EN – 10

5

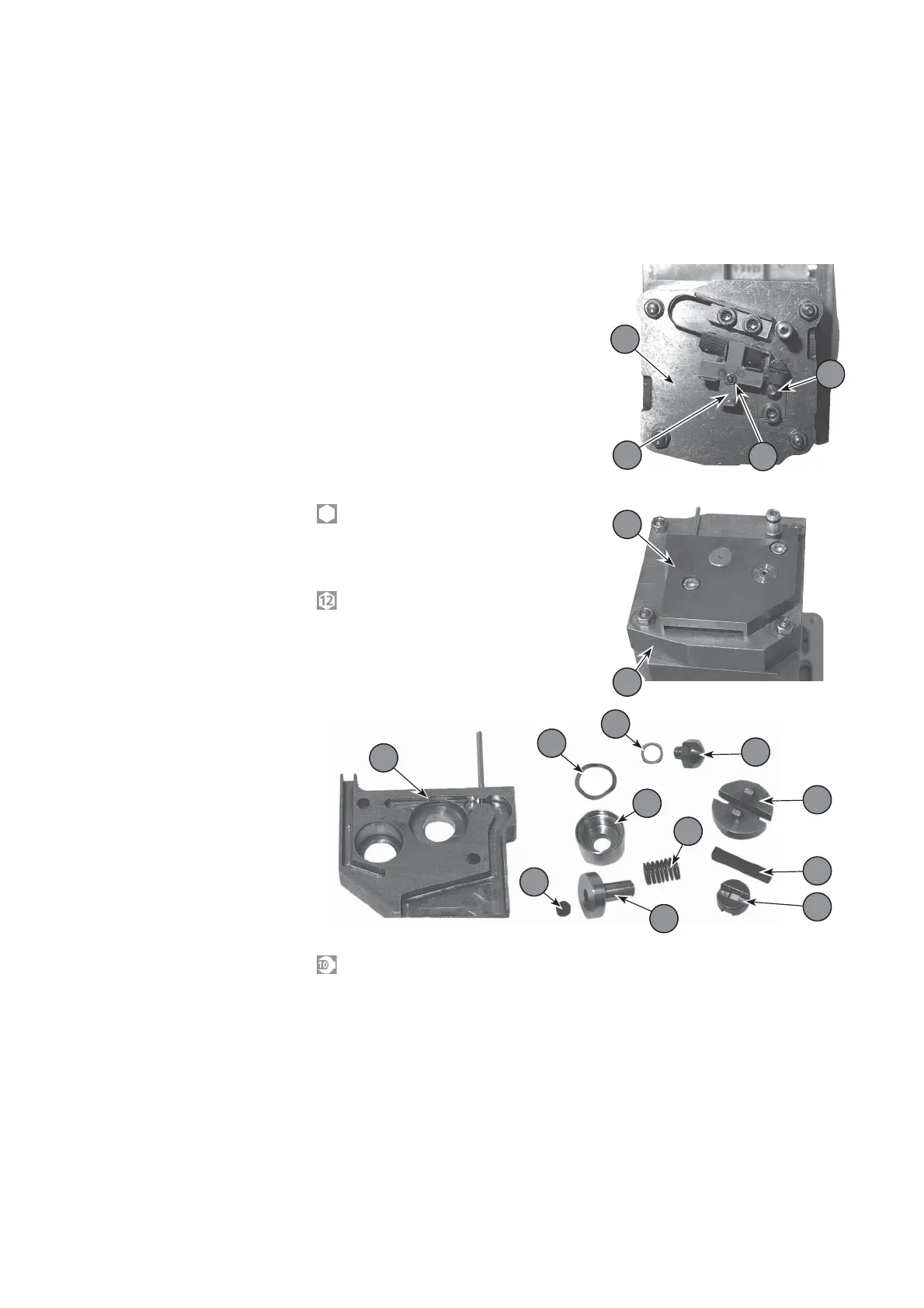

Remove the cover from the oil pump (1).

Release the cylinder (13) equipped with the

washer (14), piston (11) and spring (12).

Release the stop valve (10) from its housing.

In the rear flange, unscrew the seat of

the stop valve (9) and remove the O-ring (8).

Then remove the vane (4), the oil pump

rotor (3) and the Oldham coupling (5).

