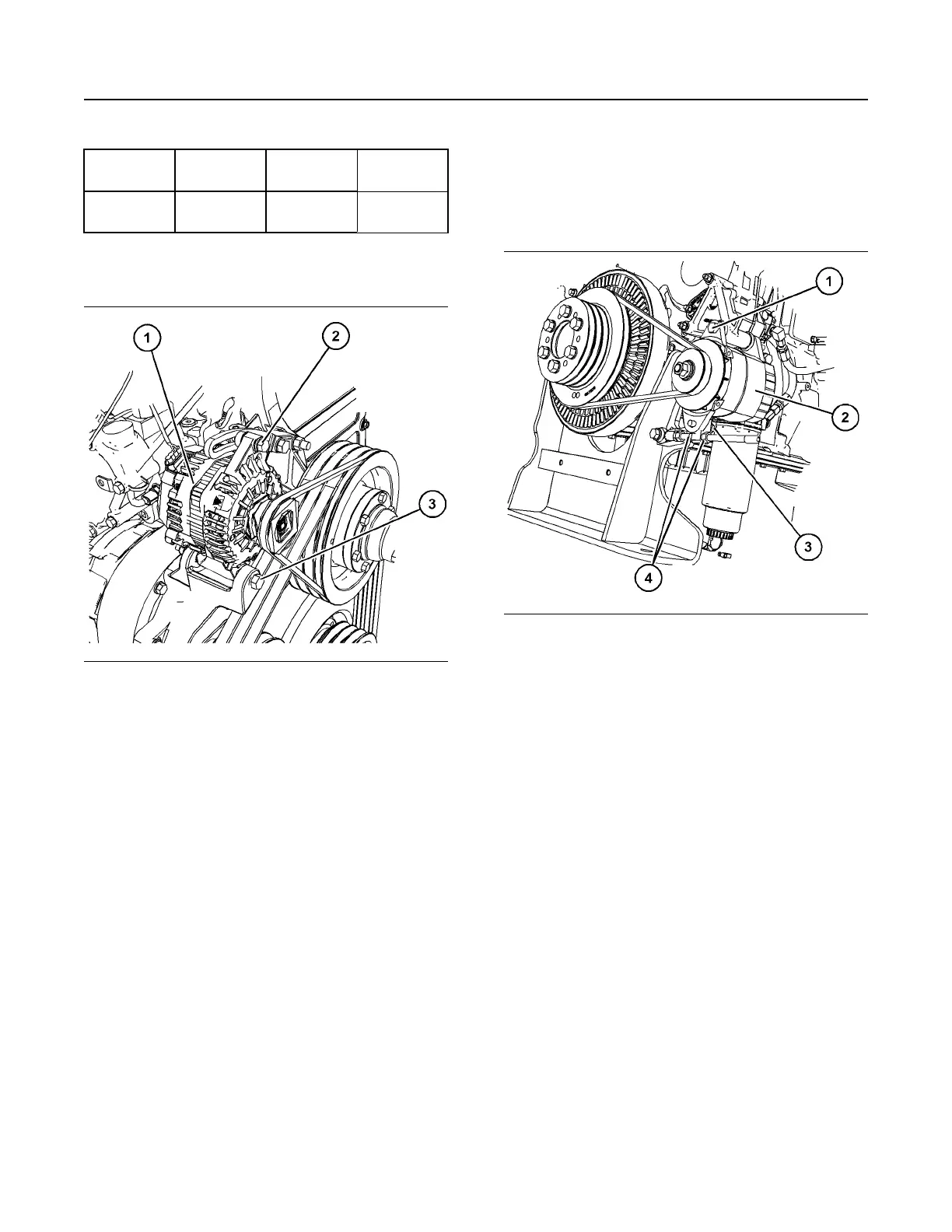

Alternator Belt Adjustment 2806C

Illustration 35 g06108813

Typical example

1. Remove guards, refer to the Original Equipment

Manufacture (OEM) for the correct procedure.

2. Loosen nut and bolt (2) and loosen nut and bolt

(3).

3. Adjust alternator (1) to obtain the correct tension

on the belt. Use a suitable belt tension tool to set

the belt tension.

4. Tighten nut and bolt (2) and tighten nut and bolt

(3).

