Chapter 4 TPD1379EDGr

30

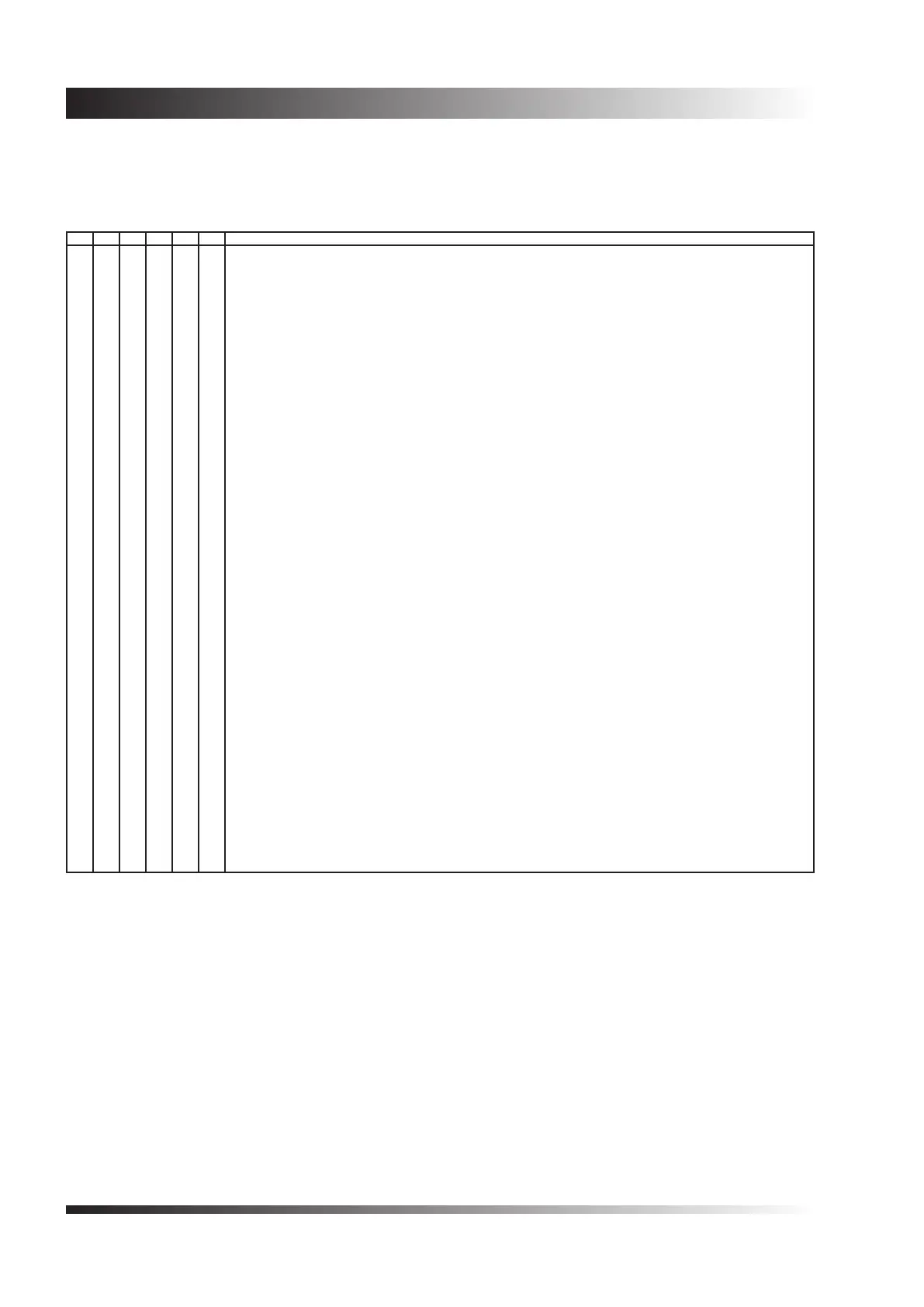

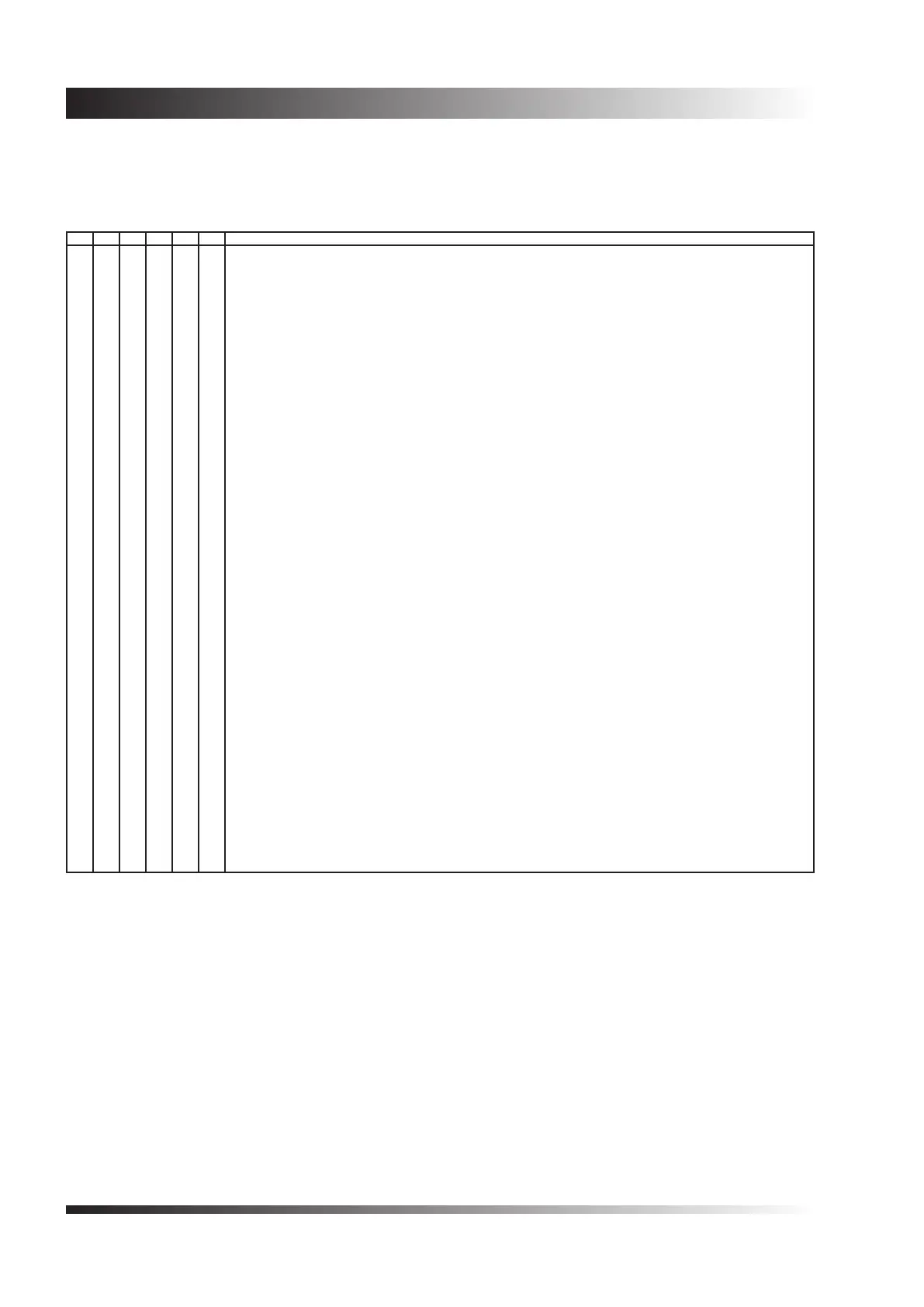

Schedules

The schedules which follow must be applied at the interval (hours or months) which occur rst.

A. First service at 25/50 hours D Every 1000 hours

B. Every day or every 8 hours E Every 2000 hours

C. Every 500 hours or 12 months F Every 3000 hours

A B C D E F Operation

●

Check the amount of coolant in the header tank

●

Check the engine for leakage of oil and coolant

●

Check the specic gravity of the coolant (2) (3)

● ●

Check the tension and the condition of the drive belt

●

Check the impeller of the raw water pump

●

Check the sea water strainer

● ●

Drain water from the fuel pre-lter (1)

●

Renew the element / canister of the fuel lter

●

Check the atomisers, always renew the clamps (2)

●

Check and adjust the idle speed, if it is necessary (2)

●

Check the amount of lubricating oil in the sump

●

Check the lubricating oil pressure at the gauge

●

Renew the engine lubricating oil (4)

●

Renew the canister of the lubricating oil lter

●

Check the amount of lubricating oil in the reverse gearbox

● ●

Renew the lubricating oil in the reverse gearbox

●

Remove and clean the pipe(s) for the engine breather

●

Renew the engine breather (2)(6)

●

Clean or renew the element of the air lter

●

Check all hoses and connections

● ●

Check the valve tip clearances of the engine, and adjust if necessary (2)

●

Clean the tubocharger impeller and turbocharger compressor casing(2)

●

Check the audible warning system which protects the engine

●

Check the alternator, the starter motor and the turbocharger etc.(2)

●

Check the glow plugs (2) (5)

●

Check the engine mounts

●

Inspect the electrical system for signs of damage (2)

(1)If one is tted.

(2)By a person who has had the correct training.

(3)Renew the antifreeze every 2 years. If a coolant inhibitor is used instead of antifreeze, it should be renewed every 6 months.

(4)The oil change interval will change with the amount of sulphur in the fuel (see the table and the Fuel Specication in section 5). The

interval to change the canister of the lubricating oil lter is not affected.

(5)If the cold start wiring kit is tted.

(6)M65 engines: Renew the breather components every 2000 hours, see page 55. M85T engines: Renew the engine breather valve

assembly every 5000 hours, see page 57.

Note: To ensure that the engine runs at maximum efciency, the operations that follow must be done every 12 months or less. If the raw

water is excessively contaminated, these operations should be done more frequently.

• Clean the tube stack of the heat exchanger for the closed circuit coolant

• Clean the tube stack of the oil cooler for the reverse gearbox.

Loading...

Loading...