32. Adjusting

the

Needle

Position

Pfaff 238 machines normally are

set

to make zigzag stitches which extend the same

distance

from

the zero position both ways (central needle position). To check this set

ting,

set

knob G on "0" and put lever H in notch

II

(Fig. 20). Place a piece of thin card

board under the sewing fool and rotate the balance wheel toward you

until

the needle

stitches

into

the

cardboard

lightly. Flick

knob

G to

"4",

rotate

the

balance

wheel

for

ward, then backward, and let the needle,

descending

on the right and left of its throw,

stitch into the cardboard

lightly.

The setting is correct if the right and left punctures are

equidistant

from

the

central

puncture.

To adjust, loosen

set

screw 1 (Fig. 37) and turn eccentric stud h to the right or left, as

appropriate.

Then

tighten

set

screw

i

securely.

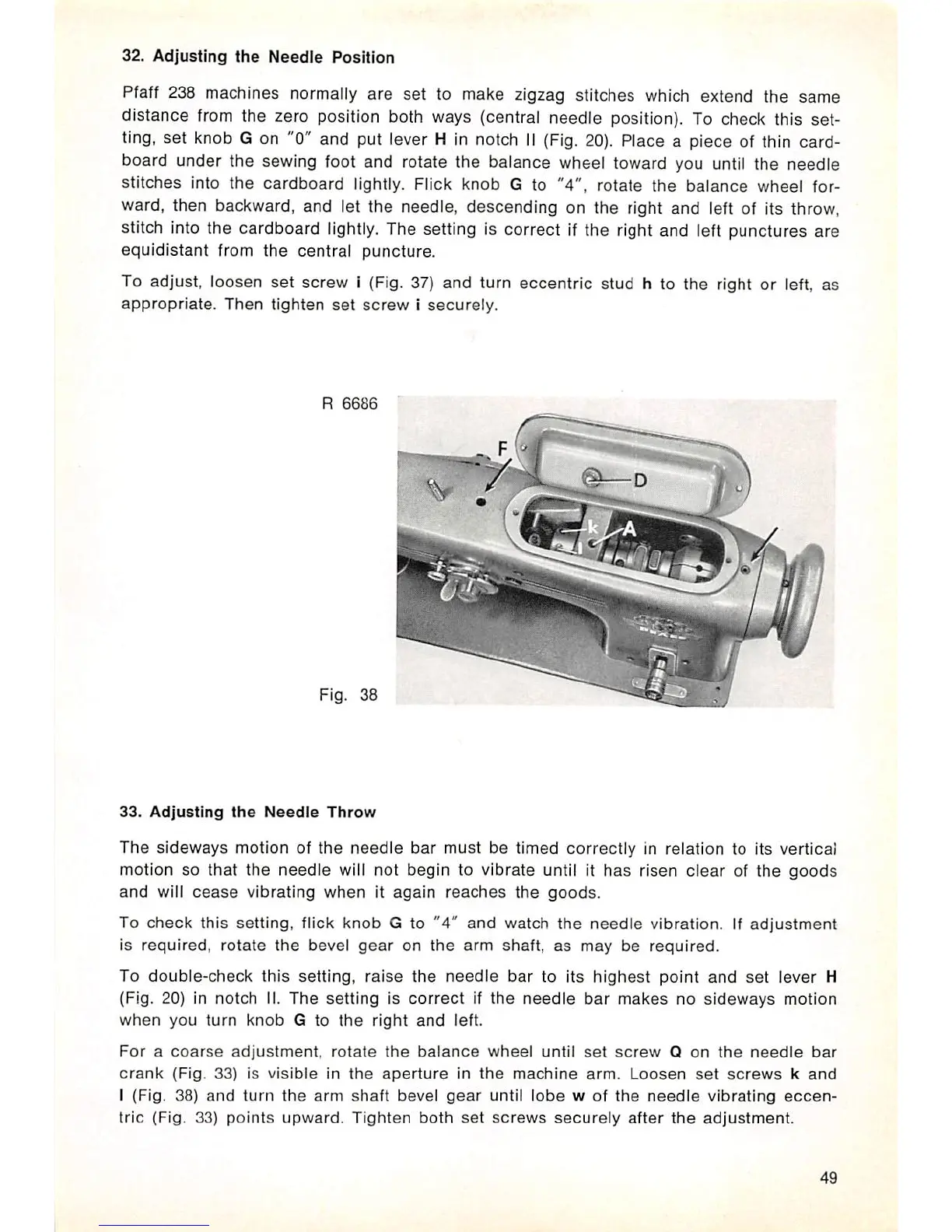

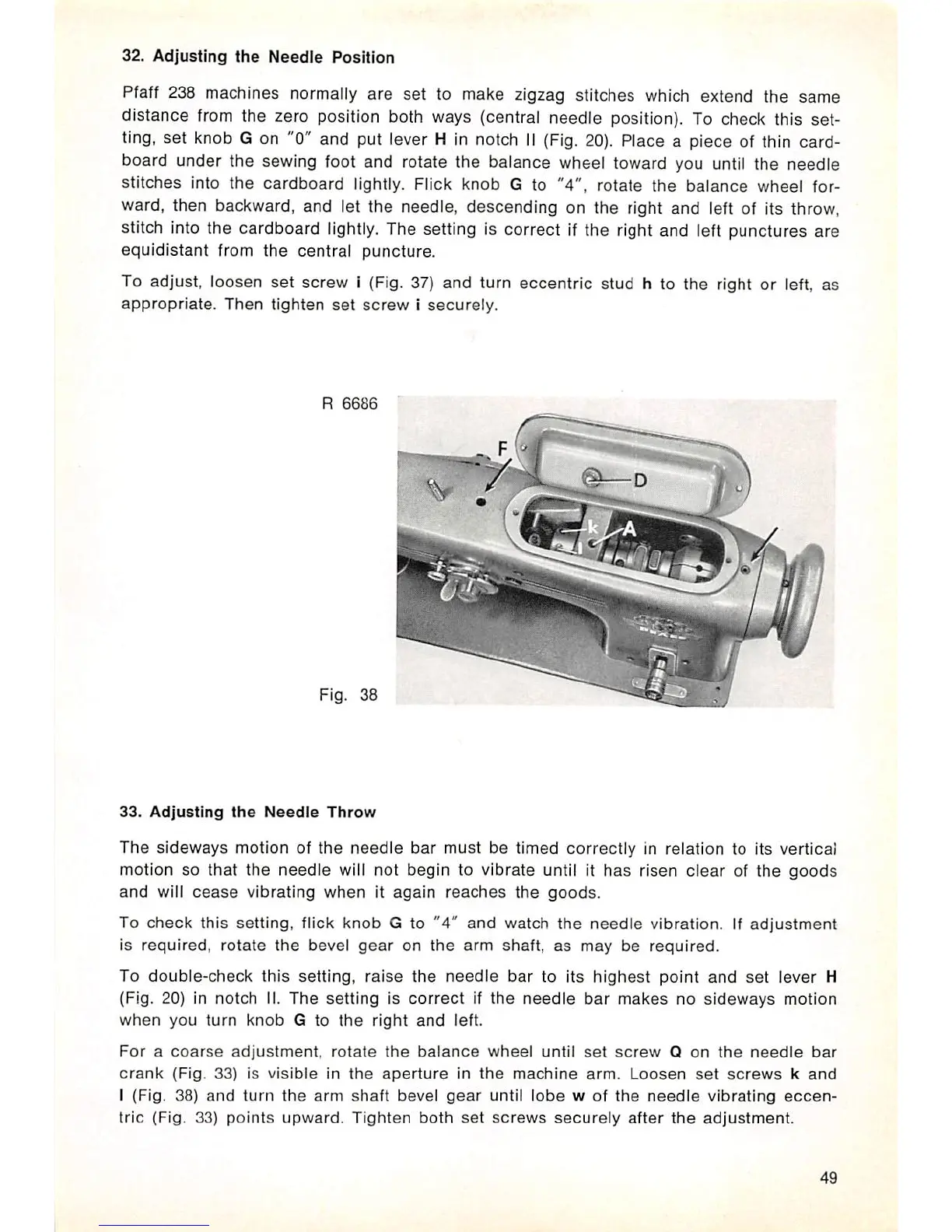

R

6686

Fig. 38

33.

Adjusting

the

Needle

Throw

The

sideways

motion

of

the

needle

bar

must

be

timed

correctly

in

relation

to Its

vertical

motion so

that

the

needle

will not begin to vibrate until it

has

risen

clear

of

the

goods

and

will

cease

vibrating

when

it

again

reaches

the

goods.

To

check

this setting, flick knob G to "4"

and

watch

the

needle

vibration. If

adjustment

is required,

rotate

the

bevel

gear

on

the

arm shaft,

as

may be required.

To

double-check

this

setting,

raise

the

needle

bar

to Its

highest

point

and

set

lever

H

(Fig. 20) In

notch

II.

The

setting

is

correct

if

the

needle

bar

makes

no

sideways

motion

when

you

turn

knob

G to

the

right

and

left.

For

a

coarse

adjustment,

rotate

the

balance

wheel

until

set

screw

Q

on

the

needle

bar

crank

(Fig.

33)

is

visible

In

the

aperture

in

the

machine

arm.

Loosen

set

screws

k

and

I (Fig. 38)

and

turn

the

arm

shaft

bevel

gear

until

lobe

w of

the

needle

vibrating

eccen

tric (Fig. 33)

points

upward.

Tighten

both

set

screws

securely

after

the

adjustment.

49

Loading...

Loading...