5 Service - Maintenance

5.1 Cleaning

►

Clean the cover(s) with a soft, lint-free cloth and a product that will not damage the paint, painted

surfaces or the labels.

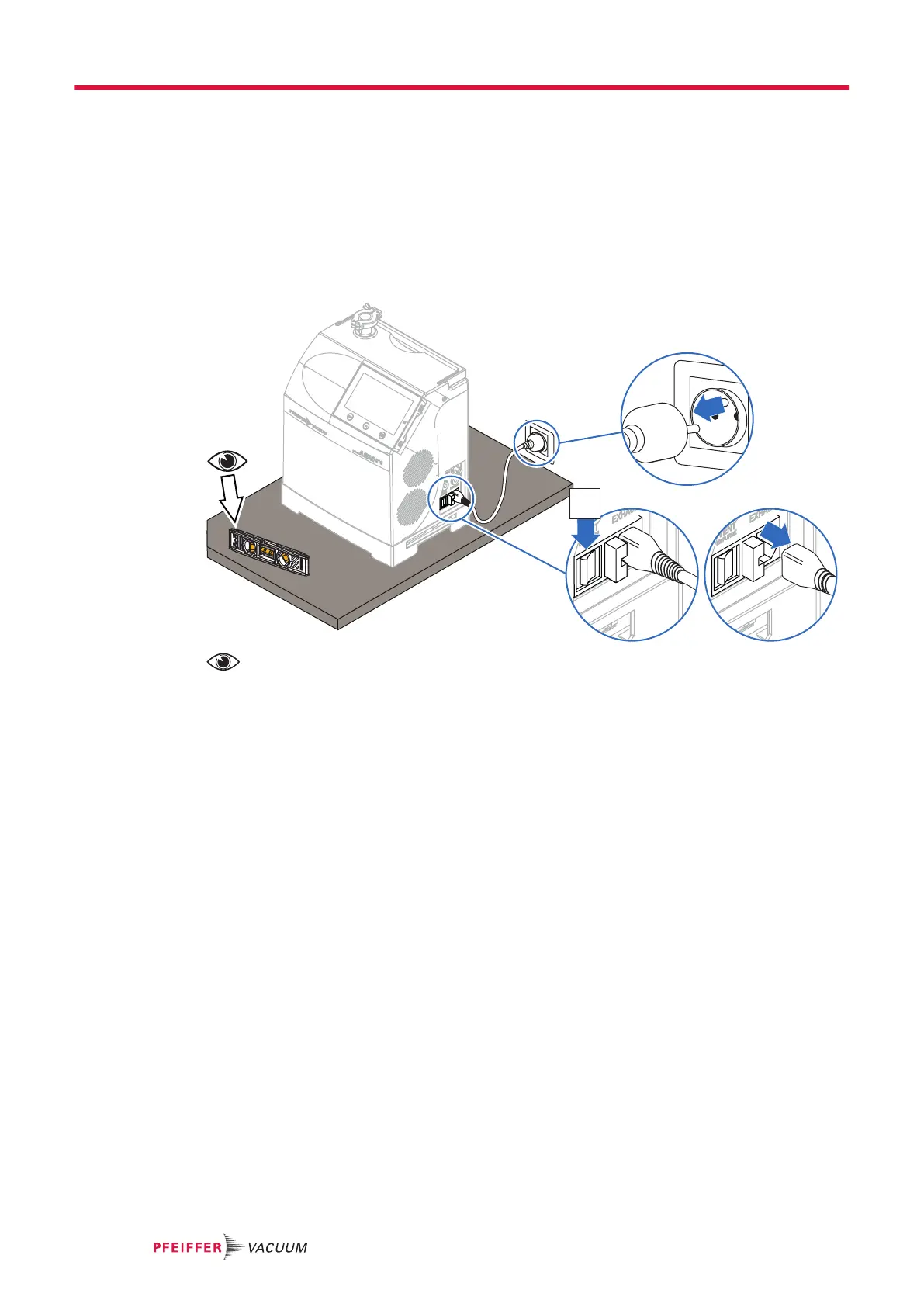

5.2 Detector powering off

The detector is installed on a horizontal work surface.

Pump stop due to power failure

When there is a mains power failure, the detector shuts down: it switches on again automatically when

power is restored.

