perma STAR CONTROL TIME

- 15 -

7.3.1 Examples for determining proper dip switch settings to achieve optimal

lubrication

In the “normal mode” (per 100 operating hours)

Example 1:

A roller bearing is to be provided with 14 cm

3

of lubricant every 500 hours of

operation: 14 cm

3

÷ 500 h = 0.028 cm

3

per h = 2.8 cm

3

per 100 h

The discharge table in chapt. 7.3 on page 14 shows that 3 different settings are

possible for each LC unit size

Variation I:

2.78 cm

3

/100 h for a 60 cm

3

LC unit (S60)

Variation II:

2.78 cm

3

/100 h for a 120 cm

3

LC unit (M120)

Variation III:

2.89 cm

3

/100 h for a 250 cm

3

LC unit (L250)

At this point, you can calculate the total discharge life of the LC unit (and the ex

change date). Proceed as following:

The roller bearing to be lubricated is installed in a machine which runs 5 days per

week 8 hours per working day.

To Variation I: 60 cm

3

LC unit (S60)

2.78 cm

3

/100 h = 0.0278 cm

3

/h

60 cm

3

: 0.0278 cm

3

/h = 2158.3 h

2158.3 h : 40 h/week = 54 weeks

The lubricant is sufcent for more than 1 year, not including additional operational

breaks or any other machine standstills.