5. Tighten nut and bolt (2) to a torque of 47 N·m

(34 lb ft). Tighten nut and bolt (3) to a torque of

70 N·m (51 lb ft).

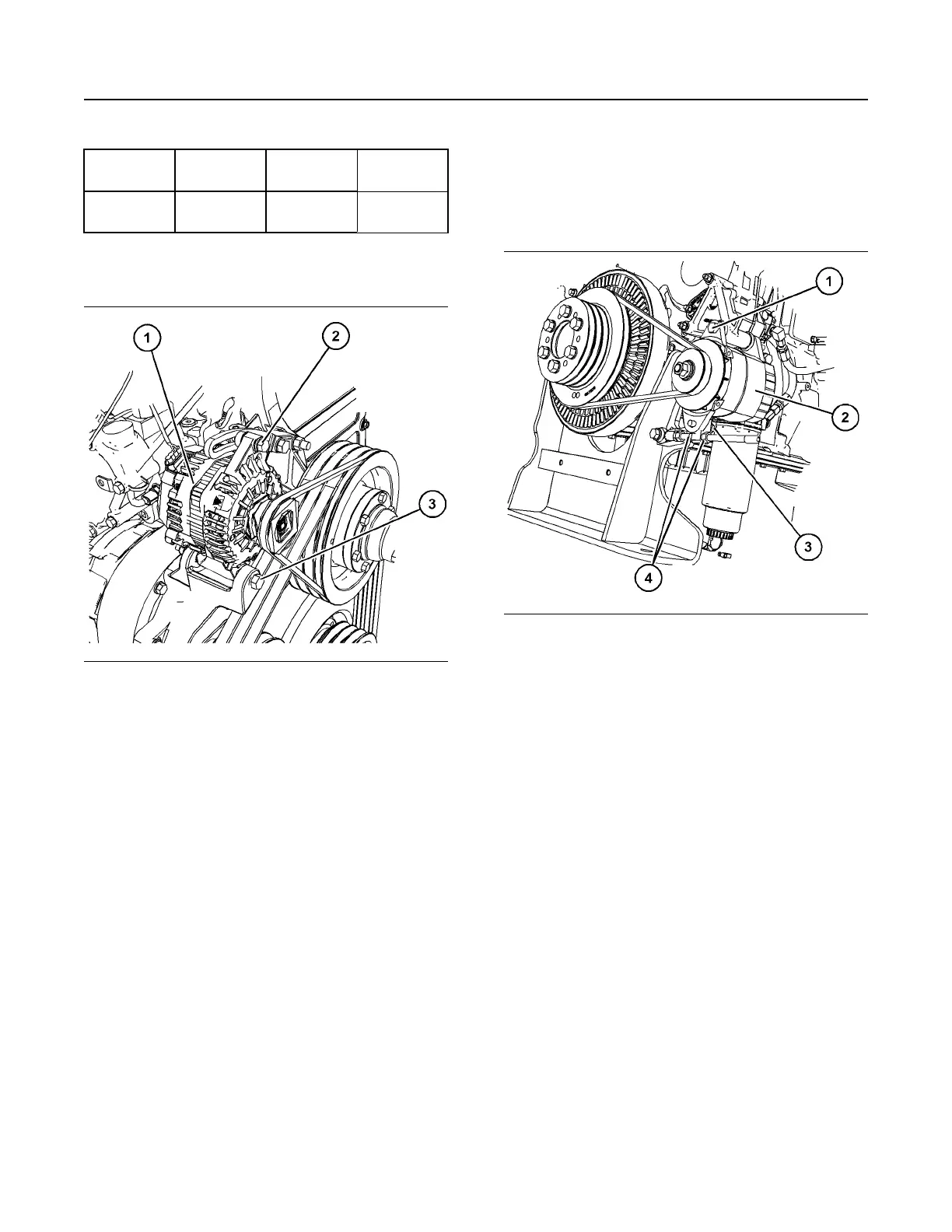

Alternator Belt Adjustment 2806D

Illustration 36 g06109400

2806D engine view

1. Remove the belt guard, refer to OEM for the

correct procedure.

2. Loosen nut and bolt (1) and loosen bolt (3).

3. Loosen one of the nuts (4). Adjusting nuts (4) will

move the alternator (2).

4. Adjust nuts (4) for the correct tension on the belt.

Use a suitable belt tension tool to set the belt

tension.

5. With the correct tension set, tighten nut and bolt

(1) and tighten bolt (3).

6. Tighten nut and bolt (1) to a torque of 105 N·m

(77 lb ft).

7. Tighten bolt (3) to a torque of 105 N·m (77 lb ft).

8. Tighten nuts (4) to a torque of 105 N·m (77 lb ft).

9. Reinstall the belt guard, refer to OEM for the

correct procedure.

SEBU9074-01

67

Maintenance Section

Belts - Inspect/Adjust/Replace

Loading...

Loading...