Note: Ensure that the Allen screws are tightened

equally. Failure to ensure that the Allen screws are

tightened equally will result in damage to the fuel

injection pump.

9. Tighten the Allen head screws to a torque of 9 N·m

(80 lb in).

10. Connect harness assembly (1) to flow control

valve (3).

11. Replace the filters for primary fuel system. Refer

to Operation and Maintenance Manual, “Fuel

System Primary (Water Separator) Element -

Replace” for the correct procedure.

12. Replace the filters for secondary fuel system.

Refer to Operation and Maintenance Manual, “Fuel

System Secondary Filter - Replace” for the correct

procedure.

13. Turn the fuel supply to the ON position.

14. Turn the battery disconnect switch to the ON

position.

15. Remove the air from the fuel system. Refer to

Operation and Maintenance Manual, “Fuel System

- Prime” for more information.

End By:

a. After replacement of the flow control valve, the fuel

injection pump requires a high-pressure fuel pump

calibration procedure to be performed. Refer to

Troubleshooting, “Fuel Rail Pressure Problem” for

the correct procedure.

i06213344

Fuel Filter Base - Remove and

Install

Removal Procedure

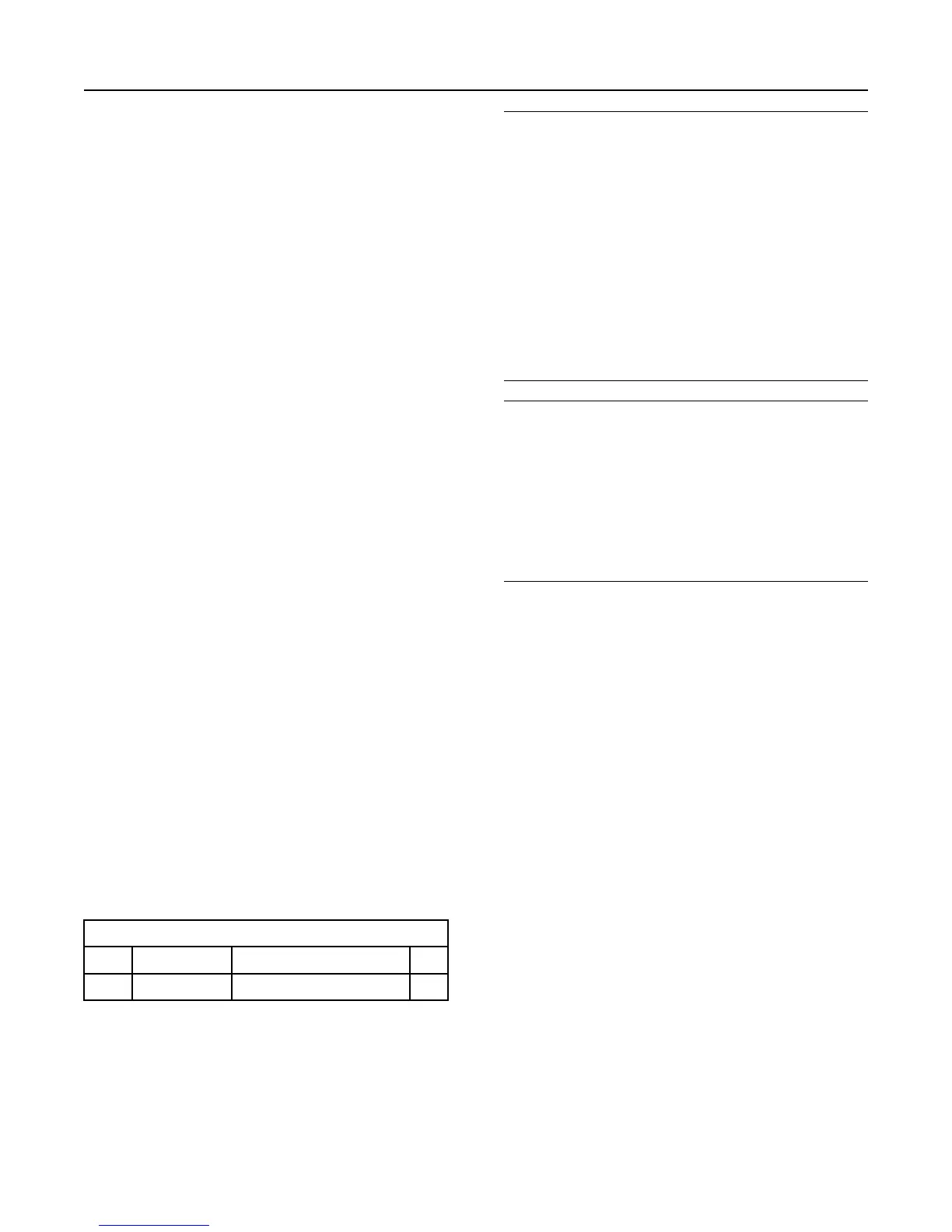

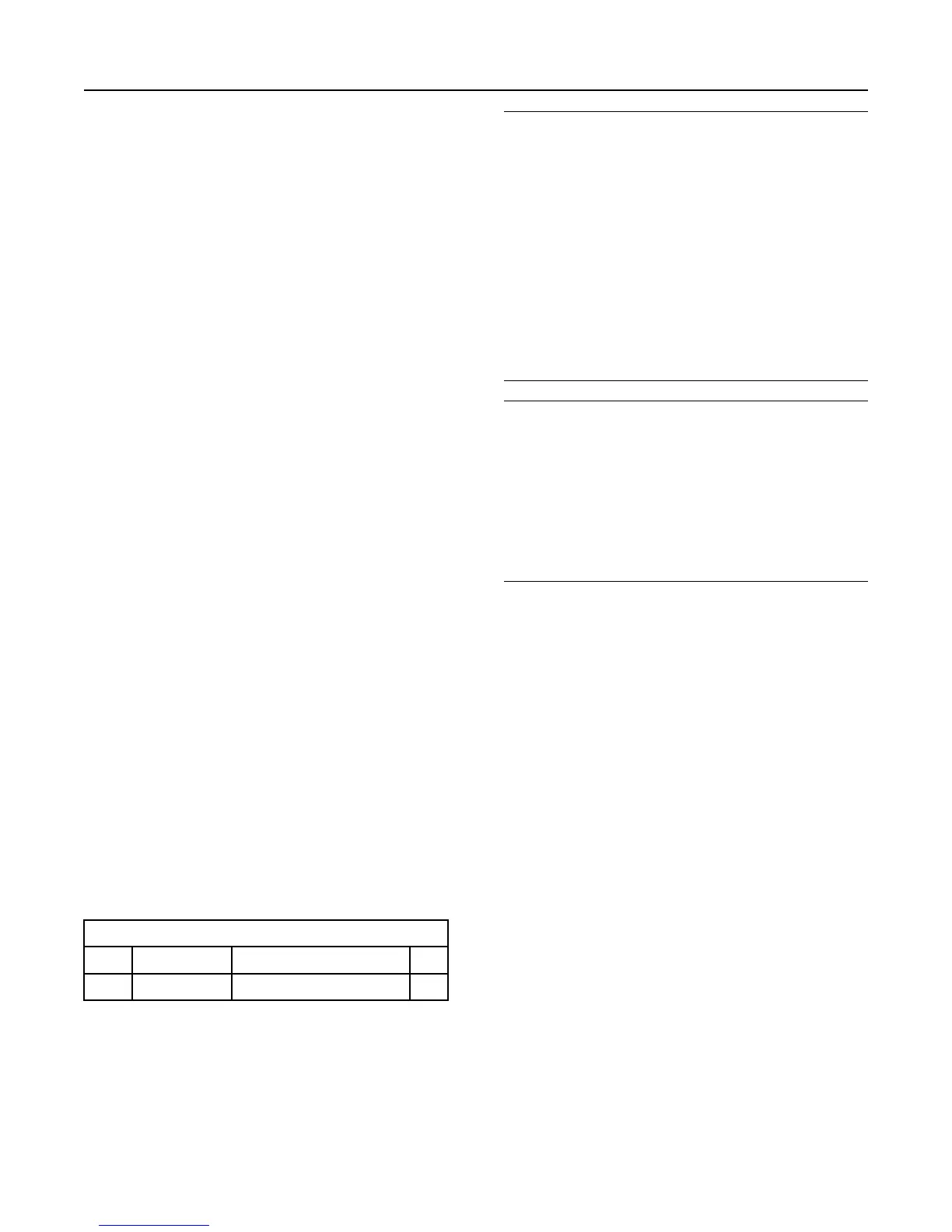

Table 3

Required Tools

Tool Part Number

Part Description Qty

A T412504

Capping Kit

1

NOTICE

Ensure that all adjustments and repairs that are

carried out to the fuel system are performed by

authorized personnel that have the correct

training.

Before beginning ANY work on the fuel system,

refer to Operation and Maintenance Manual, “Gen-

eral Hazard Information and High Pressure Fuel

Lines” for safety information.

Refer to System Operation, Testing and Adjusting,

“Cleanliness of Fuel System Components” for de-

tailed information on the standards of cleanliness

that must be observed during ALL work on the

fuel system.

NOTICE

Care must be taken to ensure that fluids are con-

tained during performance of inspection, mainte-

nance, testing, adjusting and repair of the product. Be

prepared to collect the fluid with suitable containers

before opening any compartment or disassembling

any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

1. Turn the battery disconnect switch to the OFF

position.

2. Turn the fuel supply to the OFF position.

3. Drain the secondary filter. Refer to Operation and

Maintenance Manual, “Fuel System Secondary

Filter - Replace” for the correct procedure.

8 UENR4503

Disassembly and Assembly Section

Loading...

Loading...