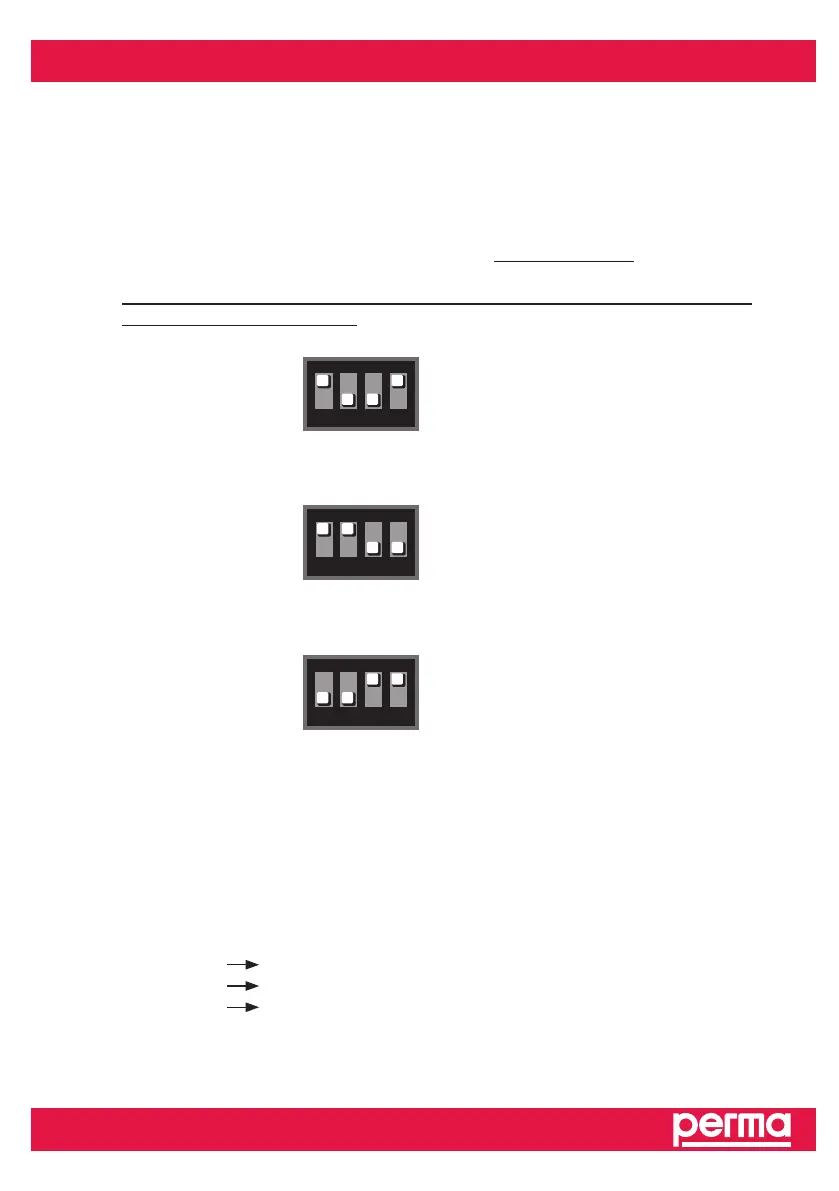

Vol.Time

3

4

1 2

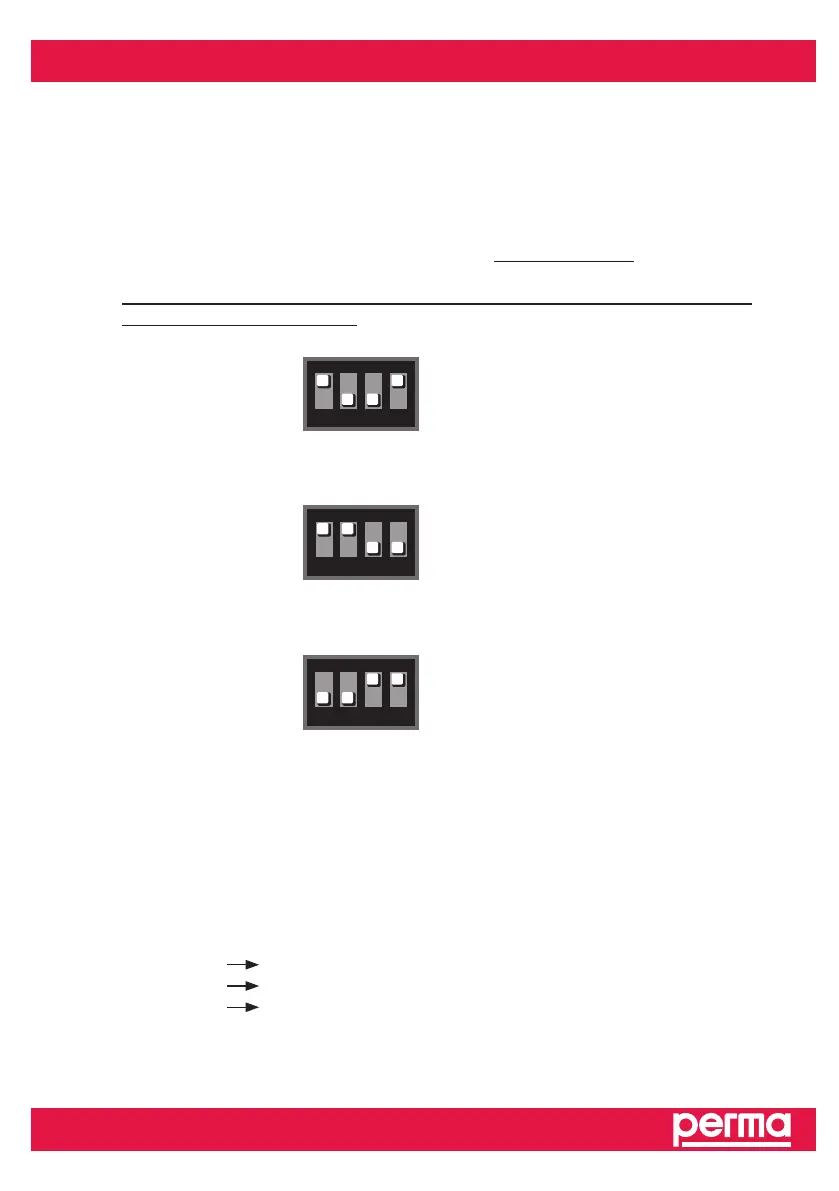

Vol.Time

3

4

1 2

Vol.Time

3

4

1 2

Loading...

Loading...