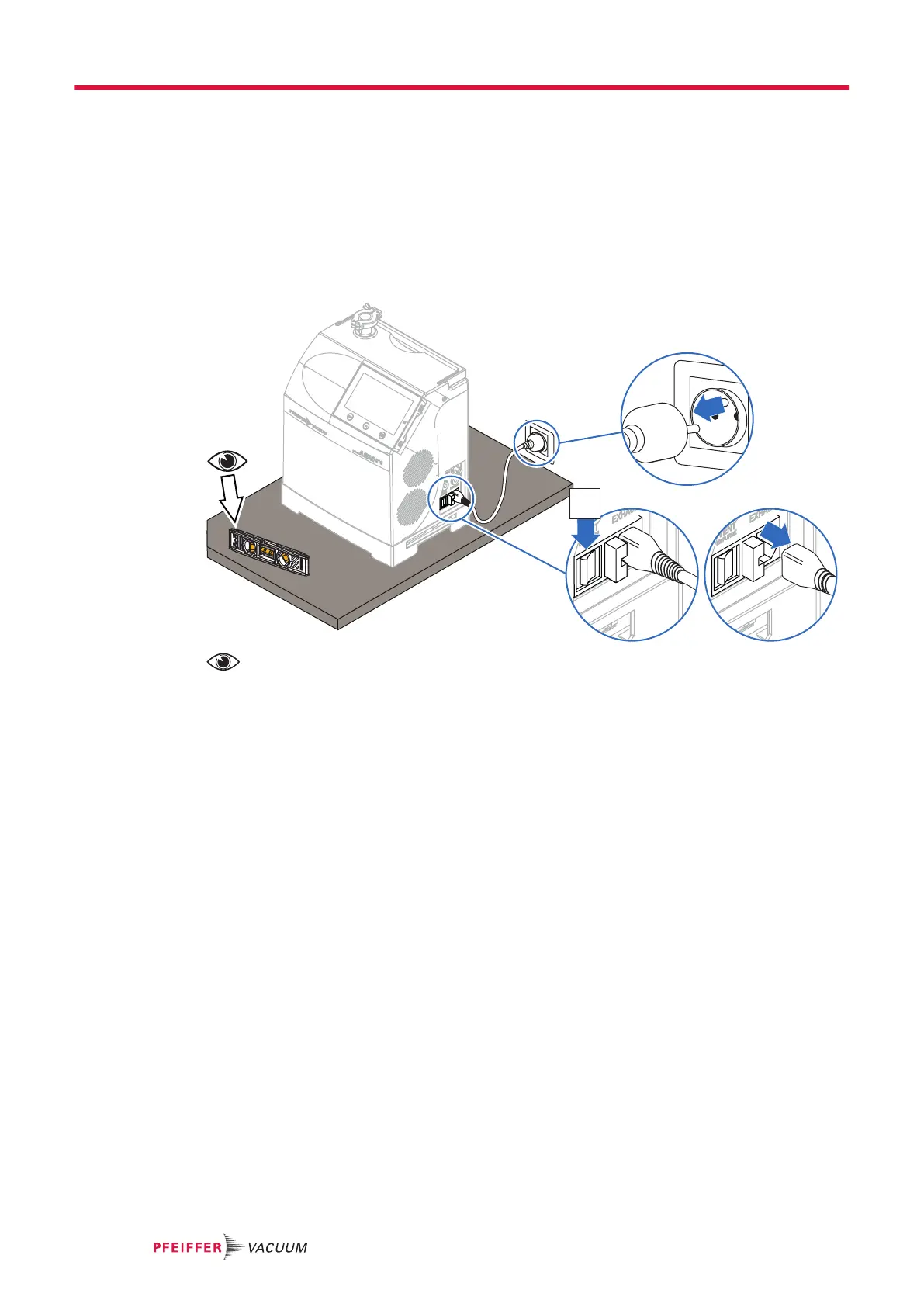

5.3 Air inlet before a maintenance operation

In order to allow the disassembly of vacuum circuit components, an air inlet is a necessary prerequisite.

Stop and vent

To carry out maintenance on vacuum circuit components, the vacuum circuit of the detector must be at

atmospheric pressure.

1. Press [Stop and vent].

●

The turbomolecular pump slows to a speed that allows venting.

●

A message notifies the user when the leak detector can be shut down.

●

If the user does not wish to stop the detector, press [Restart leak detector]. The detector

start-up screen is displayed.

2. Stop the leak detector.

3. Wait until the control panel turns off completely and unplug the mains power cable before working

on the detector.

5.4 Cover disassembly/reassembly

Prerequisite

►

Power off the leak detector (see chapter “Powering Off”).

Service - Maintenance

12/36

Loading...

Loading...