Disassembling

the pump oil system

I, C1, C2 pumps

and 1015 SD

(

see page N – 14)

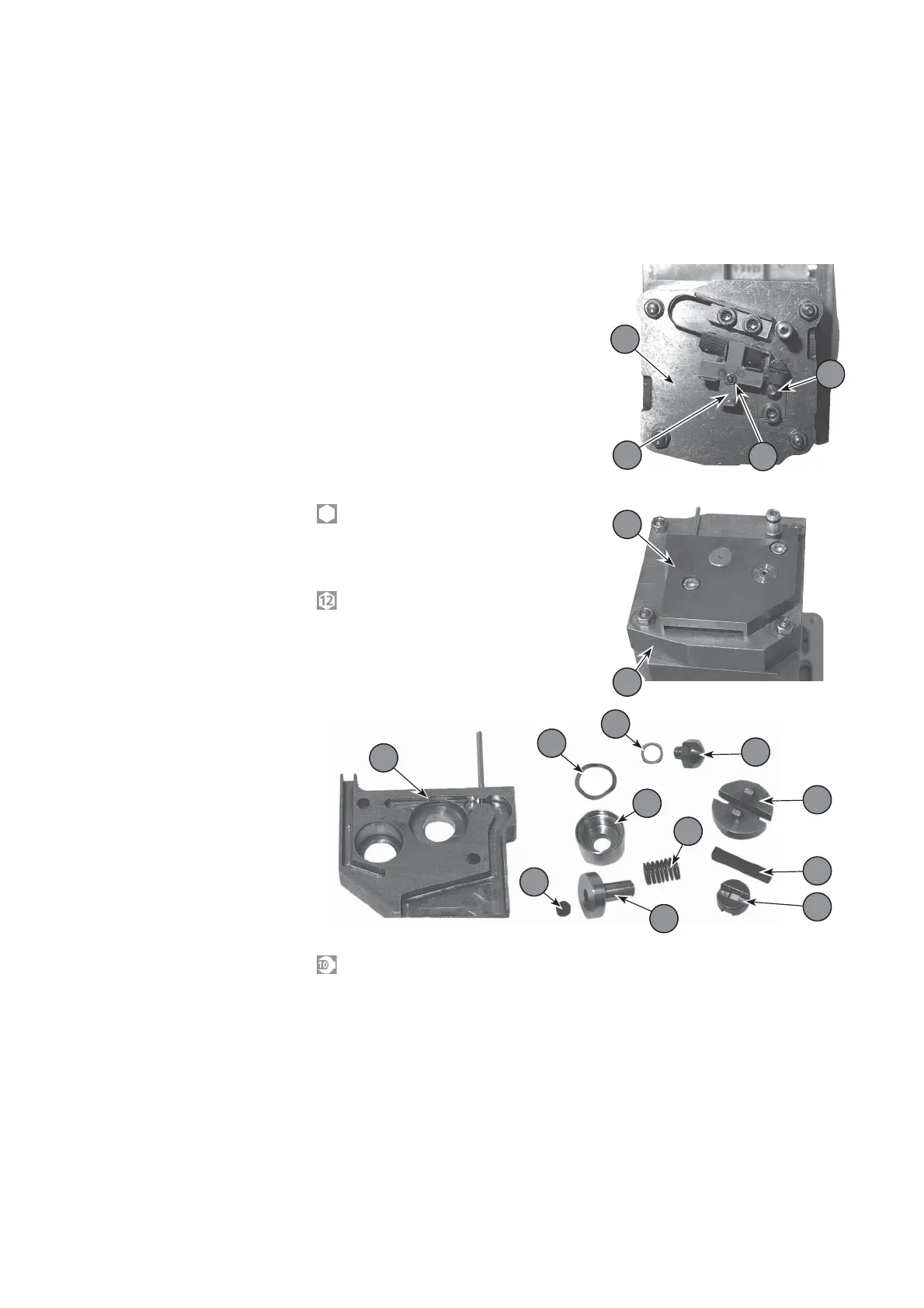

Remove the 4 nuts. Release the flange (7) in the axis.

Disassembling the

rear flange

(see pages N – 14 et N – 16)

1

14

8

9

3

4

5

12

13

10

11

1

7

Disassembling the

SD/SDI pump oil

system

(except 1015 SD)

(see page N – 16)

The oil system is set in the factory,

it must be reset in the event of

disassembly (see reassembly). However, the

rear flange (4) can be disassembled without

modifying the setting.

Remove the spinner-cam (6) by removing the

circlip (7).

Do not disassemble the nozzle (8) to clean

it. During the reassembly, check that it is not

blocked by sending a jet of compressed air

through it.

4

6

7

8

Disassembling the pump (cont’d)

Loading...

Loading...